Piston top surface structure for reducing soot in diesel engine cylinder

A piston crown and diesel engine technology, applied to internal combustion piston engines, pistons, mechanical equipment, etc., can solve the problem that the oil-gas mixing state of the combustion chamber pit cannot be completely changed, so as to improve the oxidation rate of soot and reduce the emission of soot in the cylinder , Improve the effect of oil-gas mixing state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

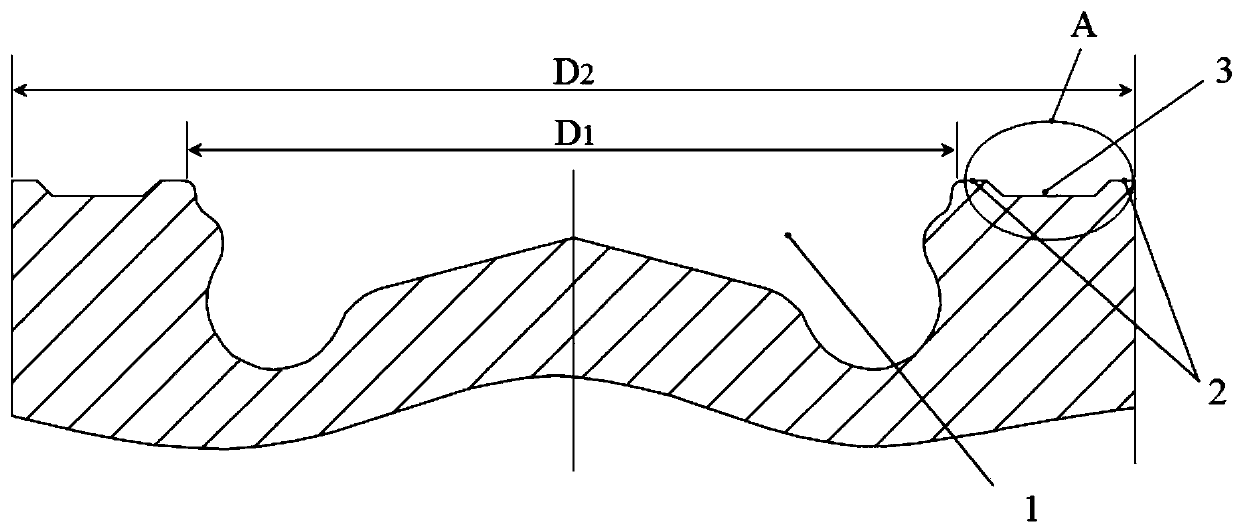

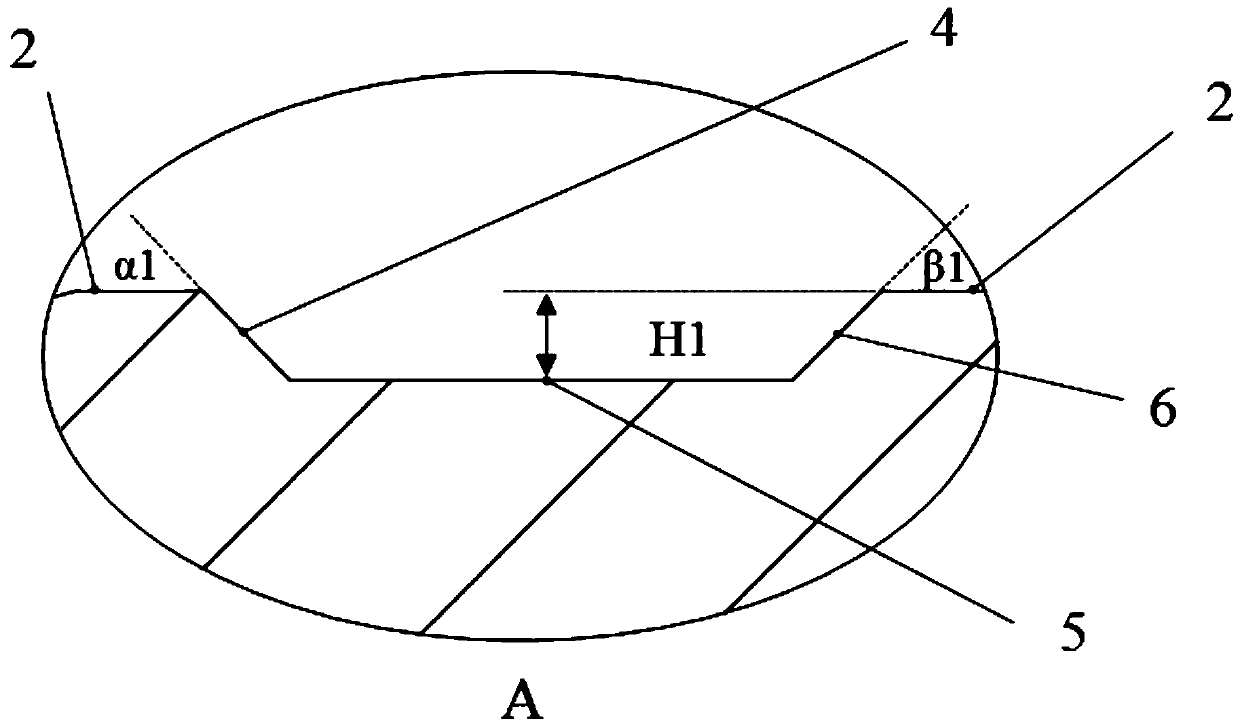

[0024] Such as figure 1 and figure 2 As shown, a kind of piston top surface structure that reduces soot in the diesel engine cylinder of the present invention is to dig a soot oxidation annular groove 3 whose cross-sectional shape is an inverted trapezoid on the piston top surface 2, and the inverted trapezoidal soot oxidation annular groove 3 The included angles between the two waistlines, i.e., the discharge slope 4 and the flow blocking wall 6, and the piston top surface 2 are α 1 =30~70°, β 1 =30~70, the ring groove bottom 5 is connected smoothly with the discharge slope 4 and the flow blocking wall 6, the distance H between the ring groove bottom 5 and the piston top surface 2 1 The soot oxidation ring groove 3 is coaxial with the combustion chamber 1, and its upper top surface is a part of the piston top surface 2, and its radial position is formed by the intersection of the highest point of the combustion chamber 1 and the piston top surface 2 circle (diameter D 1 ...

Embodiment 2

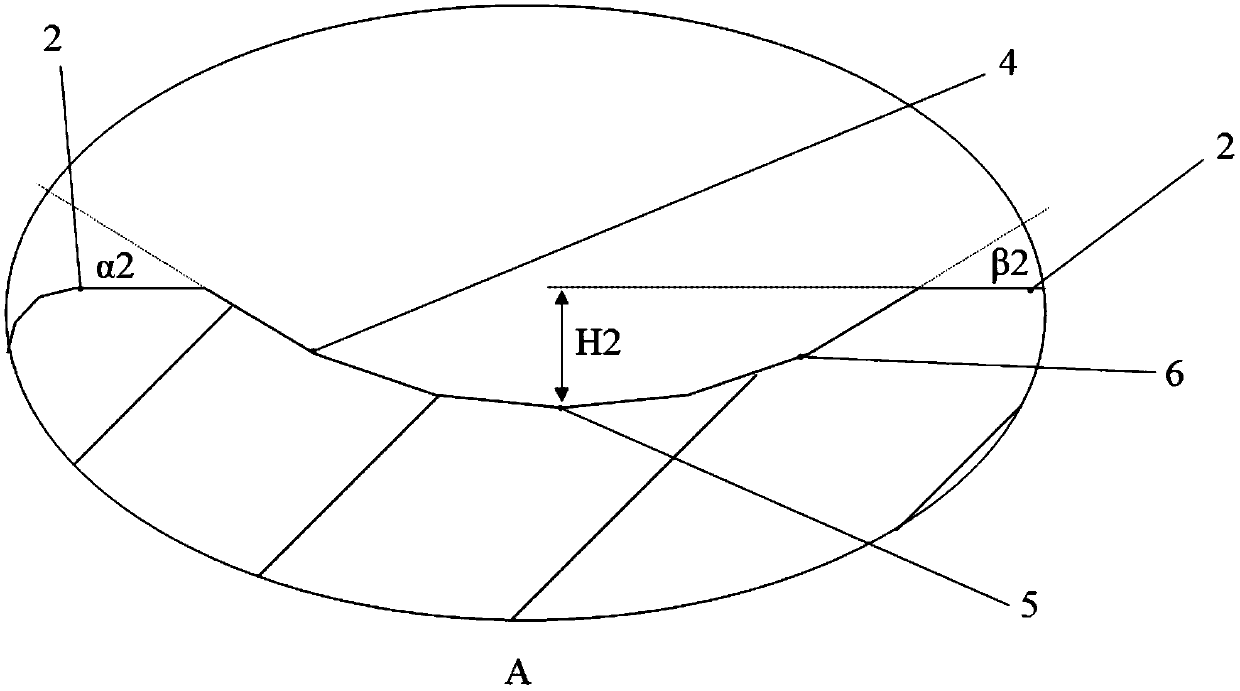

