Uplift pile and construction method thereof

A technology of anti-pull piles and pile bodies, which is applied in the direction of sheet pile walls, foundation structure engineering, protection devices, etc., and can solve the problems of the joints of pile bodies being broken, corroded, bearing pressure and limited compression and pullout capabilities, etc. Achieve the effects of strengthening the strength of the connection, simplifying the process steps, and improving the pull-out resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

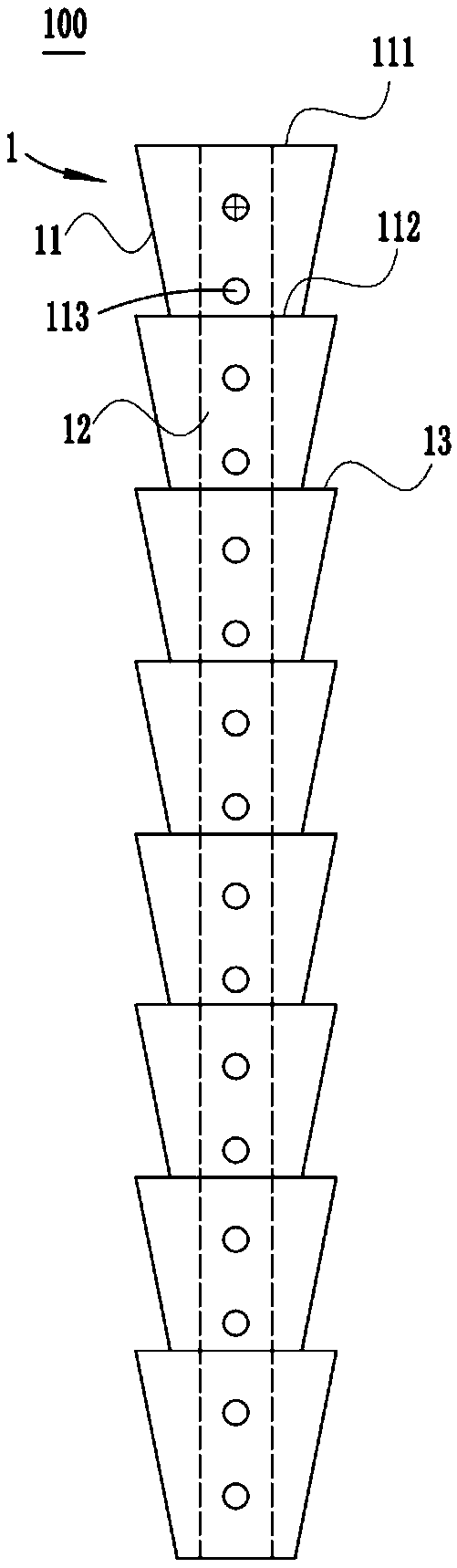

[0032] The first embodiment: according to the attached figure 1 As shown, the uplift pile 100 includes a pile body 1 extending in the vertical direction, a plurality of pile bodies 11 forming the pile body 1 , and a cement slurry flow channel 12 passing through the pile body 1 . Wherein, a plurality of pile bodies 11 are fixedly arranged in sequence. In this example, each pile body 11 has a first end 111 located at the upper part and a second end 112 located at the lower part, and the transverse width of the first end 111 is greater than the transverse width of the second end 112. The second end 112 of one pile body 11 among the pile bodies 11 is fixedly arranged with the first end portion 111 of the other pile body 11 . The joints of the first and second ends protrude outward to form the occlusal portion / barb portion 13 where the uplift pile 100 and the building soil layer are occluded. In other embodiments, a plurality of pile bodies 11 integrally form the pile body 1; two...

