Method for testing high-pressure gas purity

A purity inspection, high-pressure gas technology, used in the analysis of gas mixtures, using liquid/vacuum for liquid tightness measurement, and testing fluid tightness by detecting dimensional changes of the structural components to be tested. Pollution, quality lower than the index requirements and other problems, to achieve the effect of improving accuracy, reducing labor costs, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is further described in detail through specific implementation methods:

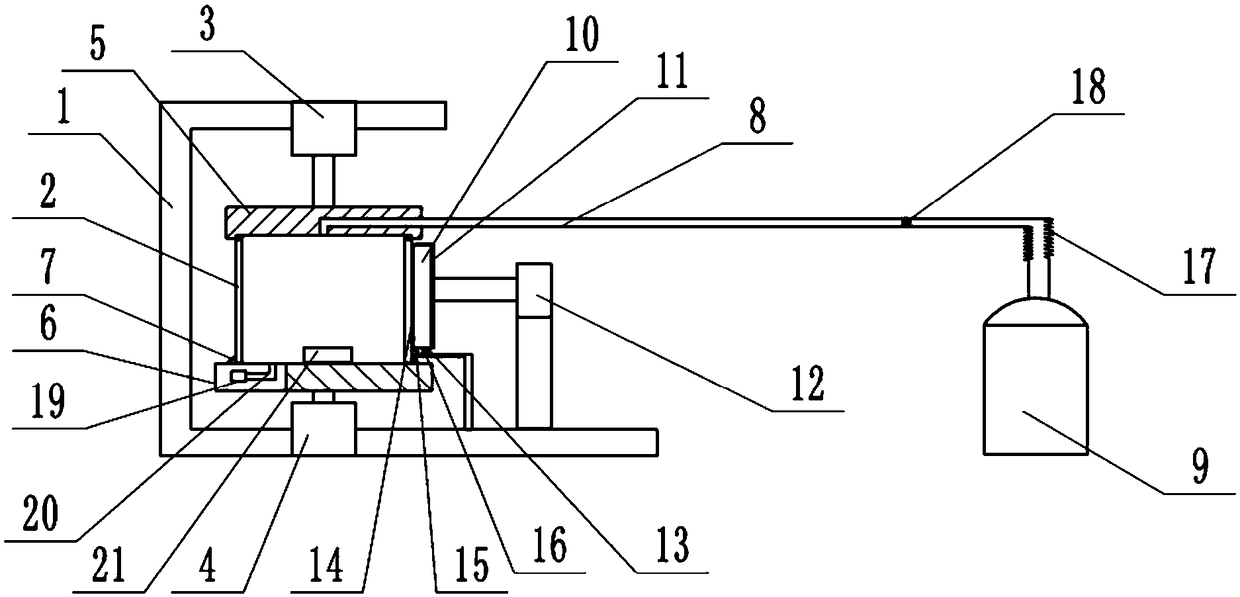

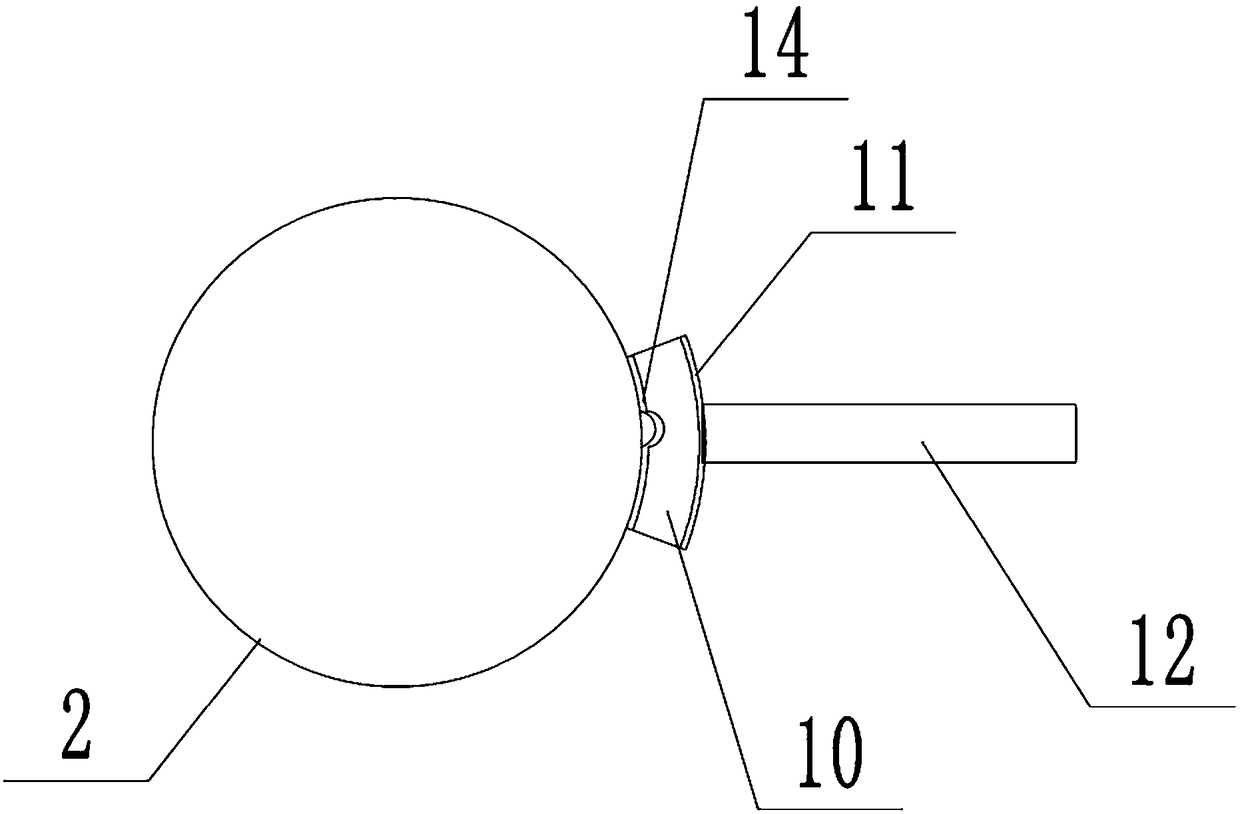

[0030] The reference signs in the drawings of the description include: frame 1, lining 2, compression cylinder 3, motor 4, upper sealing cover 5, lower sealing cover 6, claw 7, air intake pipe 8, high-pressure container 9, arc Shaped airbag 10, curved plate 11, electric push rod 12, touch rod 13, reflective layer 14, infrared distance measuring sensor 15, touch switch 16, telescopic tube 17, pressure control valve 18, vacuum pump 19, air extraction pipe 20 , Gas purity detector 21.

[0031] Such as figure 1 and figure 2 As shown, the embodiment of the present invention uses a detection device, including a frame 1 and a liner 2 with upper and lower openings, and also includes:

[0032] The sealing mechanism includes a pressing cylinder 3 arranged on the top of the frame 1, and a motor 4 arranged at the bottom of the frame 1. The output end of the pressing cylinder 3 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com