Energy-saving and environment-friendly coating production wastewater recycling device

A technology that produces waste water, energy saving and environmental protection. It is used in waste coating treatment, water aeration, sustainable biological treatment, etc. It can solve problems such as untimely and effective removal of sediment and sludge, waste, and energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

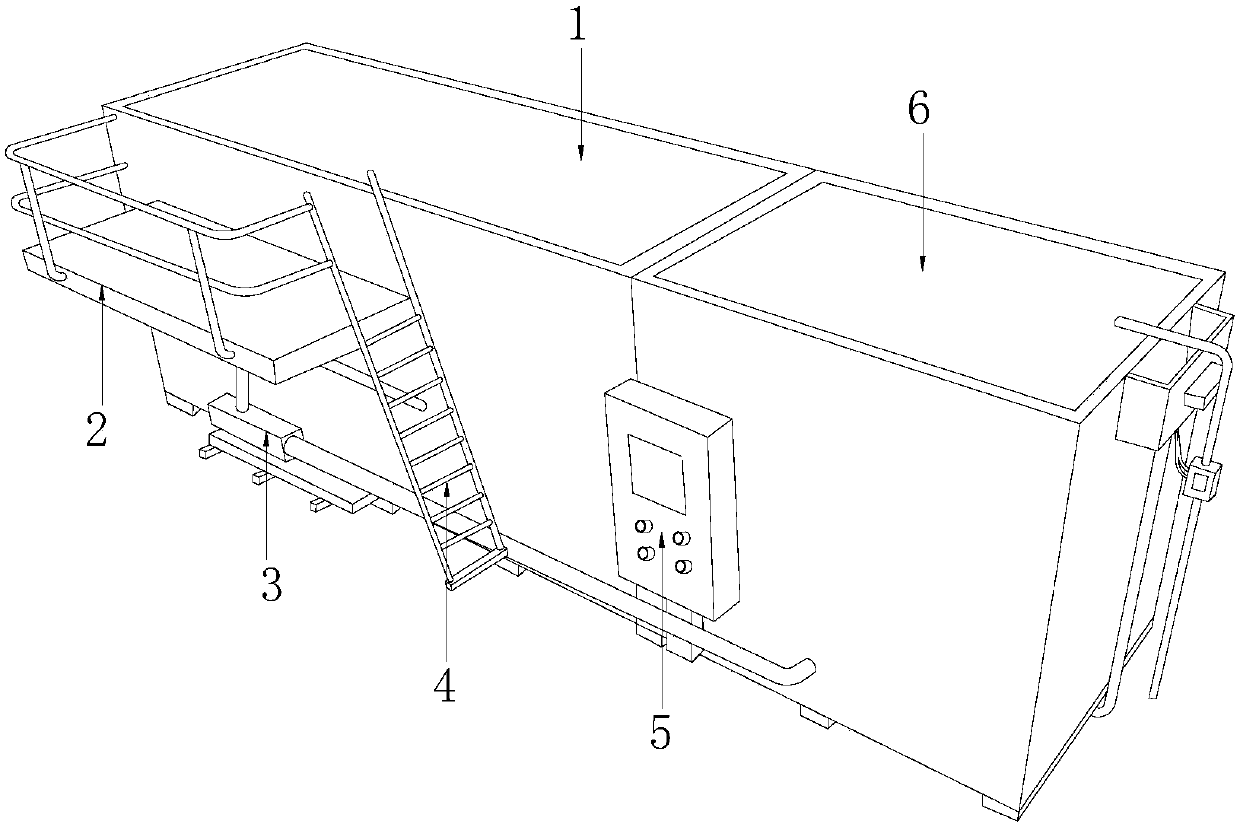

