A construction method for deep and large vertical shafts in water-rich magmatic rock areas

A construction method and magmatic rock technology, applied in shaft equipment, wellbore lining, well sinking, etc., can solve the problems of large investment in wellbore freezing method, difficult to guarantee drilling accuracy, difficult cracks to be exposed and plugged, etc. Construction safety, reducing the risk of wellbore inrush water, and relieving the effect of pumping and drainage pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

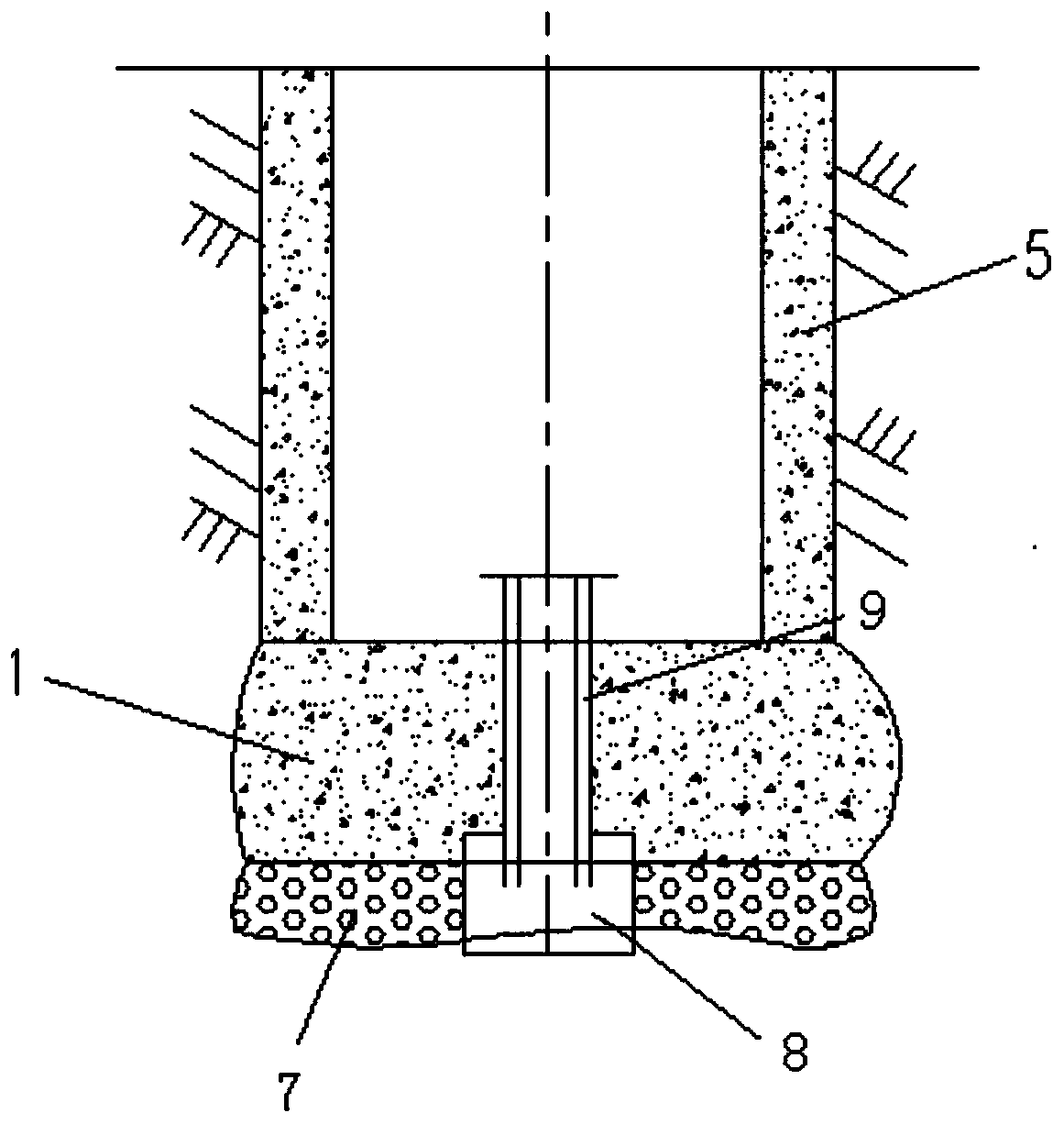

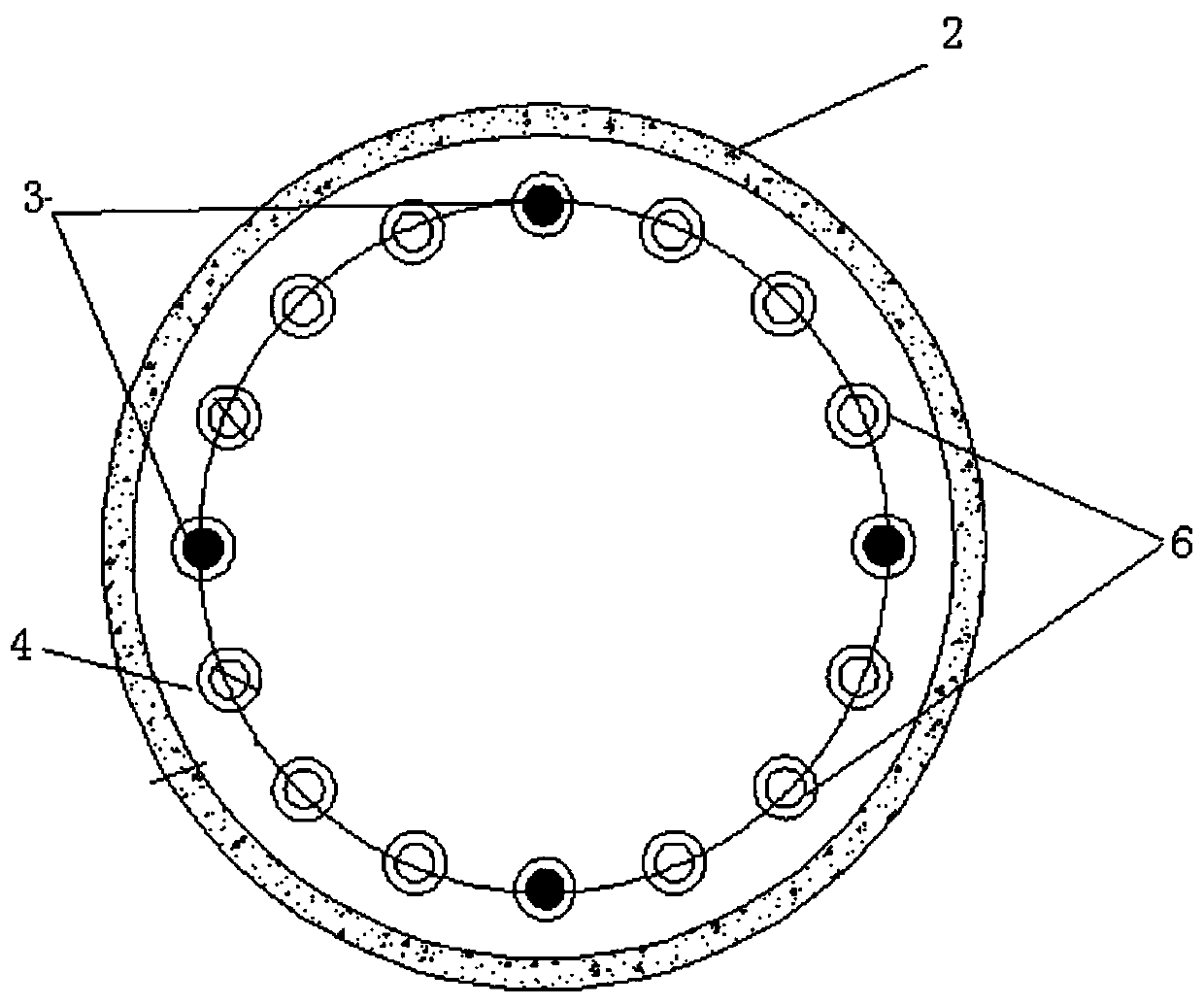

[0038] Example 1: Newly build the Dali-Ruili Railway, the Baoshan-Ruili section Gaoligongshan Tunnel, with a total length of 34538m, is the longest railway tunnel in Asia, and the maximum buried depth of the tunnel is about 1155m. The