Glass having pure glass phase, preparation method and uses thereof

A glass, glass powder technology, applied in the field of biomaterials and dental restoration materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

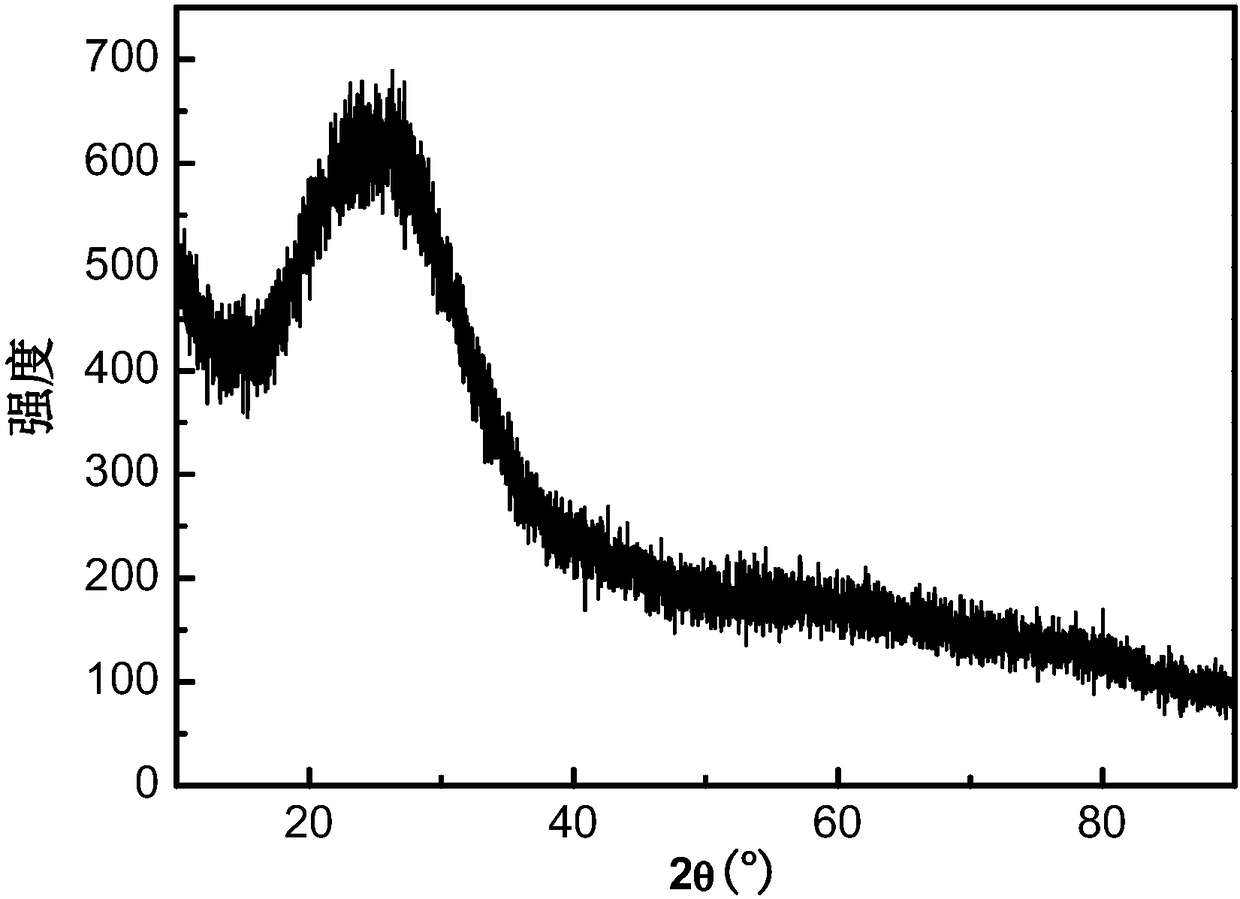

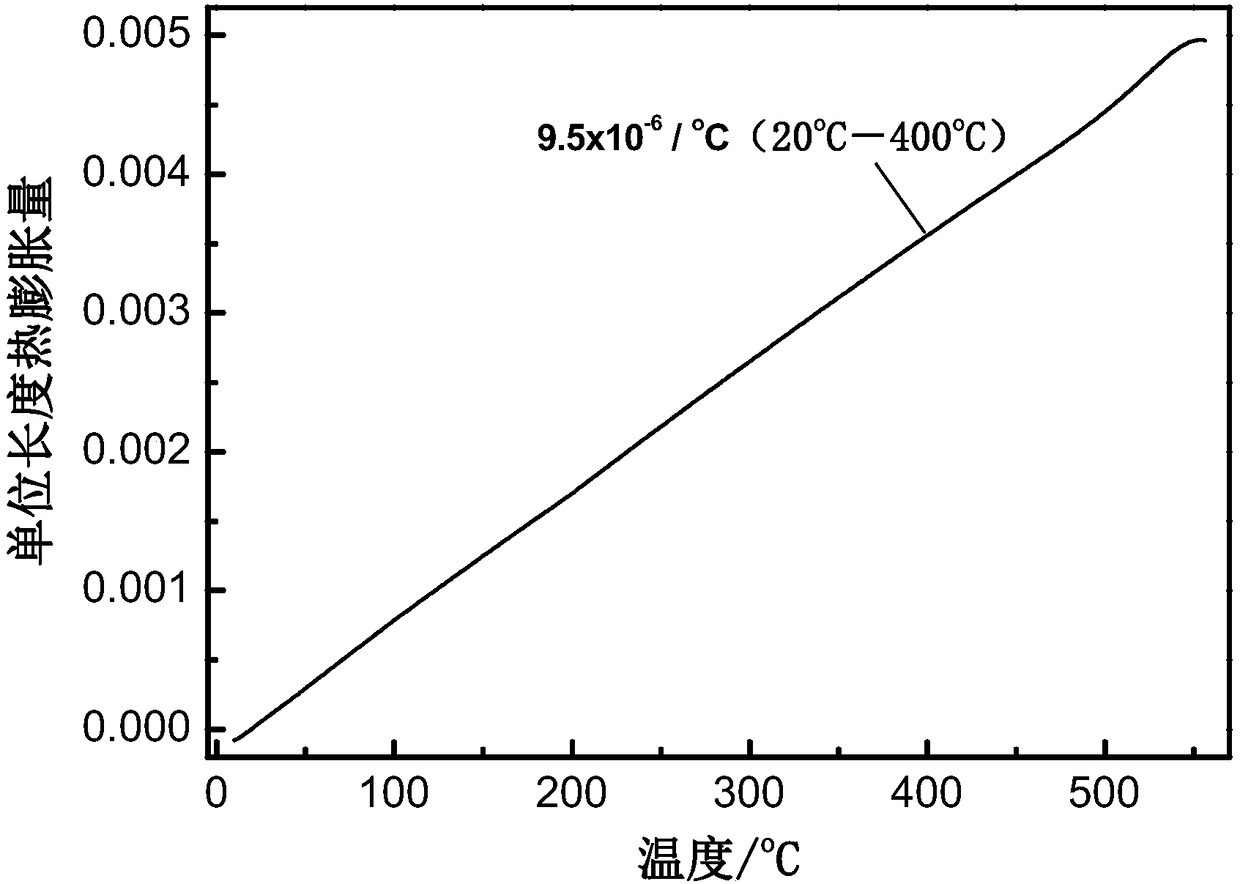

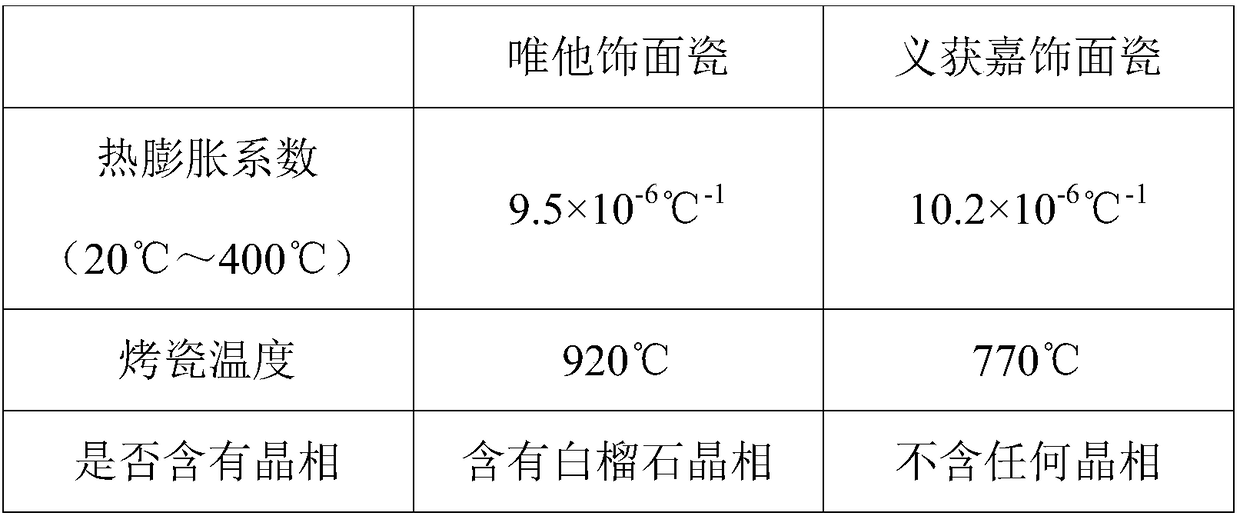

[0070] According to the weight percentage of each component of glass described in each embodiment listed in Table 2, take by weighing analytically pure SiO 2 、Al 2 o 3 、K 2CO 3 、Na 2 CO 3 and optional additive raw materials, after being fully mixed with a planetary ball mill, take out and dry; put the dried powder in a platinum alloy crucible, place it in a box-type resistance furnace, and raise the temperature to 1400 °C under an air atmosphere ℃~1700℃, constant temperature for 1h~5h, melting to obtain glass, that is, decorative porcelain glass, and then pouring water quenching at 1400℃~1600℃ to obtain glass blocks. Then, the glass block is ball milled and pulverized under the condition of 200r / min~400r / min, every 5 minutes of ball milling, and a 300-mesh standard sieve is used to sieve once, and the sieve through the 300-mesh standard sieve is the glass powder, that is, the decoration Face porcelain glass powder.

[0071] In the embodiments of the present invention, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com