Non-scaling-powder pulse ultrasound low-temperature brazing method for copper-based materials

A technology of pulsed ultrasonic and brazing method, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high pressure required for ultrasonic, high welding temperature, and industrialization of high-frequency data line welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

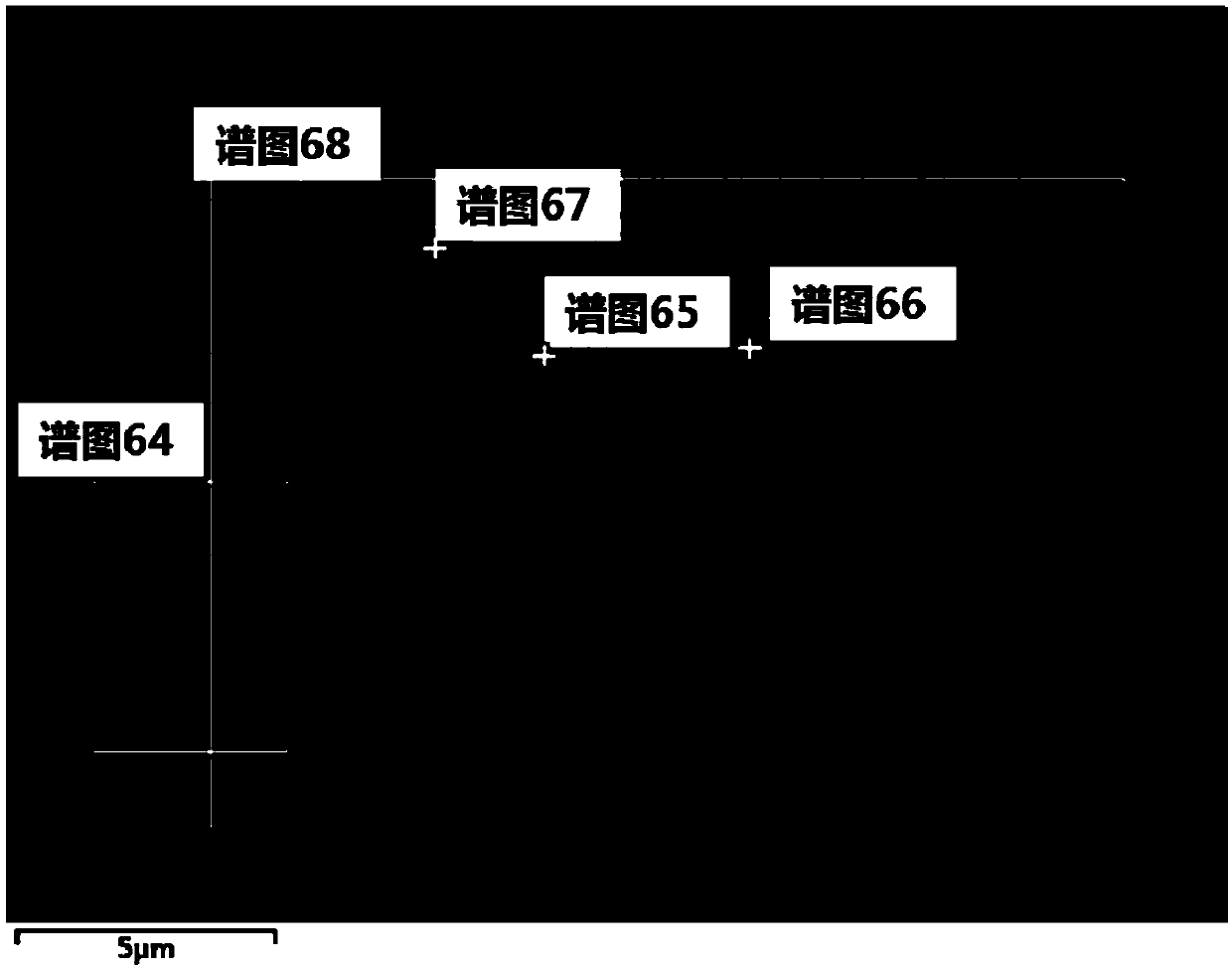

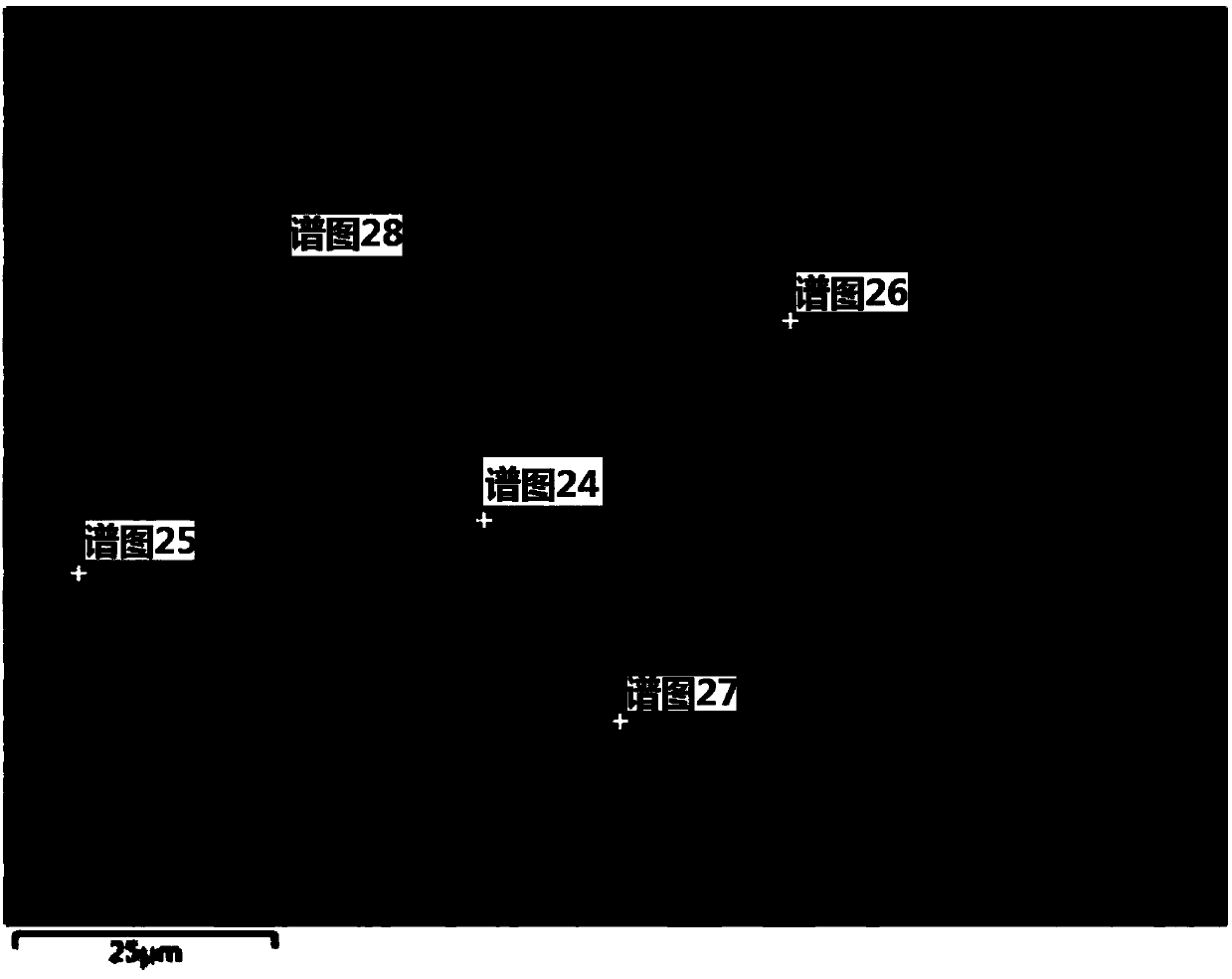

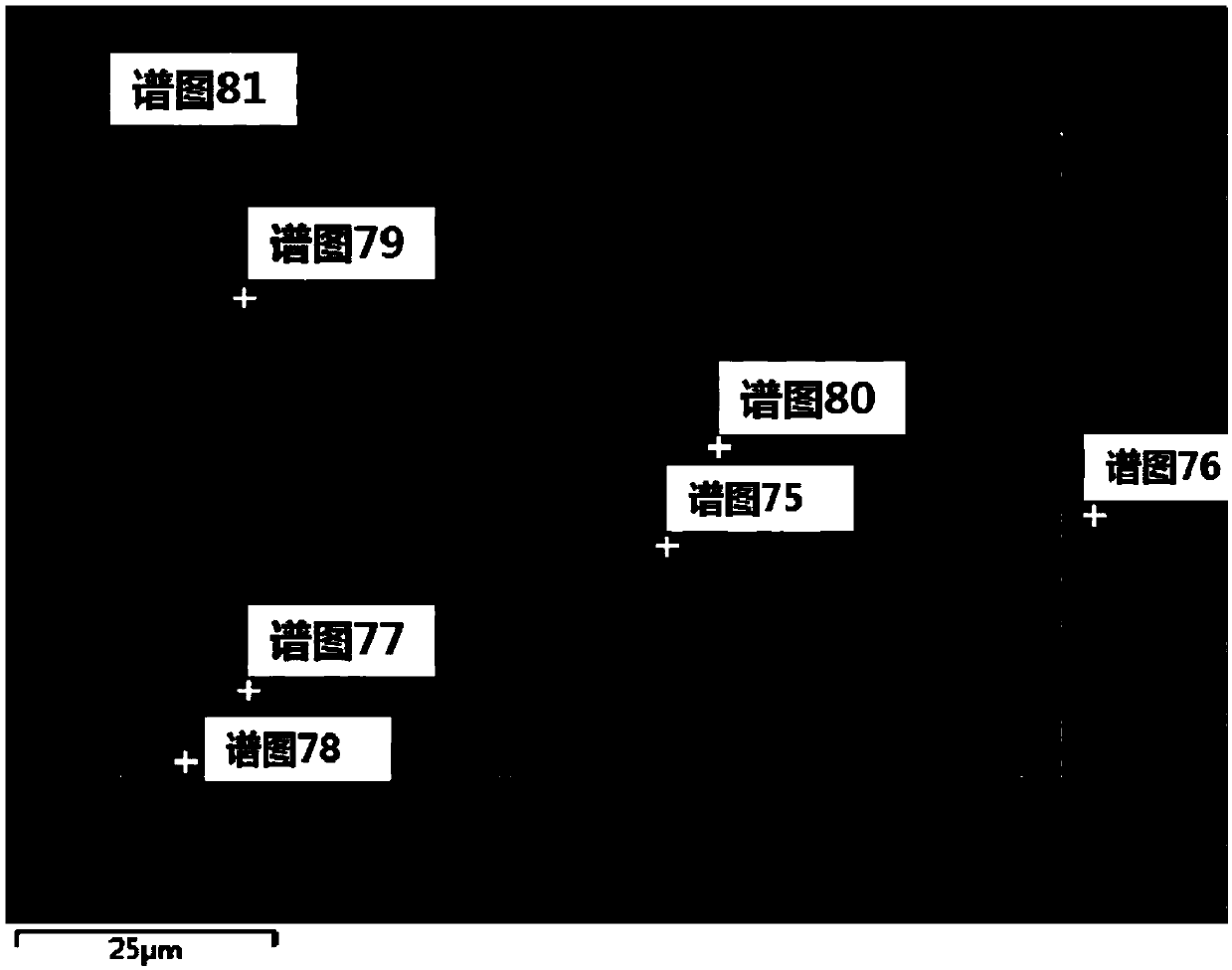

Image

Examples

Embodiment 1

[0149] A flux-free pulse ultrasonic low-temperature brazing method for copper-based materials, comprising the steps of:

[0150] Step S0: Ultrasonic solder dipping step, pre-impregnating the surface of the welding part of the copper-based base material with alloy solder by the ultrasonic solder dipping method, and then forming the assembly to be soldered;

[0151] Specifically, the ultrasonic brazing method is to immerse the welding part of the copper-based base metal in the alloy solder tank for 1 to 5 seconds and then remove the alloy solder tank, and at least during the soaking process, the liquid in the alloy solder tank Apply the second ultrasonic wave to