Tool grinding machine

A technology for sharpening machines and cutting tools, which is applied in the direction of grinding racks, grinding machines, and parts of grinding machine tools. It can solve problems such as difficulty in controlling precision, deepening precision, and affecting grinding efficiency, so as to ensure grinding accuracy and reduce The error of poor precision achieves the effect of multi-angle grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

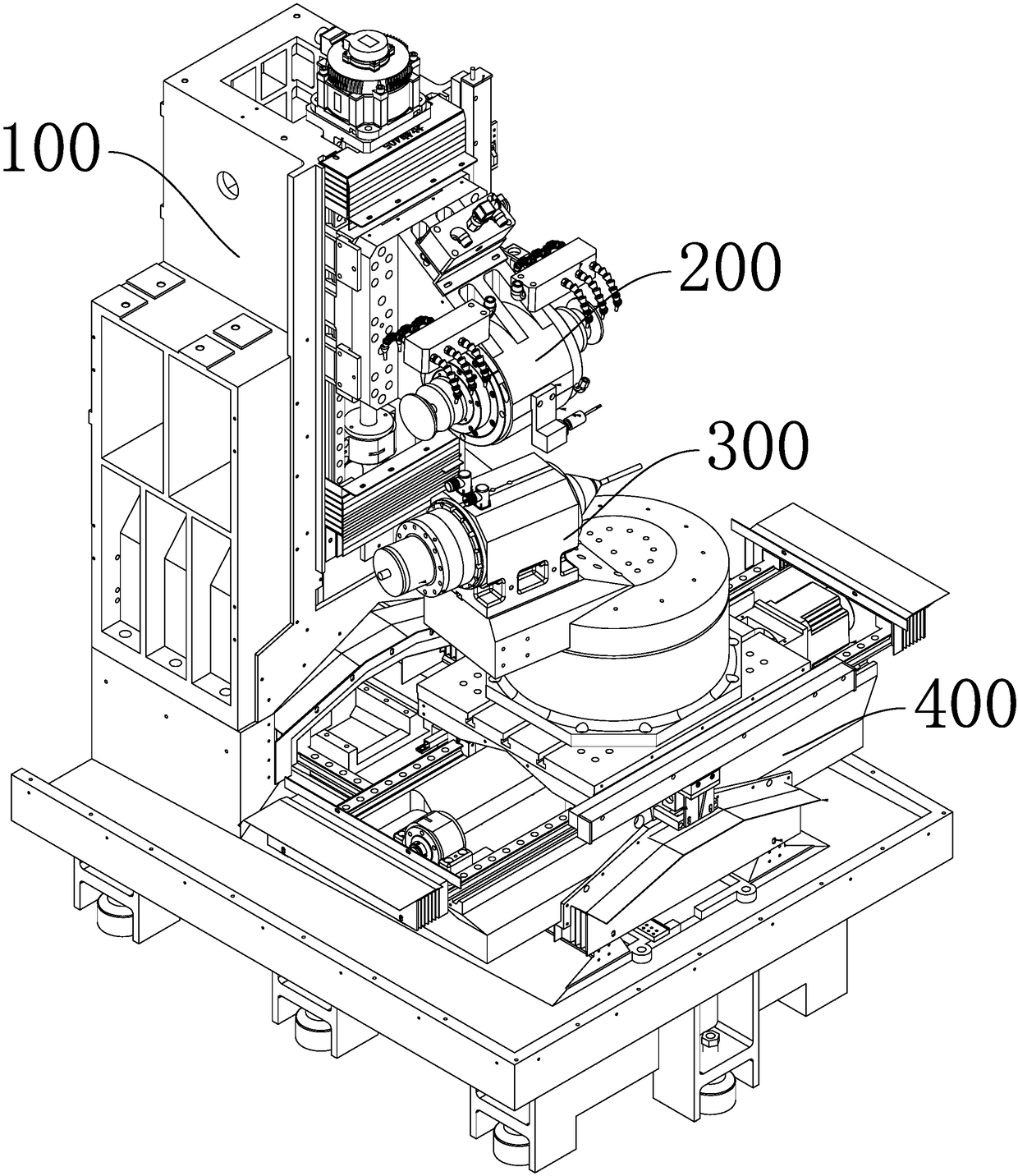

