Method for rapidly removing organic pollutants in coal gas wastewater

A technology of organic pollutants and coal-to-gas, applied in the fields of water pollutants, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of complex equipment, high operating costs, foam problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The mixed salt-loving / halo-tolerant flora used in Example 1 was derived from the high-salt brine in the crystallization pool of the Tanggu Salt Field in Binhai New Area, Tianjin. The collection steps of the flora are as follows:

[0019] (1) Bacteria enrichment: Collect an appropriate amount of high-salt brine and inoculate it into 2216E medium with a NaCl concentration of 300g / L, culture at a constant temperature and shake at 37°C for 7 days, and enrich to obtain mixed halophilic / halal-tolerant flora 1.

[0020] (2) High-salt osmotic-resistant culture: Inoculate the mixed flora 1 in 2216E medium with a NaCl concentration of 100-250g / L to continue the osmotic-resistant culture, and obtain a mixed flora of salt-loving / halal-tolerant after 7 days of constant temperature shaking culture at 37°C 2.

[0021] The NaCl concentration of the medium in this step is lower than that of step (1), the purpose is to further enrich and obtain a mixed flora with a faster growth rate, a...

Embodiment 2

[0031] The pure strains of halophilic / halophilic bacteria selected in Example 2 were derived from the high-salt brine in the salt pond of Daqing River Salt Field in Changlu, Hangu, Tianjin. The specific isolation and purification steps of the strain are as follows:

[0032] (1) The collected high-salt brine was used to carry out the enrichment of the bacterial flora and the high-salt osmotic culture, the method was exactly the same as that of Example 1, and the mixed bacterial flora 3 of the halophilic / halophilic and tolerant was obtained through enrichment and culture.

[0033] (2) Isolation of pure bacterial strains: Take 1 mL of the bacterial solution of mixed flora 3, dilute it 10, 100, 500, 1000, 2000 times respectively, and spread it on a 2216E solid plate with a NaCl concentration of 15%, seal the plate and place it upside down After culturing in a 37°C incubator for several days, select a plate with uniform distribution of colonies, pick a single colony and place it in...

Embodiment 3

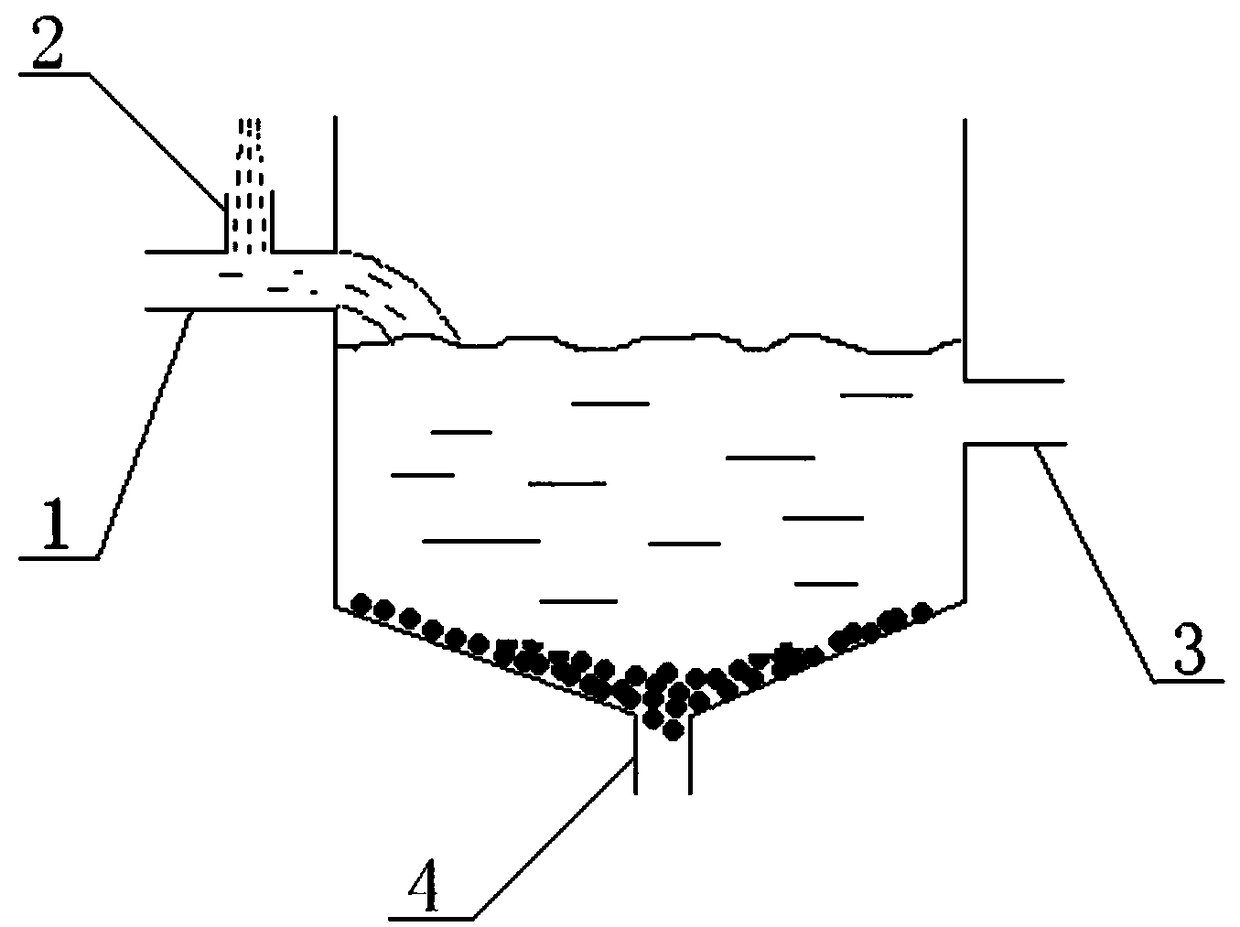

[0046] Use strain 2 as bacterial agent to pretreat wastewater, mainly including dephenolization and oil removal (that is, removal of organic pollutants such as aromatic compounds, heterocyclic compounds, and petroleum hydrocarbons in water). Strain 1 was subjected to high-salt osmotic culture for a period of time before being released, and the method was the same as in Example 2. Pretreatment takes place in sedimentation tanks. Such as image 3 As shown, when the wastewater enters the sedimentation tank from the water inlet 1, the bacterial agent is continuously input from the branch feeding port 2 on the side of the water inlet 1 (it can also be added directly from the top of the pool through the sprayer), and the amount of the bacterial agent added is 8g. / L, after the pool is filled with water, let it stand for 20-40 minutes. After the sedimentation is complete, the treated wastewater is discharged from the water outlet 3, and the sediment is discharged from the mud discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com