A kind of preparation method of mos2 micro-nano ball with hierarchical structure

A technology of micro-nano spheres and hierarchical structure is applied in the field of preparation of MoS2 micro-nano spheres, which can solve the problems of difficult control of particle shape and high energy consumption, and achieve the effects of low cost, large amount of products and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] MoS with hierarchical structure 2 Preparation and characterization of micro-nanospheres:

[0020] The preparation method mainly includes two processes of preparation of reaction precursor liquid and hydrothermal reaction, and the specific steps are as follows:

[0021] 1) At room temperature, add 3 g of thioacetamide and 0.4 g of sodium molybdate to 100 mL of polyacrylamide (PAM) aqueous solution with a concentration of 0.1 g / L, and stir evenly to obtain a reaction precursor;

[0022] 2) Transfer the reaction precursor solution into the reactor and conduct hydrothermal reaction at 180°C for 24 hours to obtain MoS 2 Micro-nano structured materials.

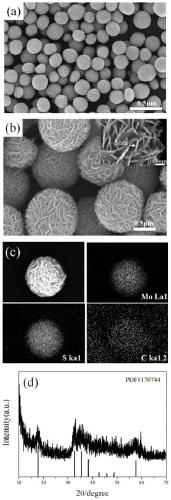

[0023] figure 1 Figure a is the SEM overall morphology of the prepared product molybdenum disulfide, which is the macroscopic distribution of molybdenum disulfide particles, and the obtained MoS 2 Mainly exists in spherical form, the obtained MoS 2 The degree of sphericity is very high, the degree of agglomeration is re...

Embodiment 2

[0025] The effect of different polyacrylamide dosage on MoS 2 Influence of Particle Morphology:

[0026] In this embodiment, two groups of experiments were adopted, respectively without adding polyacrylamide (PAM) and adding excessive polyacrylamide (PAM) (concentration: 3 g / L), and other conditions were the same as in Example 1.

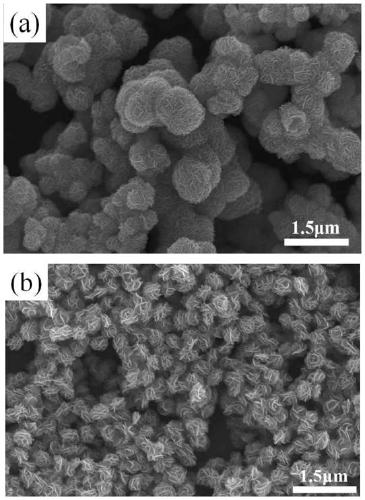

[0027] figure 2 a represents the form of the molybdenum disulfide product obtained without adding polyacrylamide (PAM), the particle size is irregular, the shape is different, and the agglomeration phenomenon is very serious. After adding excess polyacrylamide (PAM) (concentration is 3g / L), if figure 2 b. Although spherical molybdenum disulfide can be obtained, the morphology of the obtained product is not very regular, which is not as expected. When the amount of polyacrylamide (PAM) is 0.01-0.3g / 100mL, the morphology of the obtained molybdenum disulfide is better.

[0028] Based on the above experimental results, it can be considered that Mo...

Embodiment 3

[0032] Effect of different reaction times on MoS 2 Particle shape and size effects:

[0033] This embodiment adopts three groups of experiments, and the hydrothermal reaction time is 12h, 24h, 48h respectively, and other conditions are the same as embodiment 1.

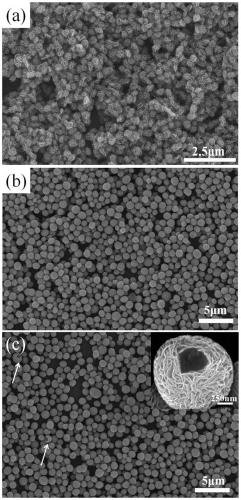

[0034] image 3 The main explanation is to change the reaction time to explore the morphology characteristics of molybdenum disulfide. The concentration of polyacrylamide (PAM) used was 0.01 g / 100 mL. image 3 a is the SEM image of the product obtained with a reaction time of 12 hours. It can be seen from the figure that although the molybdenum disulfide is spherical, it has agglomeration. image 3 b is the SEM picture of the product obtained with a reaction time of 24 hours. The particle size of the obtained product is relatively uniform, and there is no agglomeration phenomenon, and the effect is the best. When the reaction is 48h, such as image 3c. At this time, the shape of molybdenum disulfide is still sphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com