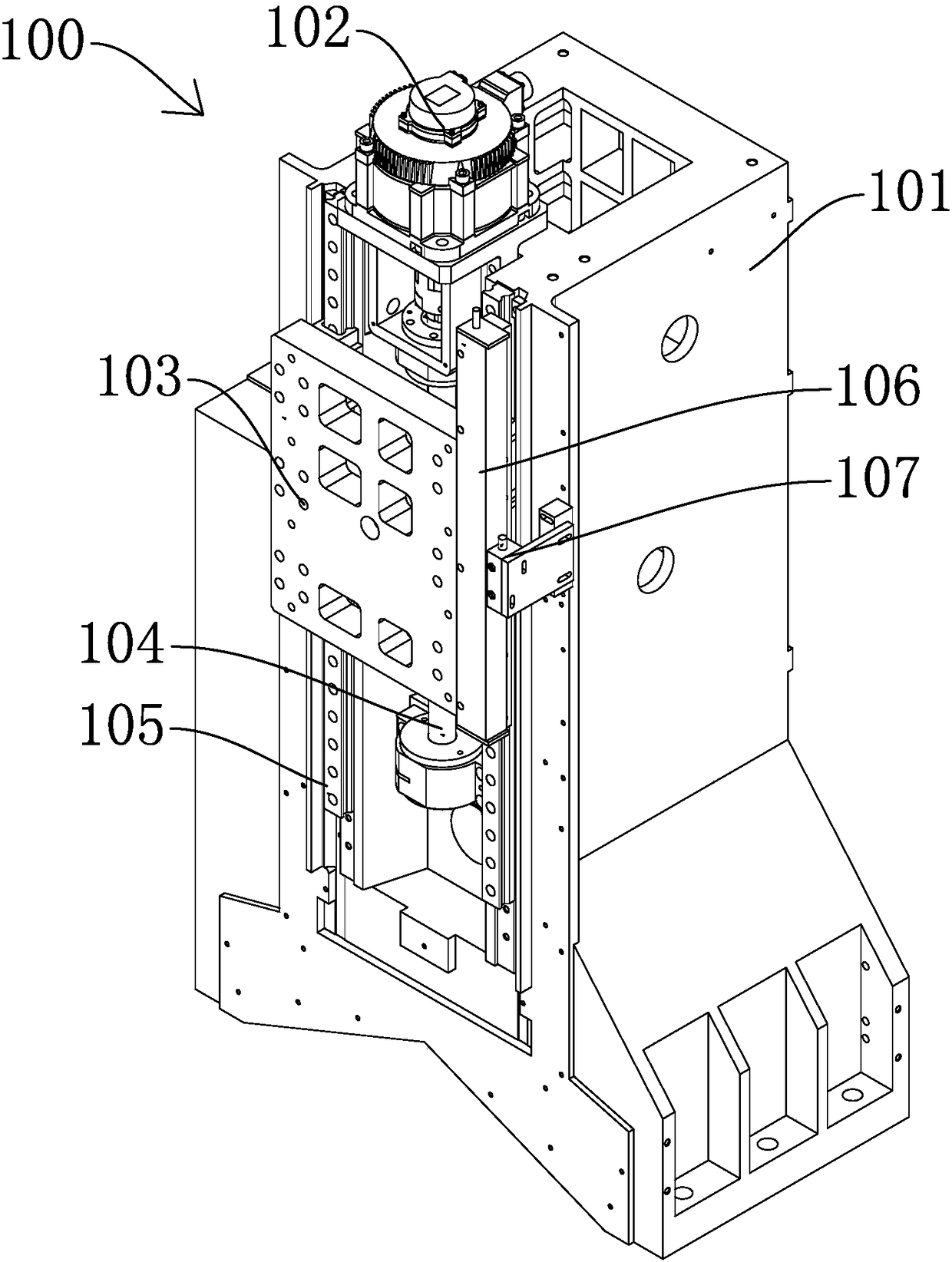

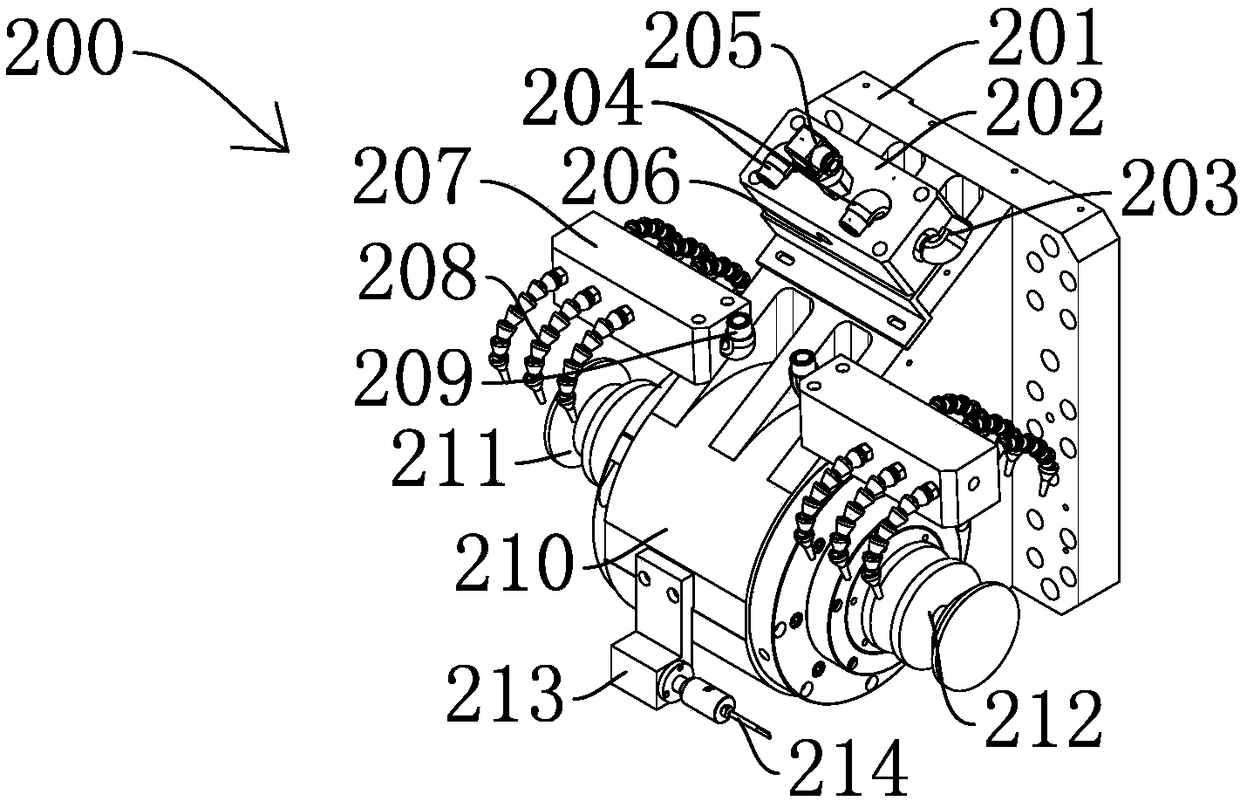

[0023] refer to Figure 1 to Figure 6 As shown, the present invention discloses a sharpening machine, including a grinding assembly 200, a rotary table 300 and a translation table 400, the grinding assembly 200 is suspended above the rotary table 300 through a Z-axis transmission structure 100, and the rotary table 300 Installed on the translational workbench 400, and the rotating workbench 300 is provided with a rotating motor 301 to control the rotation of the cutter. The cutting tool installed on the rotating motor 301 is transferred to different grinding wheels; without disassembling the grinding wheel, the grinding wheel can be switched directly, which improves the efficiency and ensures the sharpening accuracy; specifically, it can be understood that the cutting tool Rotate at any angle of 360 degrees through the rotating table 300, and cooper...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap