A 690mpa grade low carbon medium manganese high strength medium and heavy plate

A high-strength, thick plate technology, applied in the field of medium and thick plate manufacturing, can solve the problem of high alloy cost, achieve the effect of simple operation, excellent performance and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A 690MPa grade low-carbon medium-manganese high-strength medium-thick steel plate with a thickness of 20mm, the chemical composition of which is: C: 0.09%, Mn: 4.97%, Si: 0.20%, S: 0.006%, P: 0.008% , Al: 0.022%, Cu: 0.15%, Ni: 0.26%, Mo: 0.16%, Cr: 0.40%, the balance is Fe and other inevitable impurities; the structure is lath martensite + film-like retained austenite body, the retained austenite volume fraction is 4.9%.

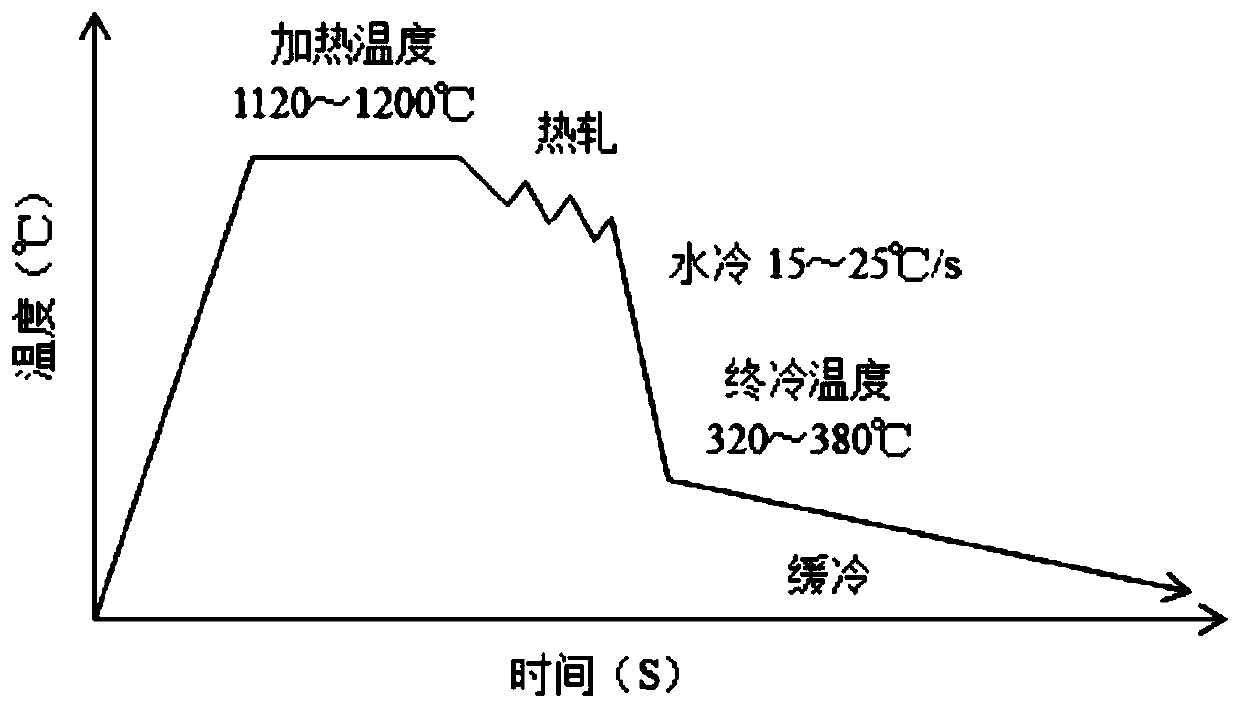

[0032] Its preparation method is as follows:

[0033] The continuous casting slab with a thickness of 230mm of the above components was heated to 1120°C with the furnace and held for 2 hours, and then rolled into a 20mm thick steel plate by one-stage rolling. The starting rolling temperature and finishing rolling temperature were 1050°C and 880°C respectively. ℃, a total of 11 rolling passes, the reduction rate of a single pass is controlled at 10%, and the total reduction rate is 91.30%.

[0034] After the final rolling, the steel plate is water-coo...

Embodiment 2

[0037] A 690MPa grade low-carbon medium-manganese high-strength medium-thick steel plate with a thickness of 80mm, the chemical composition of which is: C: 0.04%, Mn: 5.45%, Si: 0.20%, S: 0.0012%, P: 0.009% , Al: 0.023%, Cu: 0.12%, Ni: 0.21%, Mo: 0.20%, Cr: 0.39%, the balance is Fe and other inevitable impurities; the structure is lath martensite + film-like retained austenite body, the volume fraction of retained austenite is 6.8%.

[0038] Its preparation method is as follows:

[0039] The continuous casting slab with a thickness of 320mm of the above components was heated to 1150°C with the furnace and held for 3 hours, and then rolled into a steel plate with a thickness of 80mm after one-stage rolling. The starting and finishing temperatures were 1020°C and 910°C respectively. ℃, a total of 7 rolling passes, the single-pass reduction rate is controlled at 11%, and the total reduction rate is 75%.

[0040] After final rolling, the steel plate is water-cooled to 380°C at a...

Embodiment 3

[0043] A 690MPa-grade low-carbon medium-manganese high-strength medium-thick steel plate with a thickness of 50mm, the chemical composition of which is: C: 0.06%, Mn: 5.37%, Si: 0.19%, S: 0.009%, P: 0.004% , Al: 0.01%, Cu: 0.31%, Ni: 0.32%, Mo: 0.23%, Cr: 0.42%, the balance is Fe and other unavoidable impurities; the structure is lath martensite + film-like carbon-rich residue Austenite, the volume fraction of retained austenite is 5.45%.

[0044] Its preparation method is as follows: the continuous casting slab with the thickness of 230 mm of the above components is heated to 1200 ° C with the furnace and kept for 2 hours, and then it is rolled into a 50 mm thick steel plate by one-stage rolling. The starting rolling temperature and finishing rolling temperature are respectively 1080 ° C and 930 ° C, a total of 9 rolling passes, the total reduction rate of 78.26%.

[0045] After final rolling, the steel plate was water-cooled to 350 °C at a cooling rate of 20 °C / s, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com