Speaker diaphragm and manufacture method thereof

A loudspeaker and composite layer technology, applied in the field of loudspeakers, can solve problems such as the inability to adapt to the actual application of the working frequency, the asynchronous split vibration of the composite diaphragm, the large difference in thermal expansion and cold contraction characteristics, etc., to avoid thermal expansion separation, good flame retardant The effect of improving the stability and transient characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

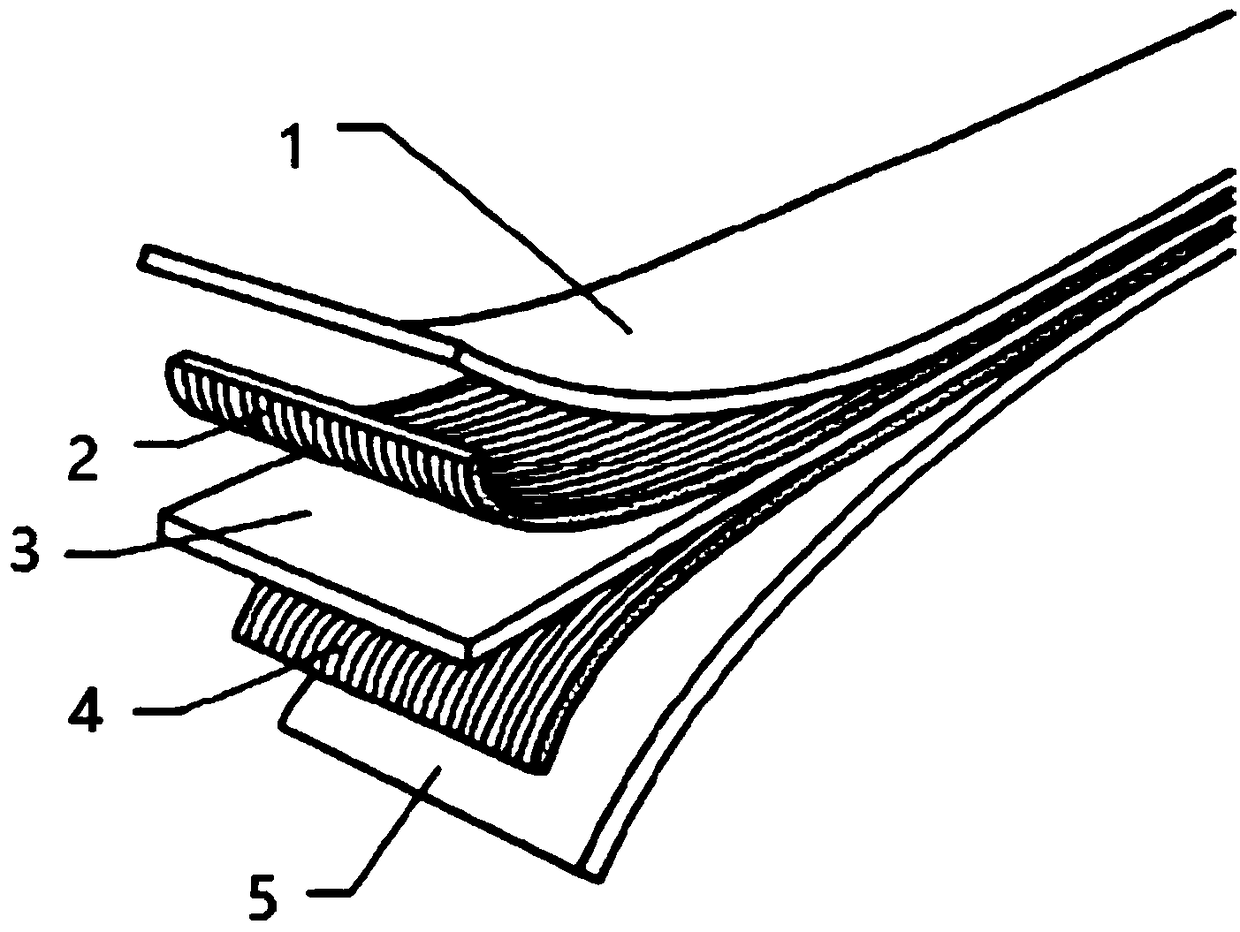

[0037] Below in conjunction with accompanying drawing, the present invention will be further described.

