Active discharge method for motor controller

A motor controller and active technology, applied in the direction of motor control, motor, electric vehicle, etc., can solve the problems of high hardware design cost, increase of peripheral circuits, etc., to save PCB area and avoid IGBT damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

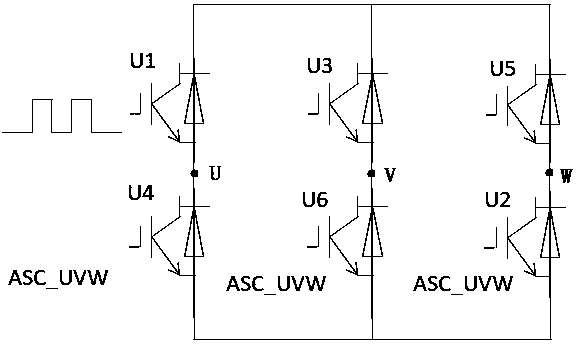

[0016] In the active discharge method of the motor controller of the present invention, the motor controller is powered by the DC bus through the bus capacitor and the inverter connection, such as figure 1 As shown, the inverter includes U, V, and W three-phase bridge arms composed of six IGBTs (U1-U6), and each phase bridge arm includes an upper bridge arm and a lower bridge arm connected in series.

[0017] The active discharge function is turned on, and the high-level drive signal ASC_UVW is used to control the IGBT U4, U6, and U2 of the lower three bridge arms of the inverter to be turned on at the same time, and the motor winding is short-circuited through the lower three bridge arms, that is, the lower ASC; combined with the motor controller Structural water channel and heat dissipation design, the U-phase upper bridge arm is close to the water channel, and the heat dissipation is better; the U-phase upper bridge arm is selected as the active discharge bridge arm, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com