no. 2 example

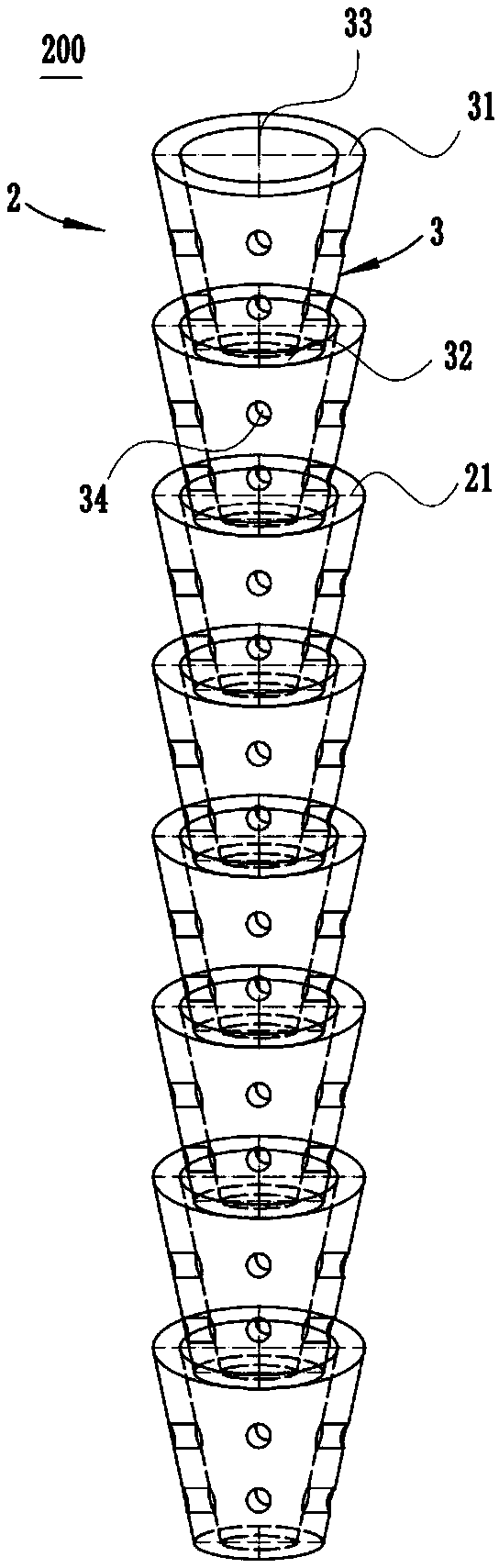

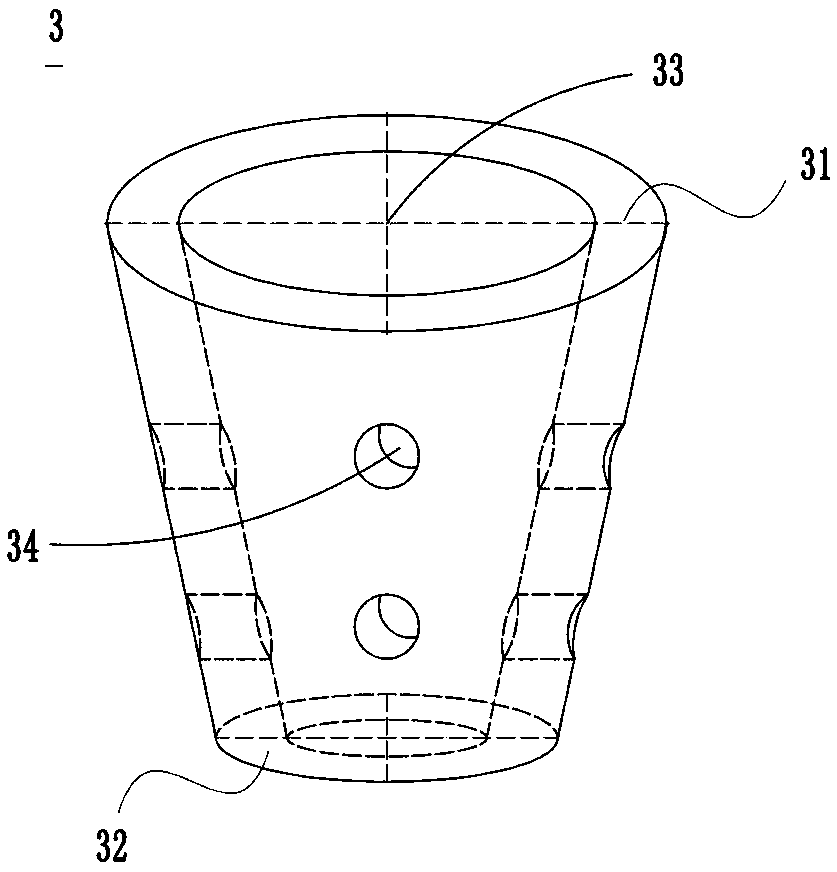

[0035] The second embodiment: according to the attached figure 2 ~ attached Figure 5 As shown, the uplift pile 200 includes a composite pile body 2, which is composed of a plurality of sub-pile bodies 3 nested in each other. Each sub-pile body 3 is an integral part, and each sub-pile body 3 is in the shape of a circular platform. Each sub-pile body 3 has a first open end 31 and a second open end 32 and cement between the first and second open ends. Slurry flow channel 33, the diameter of the first open end 31 is greater than the diameter of the second open end 32, the second open end 32 of one sub-pile body 3 in the adjacent two sub-pile bodies 3 is sleeved on the other sub-pile body 3 Inside the first open end 31, the sleeve joints of the first and second open ends protrude outward to form the occlusal part / hook-shaped part 21 where the uplift pile 200 and the building soil layer interlock, and a plurality of cement slurry flow channels 33 are sequentially connected. In g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com