[0026] Such as figure 1 and image 3 As shown, a piston top surface structure for reducing soot in a diesel engine cylinder of the present invention is to dig a soot oxidation annular groove 3 with a cross-sectional shape that is a left-right symmetrical arc on the piston top 2, and the left-right symmetrical arc soot oxidation The angle between the discharge slope 4 of the ring groove 3 and the piston top surface 2 is α 2 =30~70°, the included angle between the blocking wall 6 of the soot oxidation ring groove 3 and the piston top surface 2 is β 2 =30~70°, the ring groove bottom 5 is smoothly transitioned to the discharge slope 4 and the blocking wall 6, and the distance H between the ring groove bottom 5 and the piston top surface 2 2 The soot oxidation ring groove 3 is coaxial with the combustion chamber 1, and its upper top surface is a part of the piston top surface 2, and its radial position is formed by the intersection of the highest point of the combustion chamber 1...

Embodiment 3

[0028] Such as figure 1 and Figure 4 As shown, a piston top surface structure for reducing soot in the diesel engine cylinder of the present invention is to dig a soot oxidation annular groove 3 with a cross-sectional shape that is shallow on the left and deep on the right and deep on the piston top surface. The included angle between the discharge slope 4 of the deep asymmetric arc-shaped soot oxidation ring groove 3 and the piston top surface 2 is α 3 =10~40°, the included angle between the blocking wall 6 of the soot oxidation ring groove 3 and the piston top surface 2 is β 3 =60~90°, the ring groove bottom 5 is smoothly connected with the discharge slope 4 and the flow blocking wall 6, the distance H between the ring groove bottom 5 and the piston top surface 2 3 The soot oxidation ring groove 3 is coaxial with the combustion chamber 1, and its upper top surface is a part of the piston top surface 2, and its radial position is formed by the intersection of the highest p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com