Cement stabilized macadam mixture processing method

A technology of cement-stabilized crushed stone and processing method, which is applied in clay processing equipment, cement mixing devices, chemical instruments and methods, etc., can solve the problem of uneven mixing of mixtures and affect the durability and crack resistance performance and life of cement-stabilized crushed stone base. and other problems, to achieve the effect of uniform mixture, saving cement material and easy mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

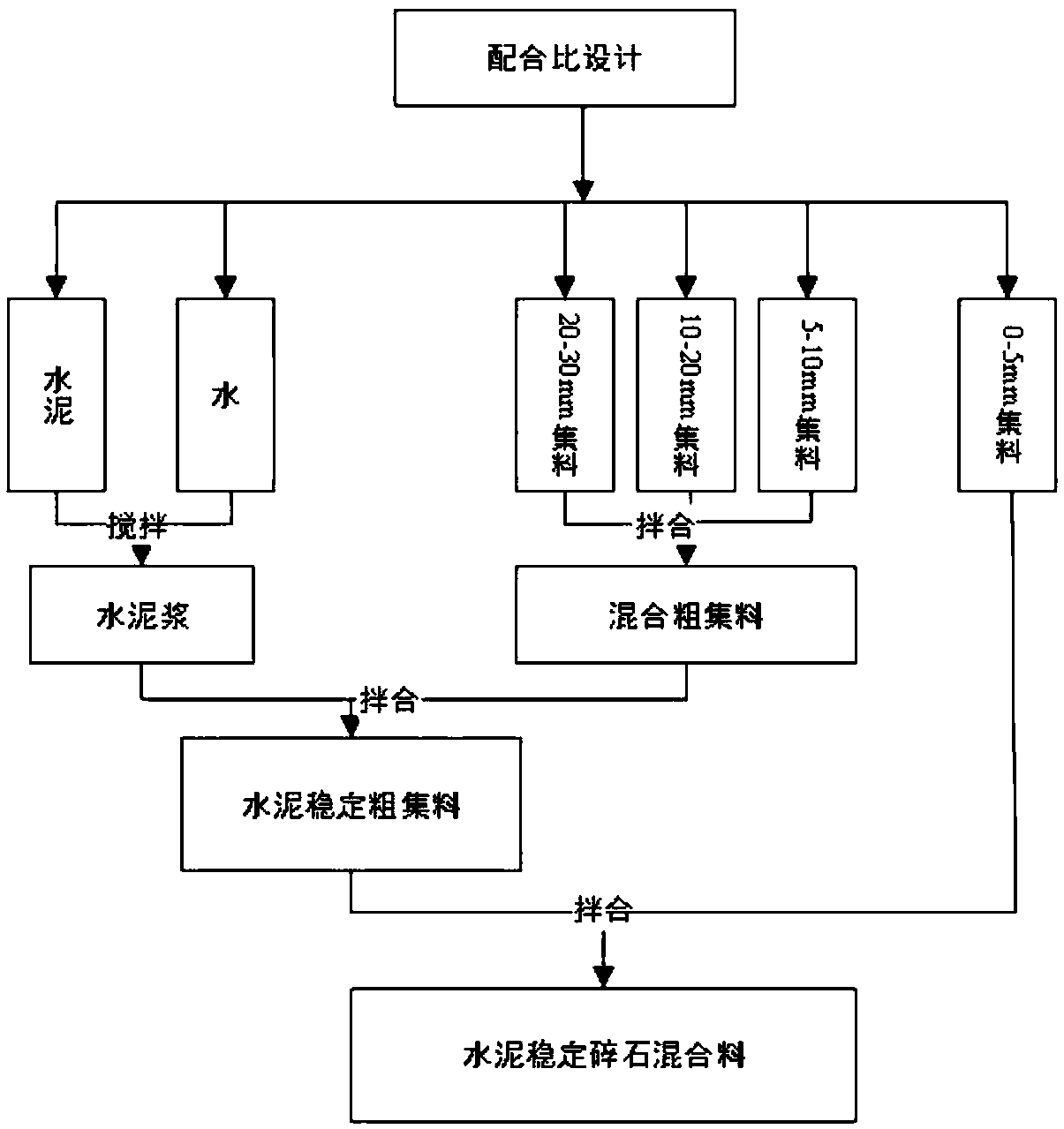

[0031] When designing the mixing ratio of cement-stabilized crushed stone, the method of the invention is used to process the cement-stabilized crushed-stone mixture.

[0032] Raw materials: cement is ordinary Portland cement (P O); coarse aggregate is limestone with a particle size range of 20-30mm, 10-20mm, and 5-10mm; fine aggregate is limestone with a particle size of 0.1-5mm; water is tap water; The material design strength R is 5MPa.