the alloy solder or apply the second ultrasonic wave to the copper-based base material, and control the frequency of the second ultrasonic wave at 15-100KHz and the power at 100-500w, so that a layer of fine alloy is attached to the surface of the welding part Solder layer; preferably, the frequency of the second ultraso...

Embodiment 2

[0171] A flux-free pulse ultrasonic low-temperature brazing method for a copper wire and a circuit copper substrate, comprising the following steps:

[0172] Step S1 : stripping off the sheath, peeling off the sheath at the end of the copper wire, exposing the outer end of the copper wire to form a copper wire welding portion.

[0173] Specifically, an ultrasonic knife is used to strip the outer skin of the end of the copper wire; the sonoplastic effect of the ultrasonic wave is used to directly apply ultrasonic waves to the core stripping knife to improve bad phenomena such as mechanical knife stripping the core and breaking the copper wire.

[0174]Step S2: Ultrasonic brazing, immersing the soldered part of the copper wire and / or the copper circuit board in the alloy solder tank for 1 to 5 seconds before removing the alloy solder tank, and at least during the soaking process, the The second ultrasonic wave is applied to the liquid alloy solder, or the second ultrasonic wave ...

Embodiment 3

[0209] The present invention also provides a flux-free pulse ultrasonic low-temperature brazing method for copper wires and copper terminals in a high-frequency data line interface, which includes the following steps:

[0210] Step S1: stripping off the sheath, stripping off the outer sheath of each copper wire end in the high-frequency data line, so that the outer end of the copper wire is exposed to form a copper wire welding part;

[0211] Preferably, use an ultrasonic knife to peel off the sheath of each copper wire end in the high-frequency data line;

[0212] Step S2: Ultrasonic immersion brazing, immersing the soldered part of the copper wire and / or the copper terminal in the alloy solder tank for 1 to 5 seconds before removing the alloy solder tank, and at least during the soaking process, the Apply a second ultrasonic wave to the liquid alloy solder, or apply a second ultrasonic wave to the copper wire welding part and / or copper terminal, and control the frequency of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com