A kind of multifunctional epoxy compound-terminated anti-moisture and heat aging polyester film and its synthesis method

A technology of epoxy compounds and epoxy compounds, applied in the field of polyester synthesis, can solve problems such as performance degradation, and achieve the effects of eliminating reprocessing, high reactivity and reducing carboxyl end groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

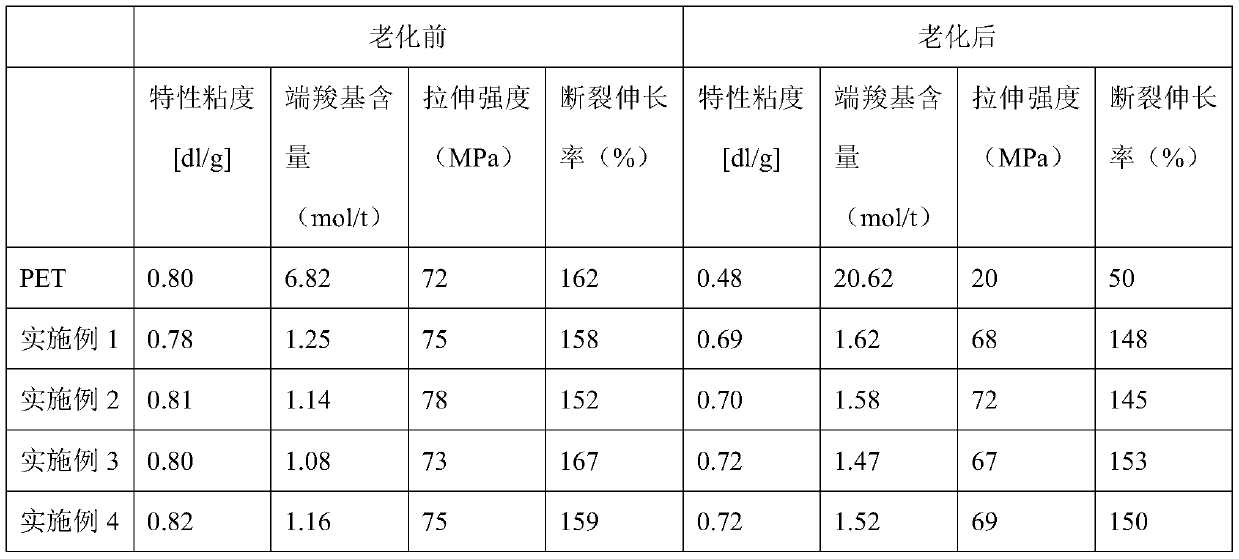

Examples

Embodiment 1

[0022] Synthesis of a Multifunctional Epoxy Compound-terminated Polyester with Moisture and Heat Aging Resistance

[0023] Raw material: 400g of terephthalic acid, 180g of ethylene glycol, 0.16g of antimony ethylene glycol, 0.1g of trimethyl phosphate, 5g of diglycidyl ether (Mn≈130) was added.

[0024] step:

[0025] (1) PET was synthesized in a 2L special polyester experimental reactor. Add all the above-mentioned raw materials into the reaction kettle at one time before the reaction starts, start stirring before adding, the stirring speed is 25Hz / min, slowly put in the raw materials and additives, and stir for 10 minutes. Close the feeding port after feeding. Nitrogen was pumped three times to remove the oxygen in the reaction kettle.

[0026] (2) Feed in nitrogen to raise the pressure in the kettle to 150KPa. After the material is evenly stirred, turn on the electric heater of the reactor to heat the material slowly. The jacket heating temperature is set to 270°C by th...

Embodiment 2

[0032] Synthesis of a Multifunctional Epoxy Compound-terminated Polyester with Moisture and Heat Aging Resistance

[0033] Raw materials: 360g terephthalic acid, 40g isophthalic acid, 224g ethylene glycol, 0.08g antimony ethylene glycol, 0.08g tetrabutyl titanate, 0.1g trimethyl phosphate, add diglycidyl ether (Mn≈130 ) 5g.

[0034] Synthetic steps:

[0035] PET was synthesized in a 2L special polyester experimental reactor. Add all the above-mentioned raw materials into the reaction kettle at one time before the reaction starts, start stirring before adding, the stirring speed is 25Hz / min, slowly put in the raw materials and additives, and stir for 10 minutes. Close the feeding port after feeding. Nitrogen was pumped three times to remove the oxygen in the reaction kettle.

[0036] Nitrogen was introduced to raise the pressure in the kettle to 150KPa. After the material is evenly stirred, turn on the electric heater of the reactor to heat the material slowly. The jacket ...

Embodiment 3

[0043] Synthesis of a Multifunctional Epoxy Compound-terminated Polyester with Moisture and Heat Aging Resistance

[0044] Raw materials: 400g of terephthalic acid, 180g of ethylene glycol, 0.08g of antimony ethylene glycol, 0.08g of tetrabutyl titanate, 0.1g of trimethyl phosphate, and 15g of polypropylene glycol diglycidyl ether (Mn≈380).

[0045] Synthetic steps:

[0046] PET was synthesized in a 2L special polyester experimental reactor. Add all the above-mentioned raw materials into the reaction kettle at one time before the reaction starts, start stirring before adding, the stirring speed is 25Hz / min, slowly put in the raw materials and additives, and stir for 10 minutes. Close the feeding port after feeding. Nitrogen was pumped three times to remove the oxygen in the reaction kettle.

[0047] Nitrogen was introduced to raise the pressure in the kettle to 150KPa. After the material is evenly stirred, turn on the electric heater of the reactor to heat the material slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com