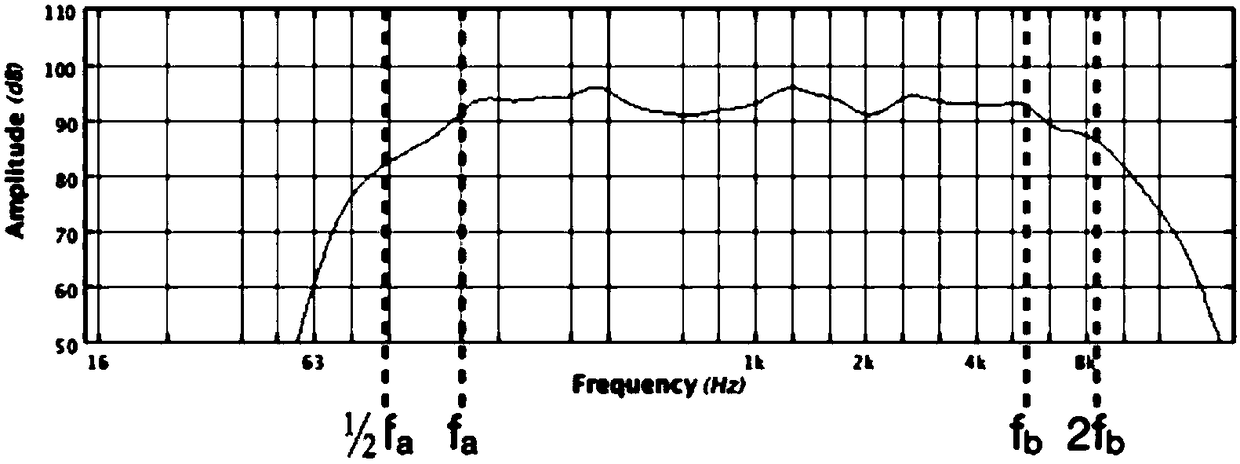

[0038] Such as figure 2 As shown, a loudspeaker diaphragm includes Kevlar fiber woven cloth 1, a first composite layer 2, a low-density PMI layer 3, a second composite layer 4 and a high-density PMI layer 5 from the surface layer to the bottom layer, and the first composite layer 2 It is used for compounding Kevlar fiber woven cloth 1 and low-density PMI layer 3 , and the second composite layer 4 is used for compounding low-density PMI layer 3 and high-density PMI layer 5 . Wherein the Kevlar fiber woven cloth 1 is used as the surface layer, the low-density PMI layer 3 is used as the damping layer, and the high-density PMI layer 5 is used as the strengthening layer.

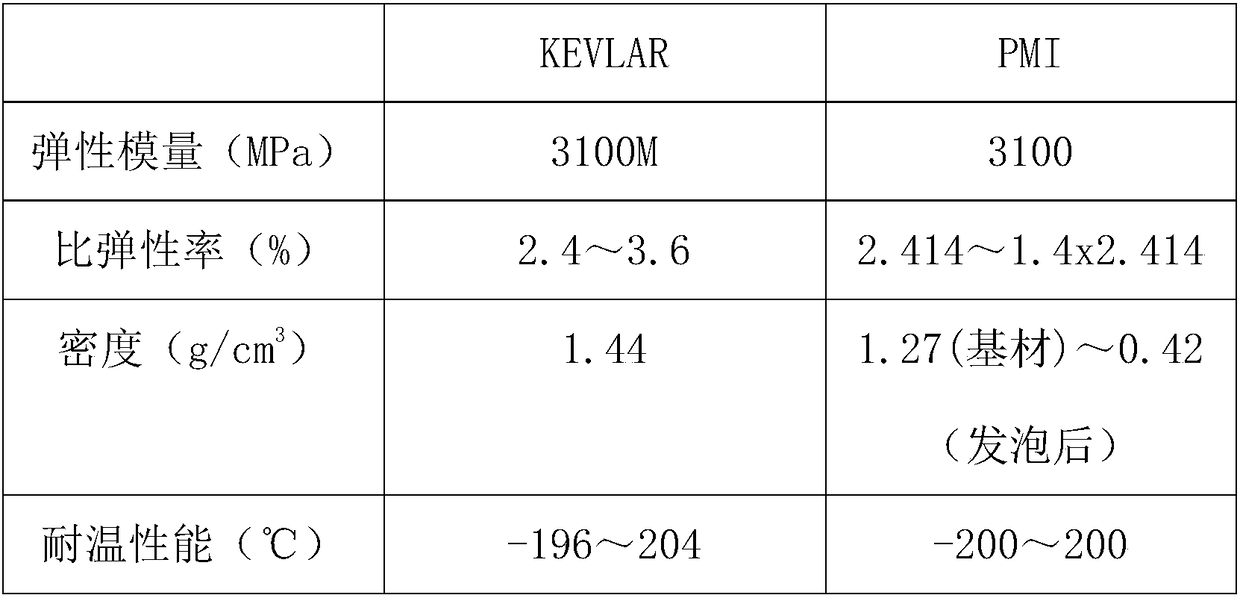

[0039] The base material selected by the diaphragm of the present invention is: braided KEVLAR fiber and PMI foam material. The reason why these two materials are selected is that they have very close physi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com