Animal room IVC automatic taking/placing system and method

An automatic and experimental animal technology, which is applied in the direction of transportation, packaging, storage devices, etc., can solve the problems of low work efficiency and high cost of replacement labor, and achieve the effect of improving work efficiency, saving manual labor, and facilitating later function expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

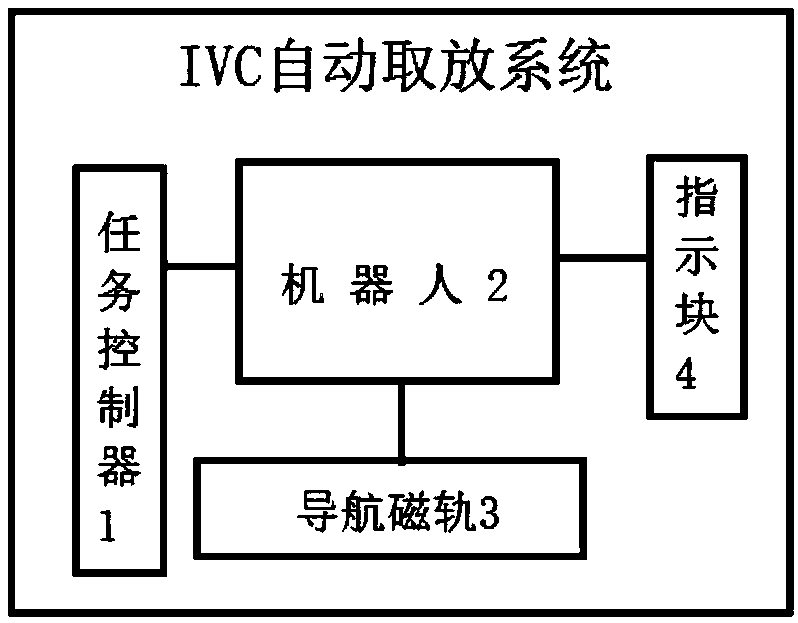

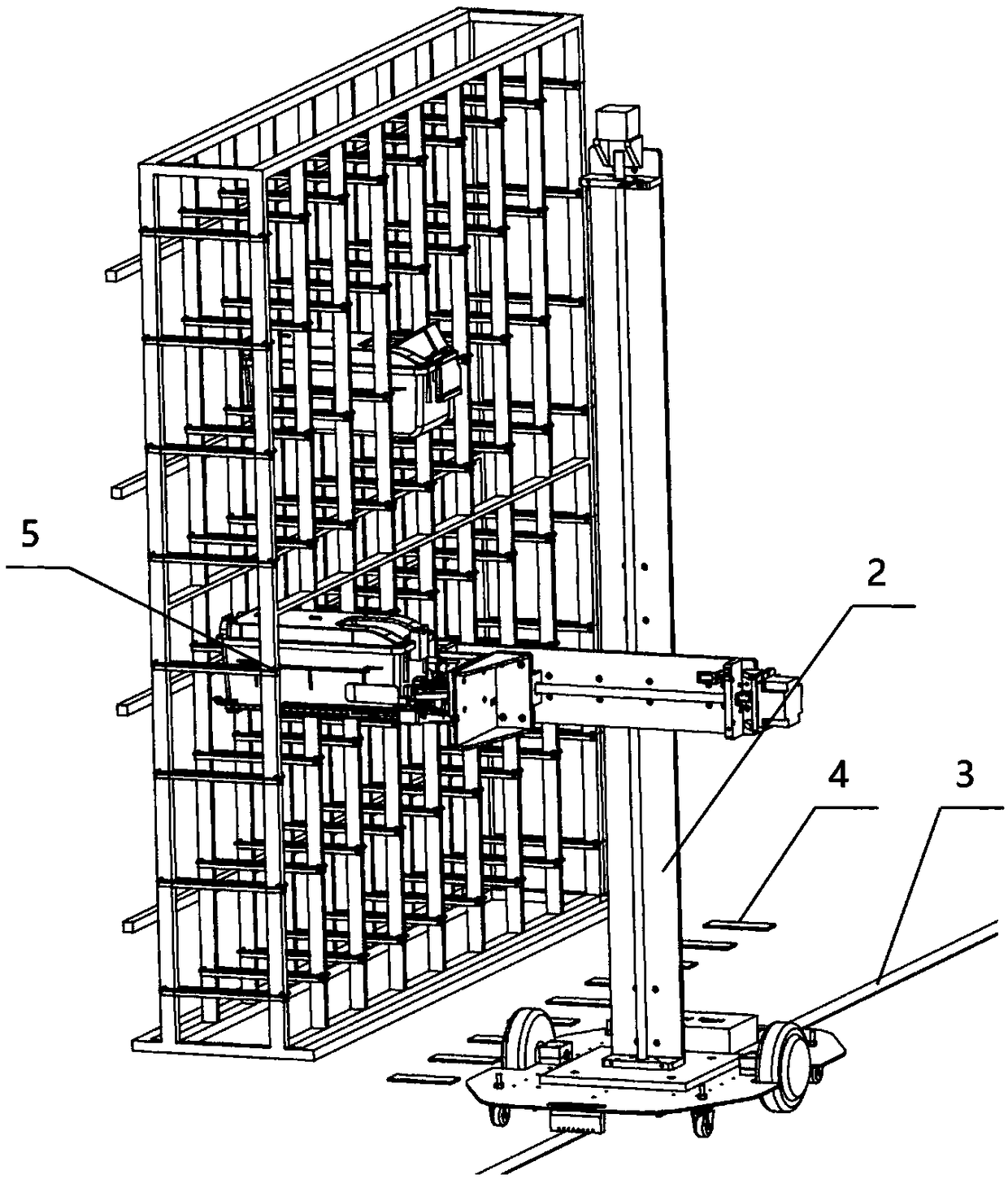

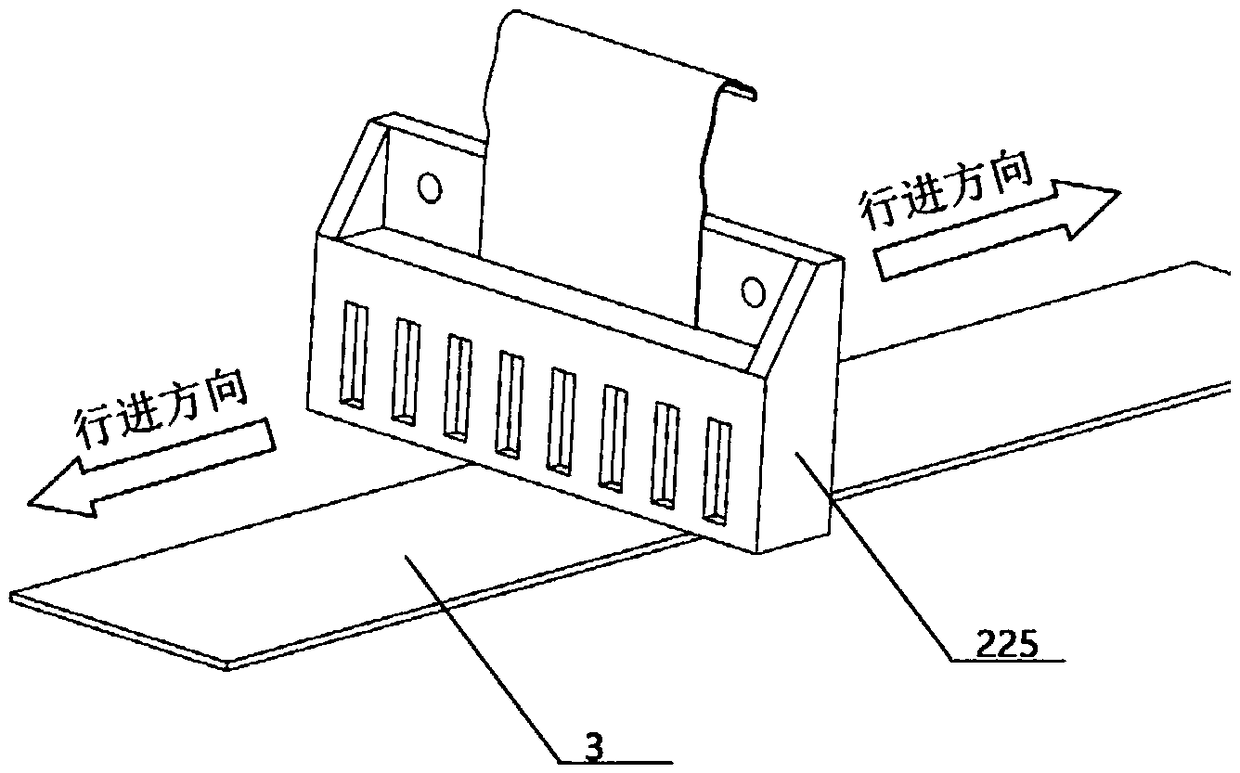

[0074] This embodiment provides an automatic IVC pick-up / place system for experimental animal rooms, figure 1 Shown is a schematic structural diagram of the animal room IVC automatic pick / place system of this embodiment, figure 2 Shown is the model diagram of the IVC automatic pick-up / place system in the animal room of this embodiment. Such as figure 1 and figure 2 As shown, the animal house IVC automatic pick / place system includes: an IVC automatic pick / place robot 2, a navigation magnetic track 3, a column positioning magnetic strip 4, a cage position indicator block 5, and a task controller 1. in,

[0075] The IVC automatic pick-up / place robot 2 is used to receive the pick-up / place task of the task controller 1, moves under the guidance of the navigation magnetic track 3, and interacts with the column positioning magnetic strip 4 to perform coordinate positioning, and coordinates with the cage position indicator block 5 interactively complete the IVC pick / drop quest. ...

no. 2 example

[0127] This embodiment provides a method for automatically taking / putting the IVC in the animal room, which is realized by the system for automatically taking / putting the IVC in the animal room of the first embodiment. Figure 11 Shown is the flow chart of the IVC automatic pick-up / place method of this embodiment. Among them, the moving direction of the robot in the horizontal direction is the x-axis, and the direction perpendicular to the ground (up and down) is the y-axis; the intersection of the x-axis and the y-axis is the origin, and the direction perpendicular to the cage in a horizontal plane is the z-axis. Such as Figure 11 As shown, the method for automatically taking / putting the IVC in the animal room described in this embodiment includes the following steps:

[0128] Step S1, the task controller analyzes which cage to operate on according to the pre-configured work content, and sends the specific positioning information and work content to the robot;

[0129] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com