Cotton fluffer

A technology of a spring flower machine and a main motor, which is applied to the fiber cleaning machine, cleaning with toothed tools, etc., can solve the problems of health hazards of workers, easy jamming of the licker-in, affecting the working environment, etc., and achieve a good working environment. , the effect of smooth decomposition, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

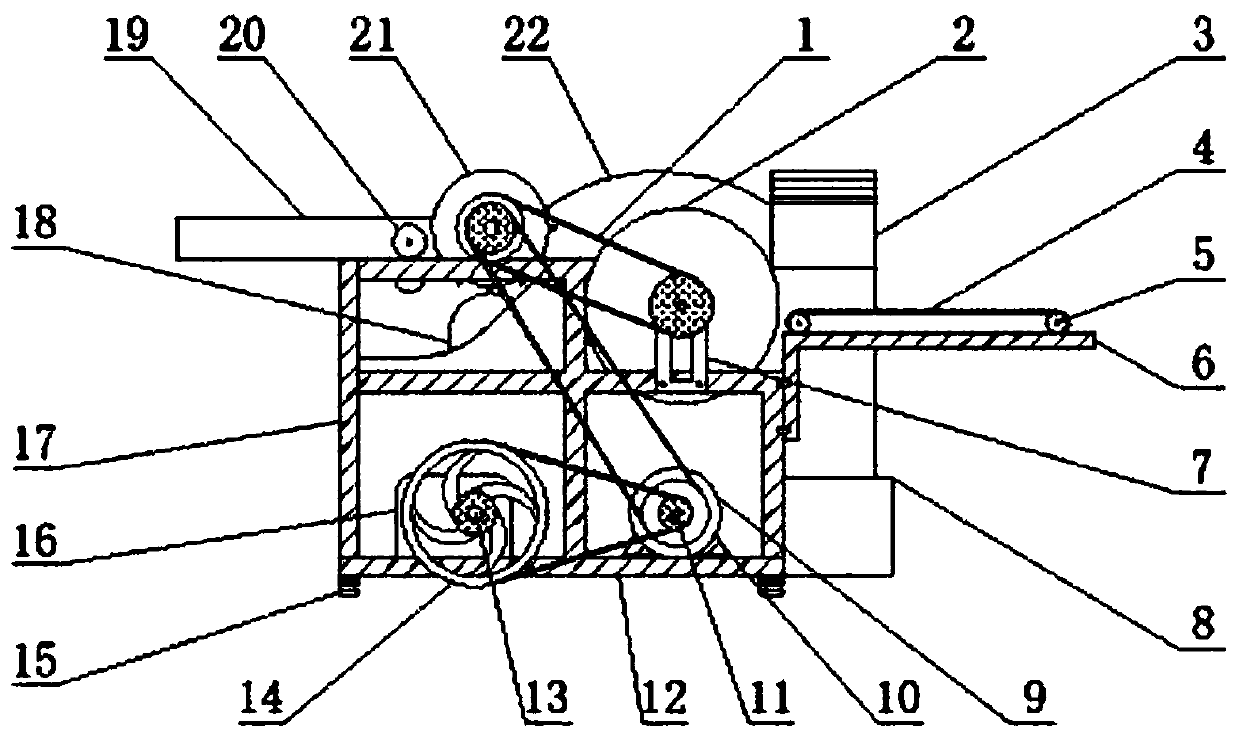

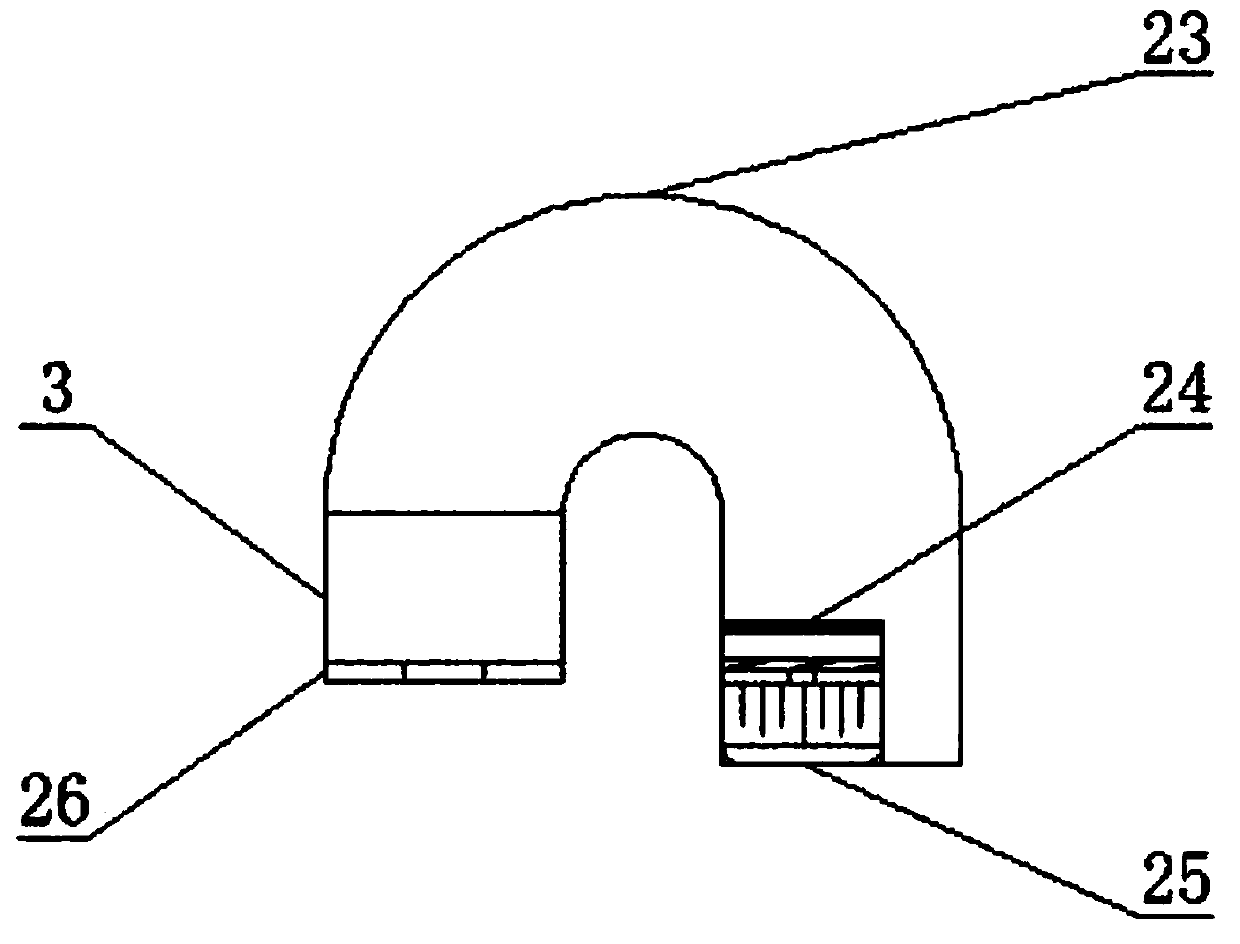

[0015] Such as Figure 1-2 The popping machine shown includes an adjustable support foot 15, a cotton suction pipe 23 and a cotton suction port 26, a support column connecting rod 12 is arranged above the adjustable support foot 15, and a support column connecting rod 12 is provided above the left end. There is a popping machine support post 17, and the right side of the popping machine support post 17 is provided with a transmission wheel support seat 16, and the transmission wheel support seat 16 is provided with a transmission wheel shaft 13, and the outside of the transmission wheel shaft 13 is provided with a transmission wheel 14, and the transmission wheel The right side of 14 is provided with main motor 9, and the middle position of main motor 9 is provided with motor shaft 11, and the below of main motor 9 is provided with motor base 10, and the right side of motor base 10 is provided with aspirator collection bucket 8, The top of the cotton aspirator collection barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com