High Boiler Cracking Process in Polysilicon Production

A high-boiling, polysilicon technology, applied in the direction of silicon compounds, halogenated silicon compounds, halogenated silanes, etc., can solve the problems of unreacted materials that cannot be effectively recycled, increase production costs, and cannot effectively remove solid particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

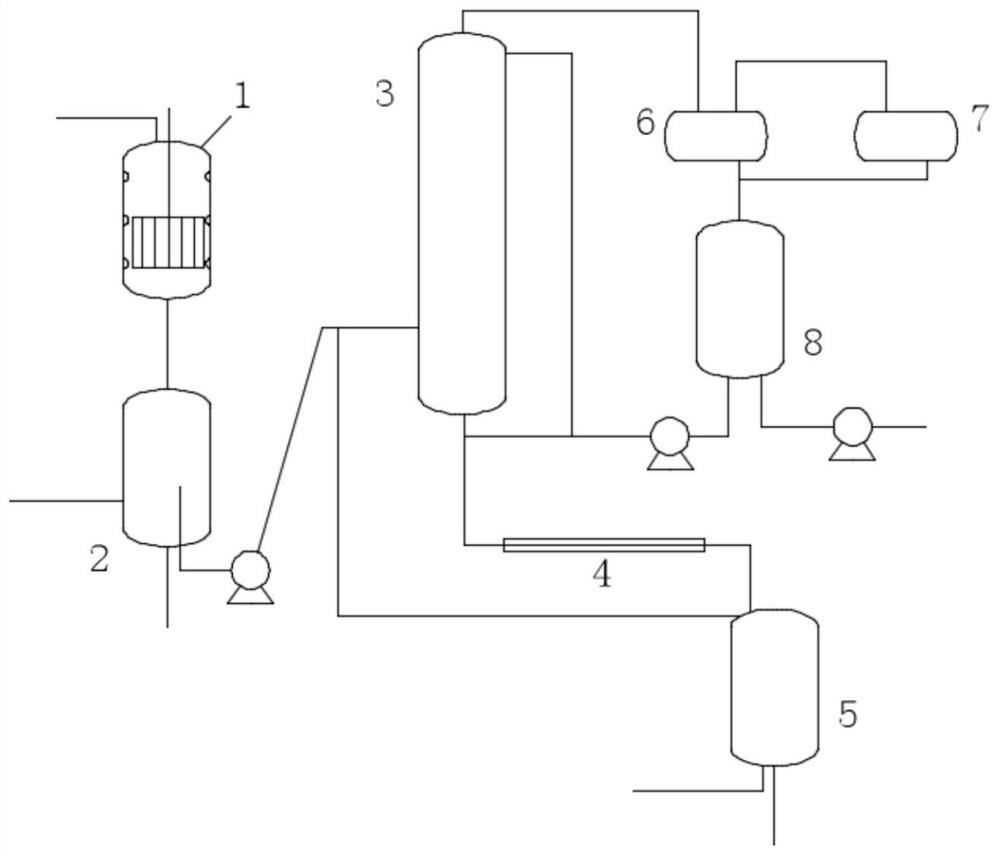

[0035] Such as figure 1 A high-boiler cracking system for polysilicon production can apply the process disclosed in this embodiment, including the following steps:

[0036] Pretreatment: send the high boiling matter into the cooling and stirring tank (1), stir the high boiling matter at low temperature for 1-5 hours, and then send it into the settling tank (2);

[0037] Feed nitrogen into the settling tank (2), discharge the air in the settling tank (2), let the high boilers stand and settle for 1-20 hours under the nitrogen protection environment, and obtain the slurry deposited on the bottom of the settling tank (2) And the first mixture located in the upper layer, the slurry contains solid particles and metal chlorides, is discharged from the bottom, and the first mixture that flows out from the upper layer is sent to the de-elevation tower (3);

[0038] Separation: adjust the pressure in the de-elevation tower (4) to 0.03-0.5Mpa, heat and separate the mixture at 50-150°C,...

Embodiment 2

[0050] The difference from Example 1 is that cracking: the oligomer is sent to the cracking tank after being heated to 80°C by the heat tracing tube;

[0051] Add a catalyst to the cracking tank, adjust the pressure inside the cracking tank to 0.05Mpa, and crack the oligomer into a chlorosilane mixture at 80°C

[0052]

[0053]

Embodiment 3

[0055] The difference from Example 1 is that cracking: the oligomer is sent into the cracking tank after being heated to 120 degrees by the heat tracing tube;

[0056] A catalyst is added into the cracking tank, the pressure inside the cracking tank is adjusted to 0.5Mpa, and the oligomer is cracked into a chlorosilane mixture at 120°C.

[0057]

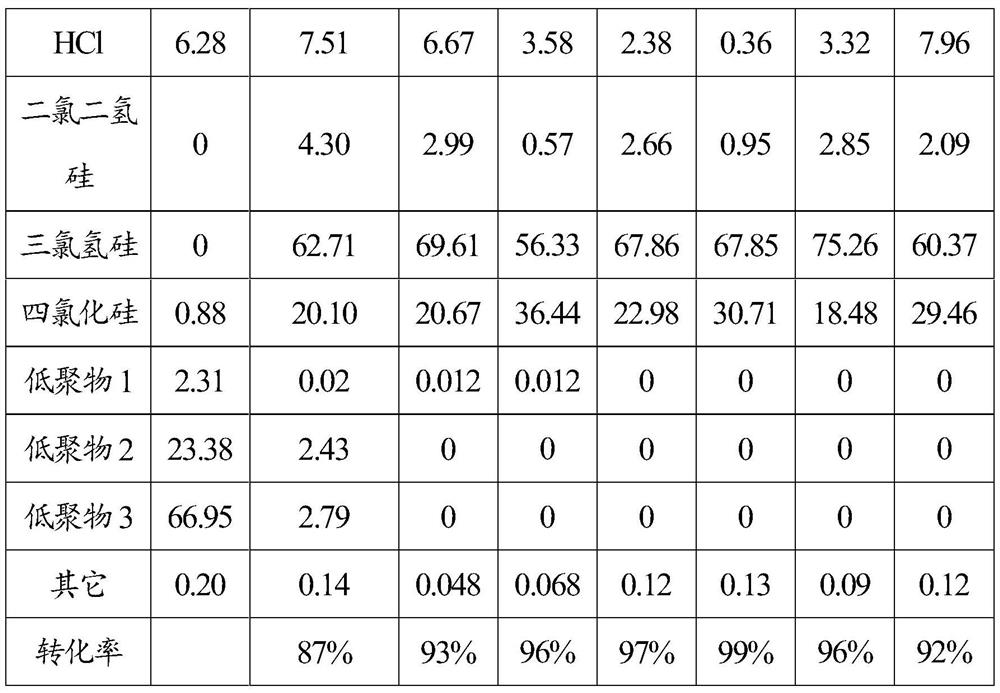

[0058] The process disclosed in the above examples can complete the cracking of high boilers in the polysilicon preparation process by using a single-component catalyst. Compared with the prior art, there is no need to use multi-component catalysts, and the cost of the catalyst is low, and the cracking conversion rate The effect is good. In addition, this process makes full use of system equipment, saves system costs, has less emissions, and has the advantages of environmental protection and high utilization of high boiling substances.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com