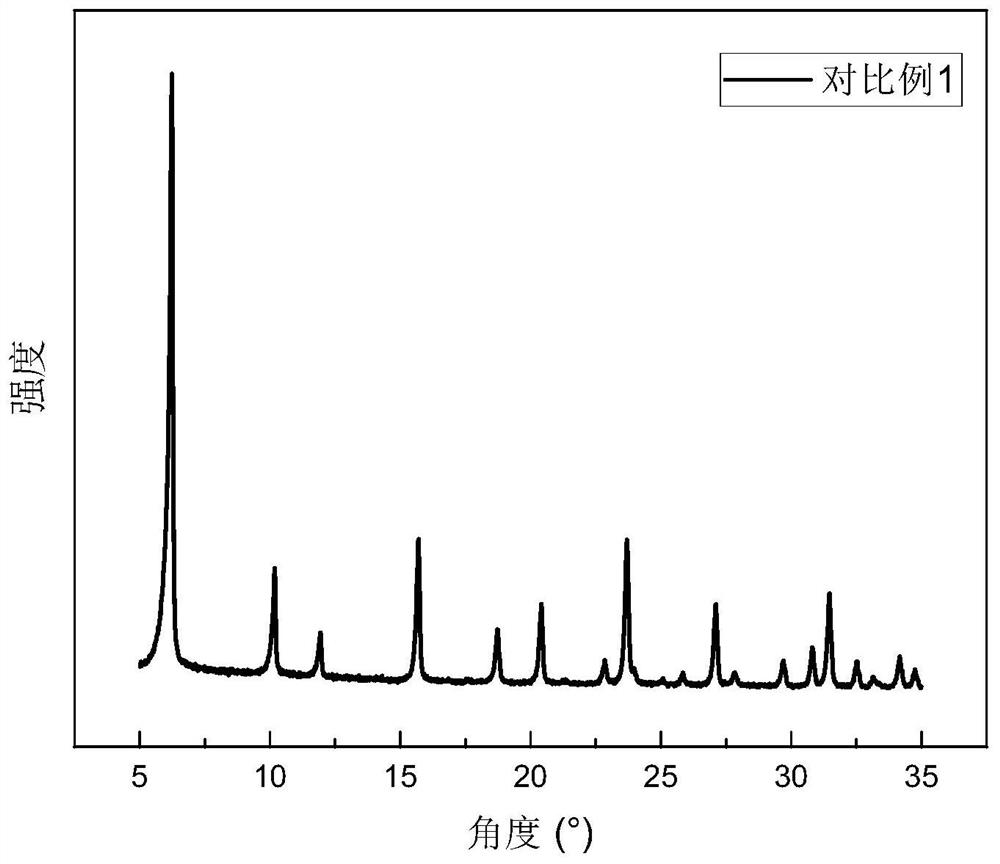

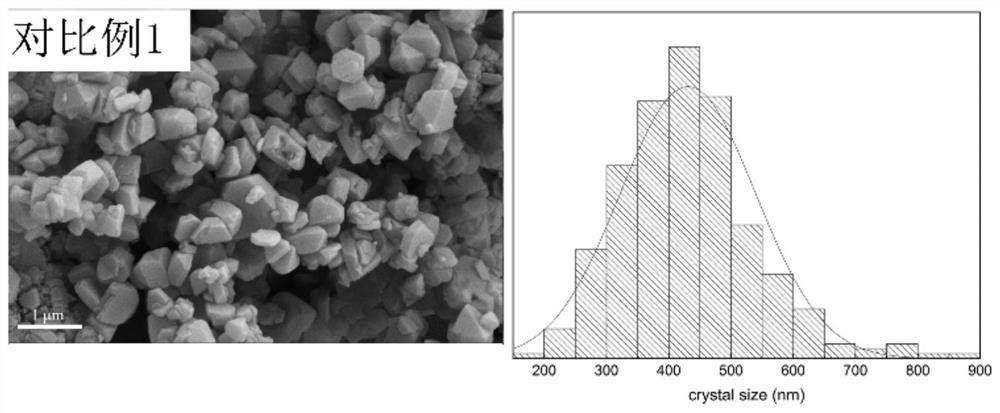

High-silicon small-grain Y-type molecular sieve as well as template-free preparation method and application of same

A small-grain, molecular sieve technology, applied in molecular sieve catalysts, catalyst activation/preparation, chemical instruments and methods, etc., can solve problems such as difficulty in popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