[0033] Mixing ratio design: According to the screening results, the mixed stones are assembled by trial algorithm. After calculation, the gradation of the mixed stones meets the design requirements, and the addition ratio of each grade of aggregate is determined, as shown in the following table:

[0034] Table 1 Design results of aggregate ratio

[0035] Coarse and fine aggregate (mm)

Limestone 20-30

Limestone 10-20

Limestone 5-10

Limestone 0.1-5

percentage(%)

15

28

25

32

[0036] Table 2 ...

Embodiment 2

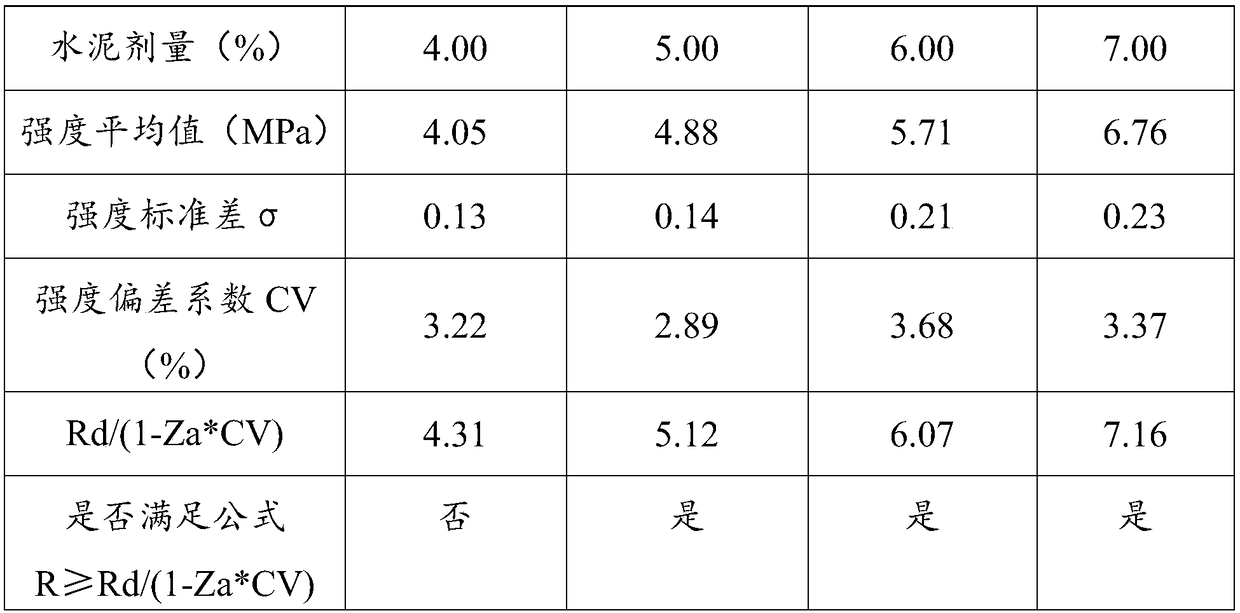

[0104] The method of the invention is adopted to prepare the cement-stabilized crushed stone mixture with the determined mixing ratio, water content and cement consumption, and the strength test is carried out. Test the unconfined compressive strength of the specimen by static pressure forming. The target mix ratio of cement stabilized crushed stone mixture is as follows:

[0105] Table 17 Aggregate ratio design results

[0106] Coarse and fine aggregate (mm)

Limestone 20-30

Limestone 10-20

Limestone 5-10

Limestone 0-5

percentage(%)

15

28

25

32

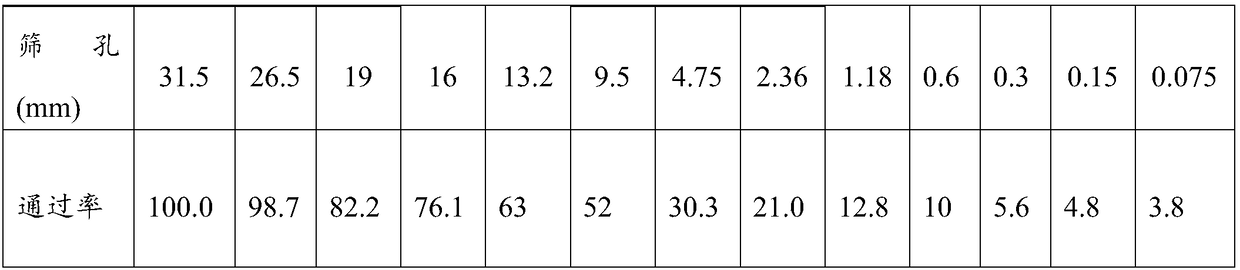

[0107] Table 18 Synthetic Grading Table

[0108] Sieve hole

31.5

26.5

19

16

13.2

9.5

4.75

2.36

1.18

0.6

0.3

0.15

0.075

Passing rate

100.0

98.7

82.2

76.1

63

50

30.3

21.0

12.8

10

5.6

4.8

3.8

[0109] Table 19 Design cement dosage, water content and volume index

[0110] cement t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com