tunnel is equipped with auxiliary tunnels of "1 through horizontal guide + 1 inclined shaft + 2 vertical shafts". Among them, the No. 1 vertical shaft adopts main and auxiliary shafts. The shaft of the main shaft is 6m and the depth is 762.59m. Double as a safety exit;

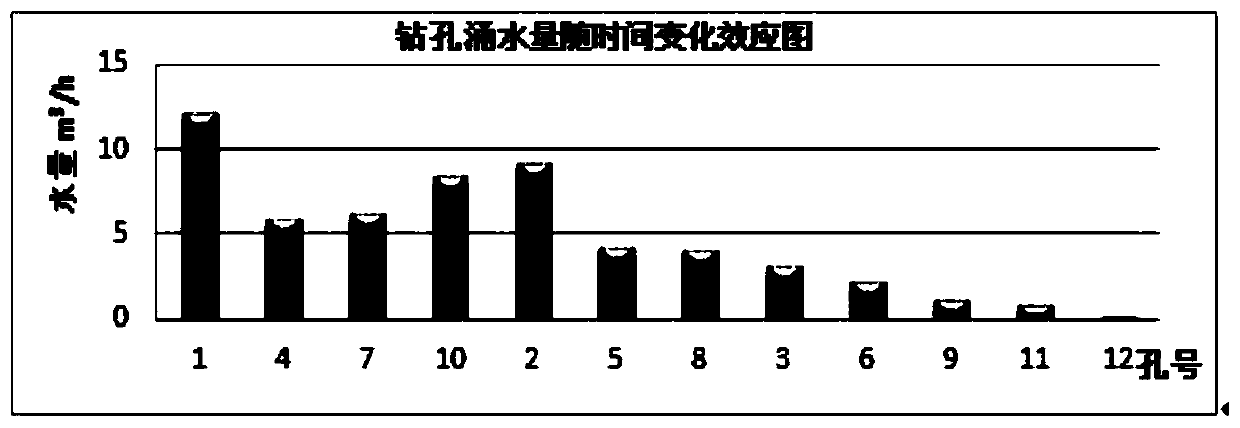

[0039] The wellhead of Shaft No. 1 is about 1.3km away from Baoshanduan Nujiang Fault (F1-1) and about 1.2km away from Ruiliduan Zhenan Fault (F4-2). Affected by the two faults, the surrounding rock of the wellbore is broken, fractures are developed and water-rich , The trend of surrounding rock fissures, the connection is irregular, the direction is mostly high-angle fissures, and the water replenishment channels communicating with the surrounding and upper parts are unimpeded....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com