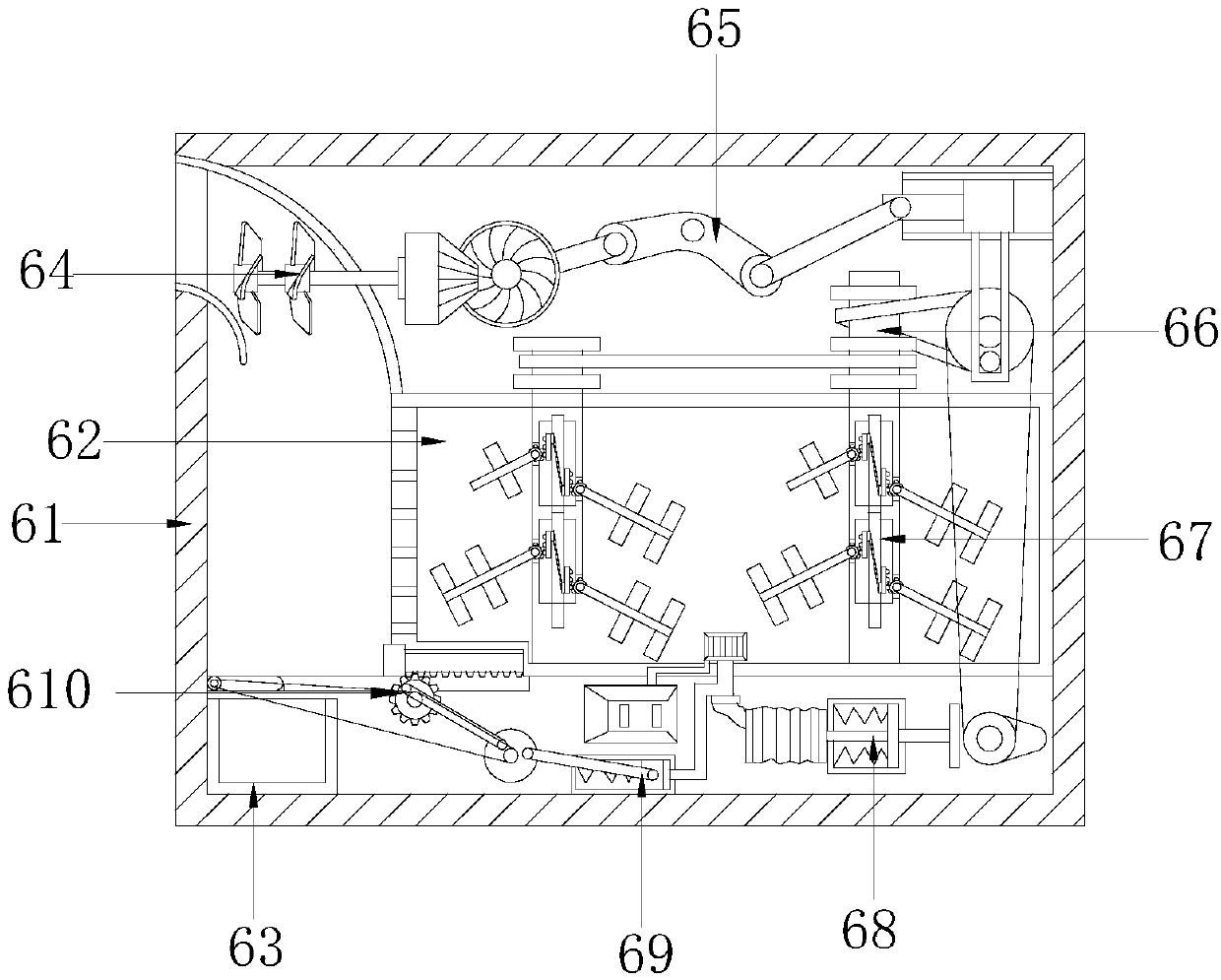

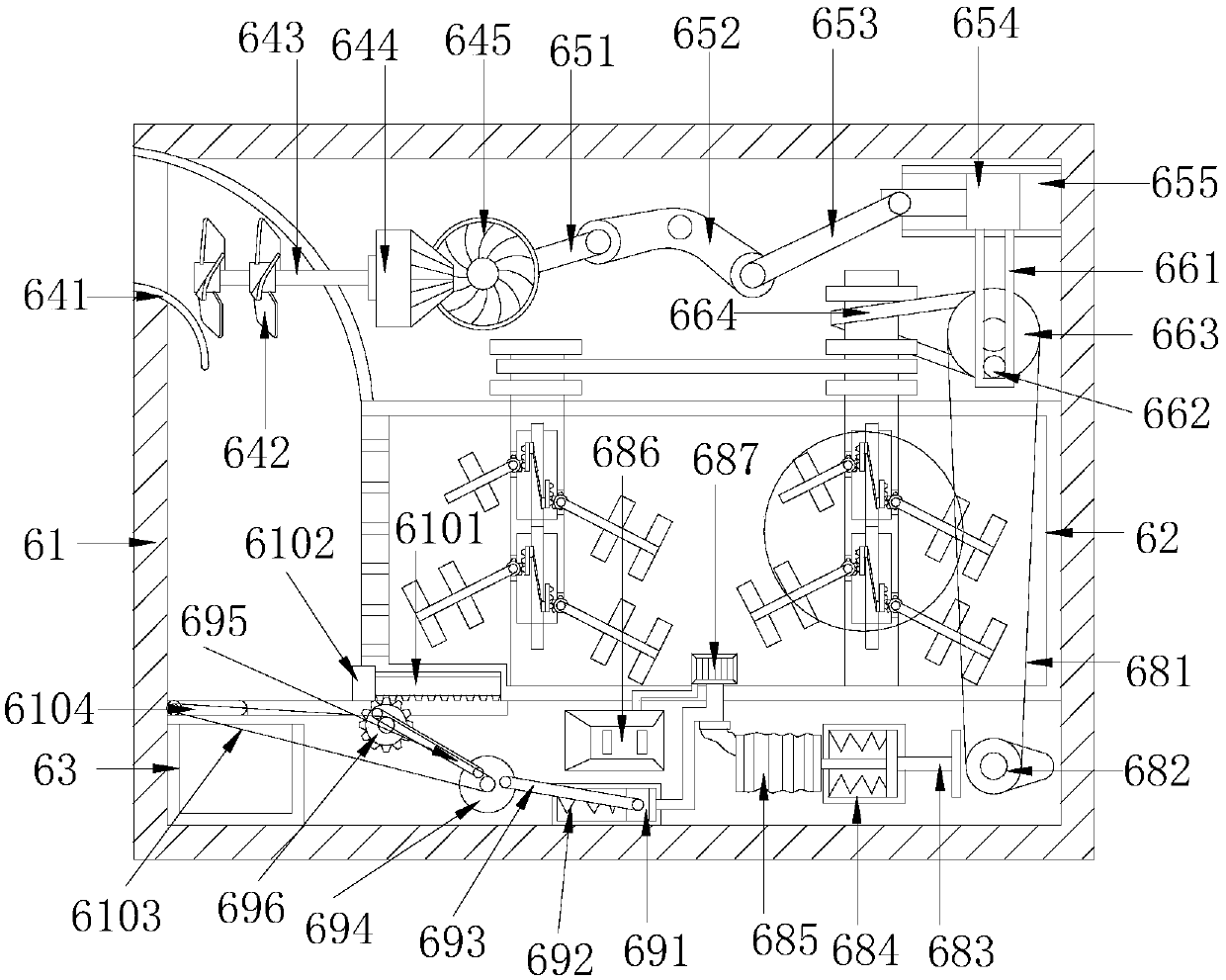

[0026] Such as Figure 1-5 As shown in the figure, the present invention provides a technical solution for energy-saving and environmentally-friendly paint production wastewater recycling equipment:

[0027] An energy-saving and environmentally friendly paint production waste water recycling equipment, its structure includes a paint production body 1, an observation and monitoring platform 2, a circulating pump 3, an escalator 4, an operation control cabinet 5, and a waste water purification treatment recycling device 6, the paint production body The right end face of 1 is connected with the waste water purification treatment recycling device 6, the outer surface of the paint production body 1 is installed with an observation and monitoring platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com