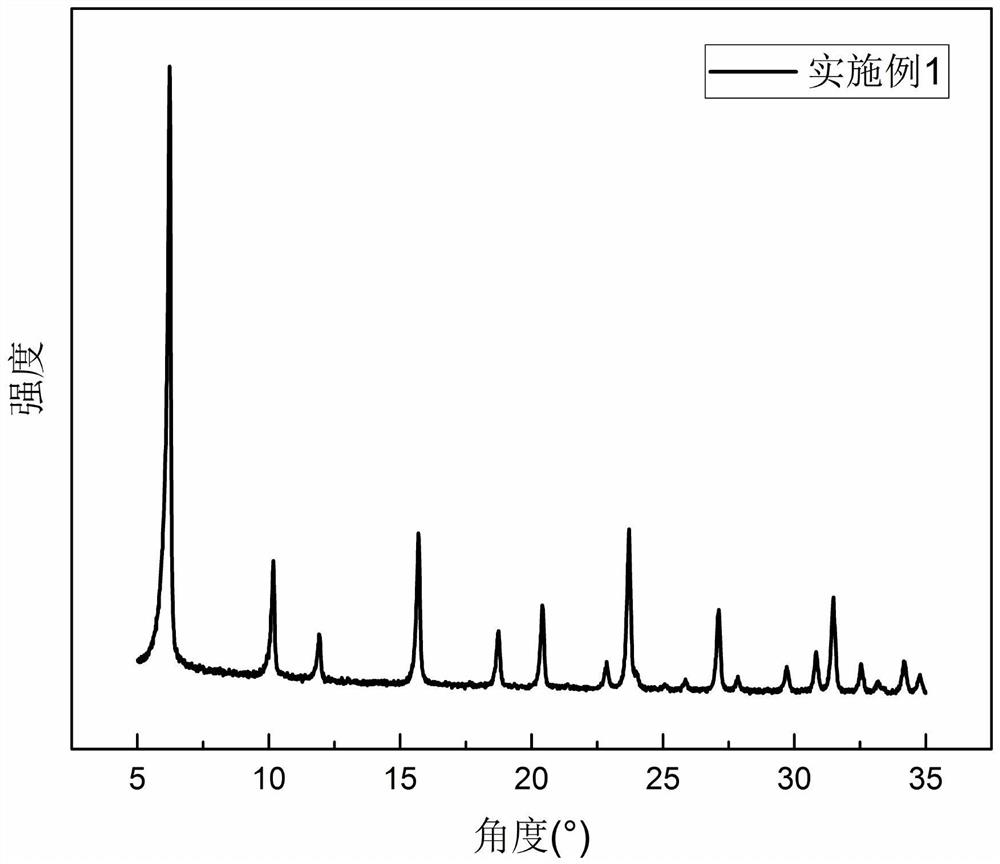

Embodiment 1

[0072] This embodiment provides a high-silicon small-grain Y-type molecular sieve, which is prepared through the following steps:

[0073] 1) According to the molar ratio is Na 2 O: Al 2 o 3 :SiO2 2 :H 2 O=15:1:15:320 to prepare the directing agent

[0074] Under the condition that the temperature of the water bath is 34°C, dissolve 0.05 mol of aluminum sulfate and 1.50 mol of sodium hydroxide in 6 mol of deionized water and stir until completely dissolved to obtain the first mixture, and dissolve 0.75 mol of sodium silicate in 6 Stir in 1 mole of deionized water until completely dissolved to obtain the second mixture, mix the first mixture and the second mixture evenly, add 4 moles of deionized water, stir for 30 minutes, seal and age for a day and night to obtain the directing agent (the directing agent is colloidal) ;

[0075] 2) Prepare mother liquor

[0076] At a water bath temperature of 50°C, dissolve 4.50 moles of sodium hydroxide, 0.86 moles of aluminum sulfate...

Embodiment 2

[0082] This embodiment provides a high-silicon small-grain Y-type molecular sieve, which is prepared by the following steps:

[0083] 1) According to the molar ratio is Na 2 O: Al 2 o 3 :SiO2 2 :H 2 O=15:1:15:320 prepares the directing agent, specifically:

[0084] Under the condition that the temperature of the water bath is 36°C, dissolve 0.05 mol of aluminum sulfate and 1.50 mol of sodium hydroxide in 6 mol of deionized water and stir until completely dissolved to obtain the first mixture, and dissolve 0.75 mol of sodium silicate in 6 Stir in 1 mole of deionized water until completely dissolved to obtain the second mixture, mix the first mixture and the second mixture evenly, add 4 moles of deionized water, stir for 30 minutes, seal and age for a day and night to obtain the directing agent (the directing agent is colloidal) ;

[0085] 2) Prepare mother liquor

[0086] At a water bath temperature of 55°C, dissolve 7.5 moles of sodium hydroxide, 0.90 moles of aluminum ...

Embodiment 3

[0092] 1) According to the molar ratio is Na 2 O: Al 2 o 3 :SiO2 2 :H 2 O=16:1:15:320 prepares the directing agent, specifically:

[0093] Under the condition that the temperature of the water bath is 34°C, dissolve 0.05 mol of aluminum sulfate and 1.60 mol of sodium hydroxide in 6 mol of deionized water and stir until completely dissolved to obtain the first mixture, and dissolve 0.75 mol of sodium silicate in 6 Stir in 1 mole of deionized water until completely dissolved to obtain the second mixture, mix the first mixture and the second mixture evenly, add 4 moles of deionized water, stir for 30 minutes, seal and age for a day and night to obtain the directing agent (the directing agent is colloidal) ;

[0094] 2) Prepare mother liquor

[0095] At a water bath temperature of 50°C, dissolve 6.4 moles of sodium hydroxide, 0.86 moles of aluminum sulfate and 0.17 moles of nickel nitrate in 84 moles of deionized water and stir until fully dissolved to obtain a third mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| External specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com