Ceramic

A ceramic, pedestal technique applied to ceramics. It can solve the problems of low work efficiency, high labor intensity, and low surface finish of ceramics, and achieve the effects of reducing labor intensity, improving work efficiency, and increasing polishing precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

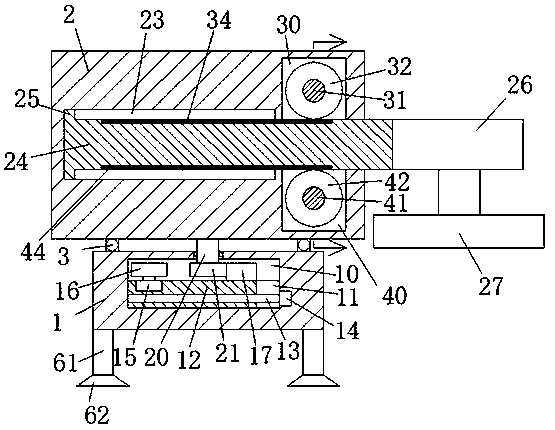

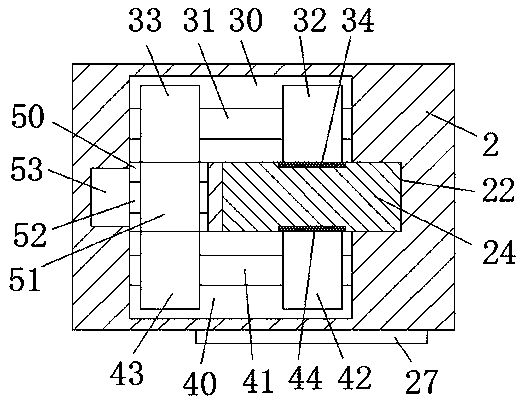

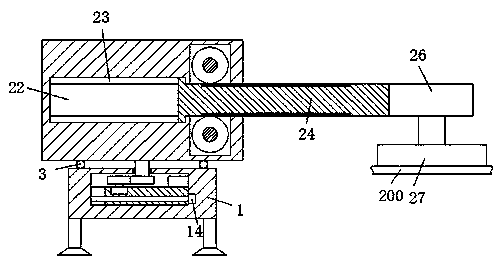

[0018] like Figure 1-Figure 4 As shown, a ceramic of the present invention includes a base 1 and a pedestal 2 that is rotatably arranged on the base through a ring-shaped revolving member 3, and a revolving cavity 10 is provided in the base 1, and the The bottom end wall of the swirl cavity 10 is provided with a left and right elongated control tube sliding groove 11, and the control tube sliding block 12 which can slide left and right is arranged in the control tube sliding groove 11 and slides with the control tube. The block 12 is threaded and connected to the pipe-operating stud 13, the right end of the pipe-operating stud 13 is power-connected with the pipe-operating motor 14, and the center of the bottom end surface of the base frame 2 is fixedly provided with a downward extension penetrating through the base The swivel shaft 20 on the top of the seat 1 and extended to the swirl cavity 10, the swivel shaft 20 is revolvably connected to the top of the base 1, and the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com