Textile yarn ball drying device capable of rotating obliquely

The invention relates to a drying equipment and a technology of tilting and rotating, which is applied in the field of yarn ball drying equipment for textiles, and can solve the problems of inconvenient drying and small heating area of the yarn ball drying operation, so as to facilitate heat dissipation, improve work efficiency, and achieve better effects. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

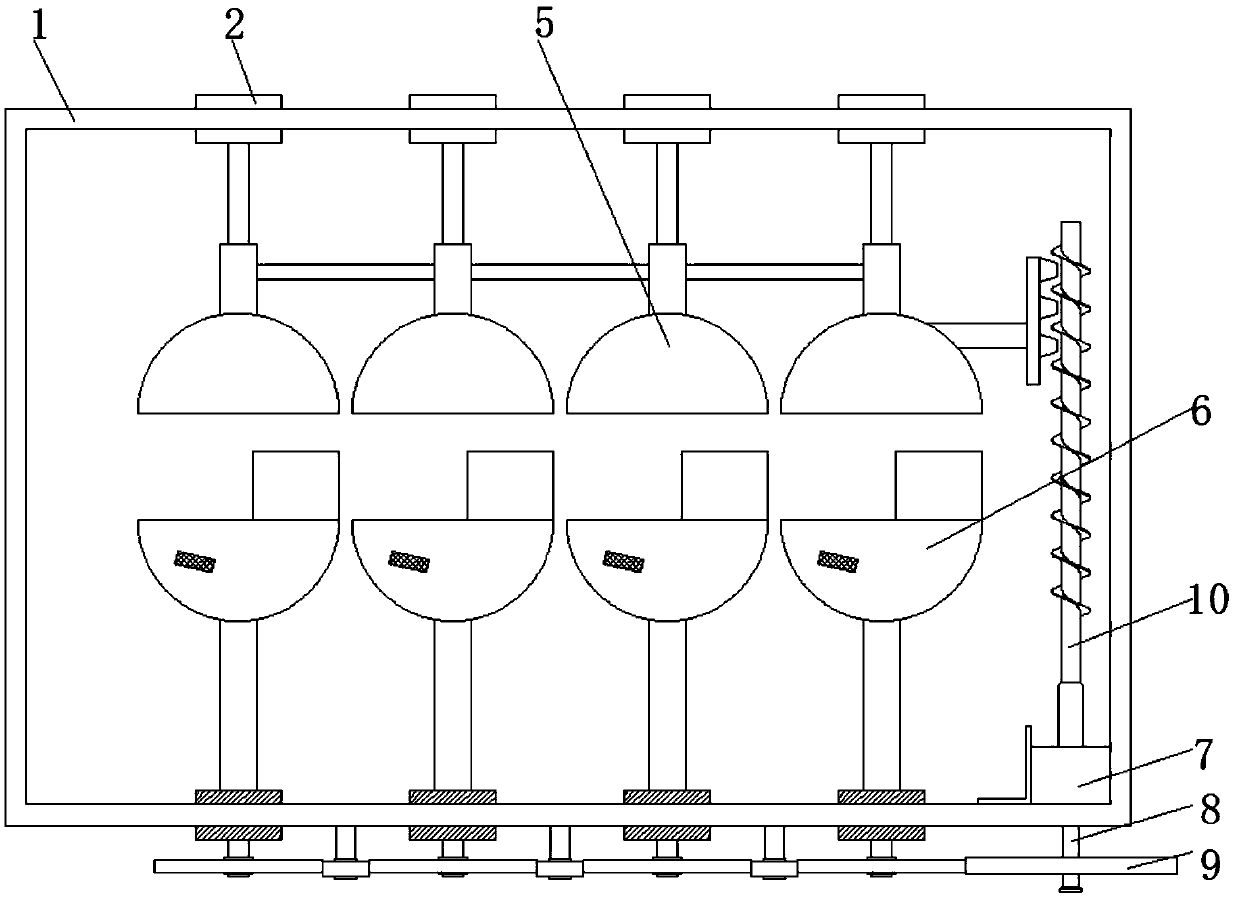

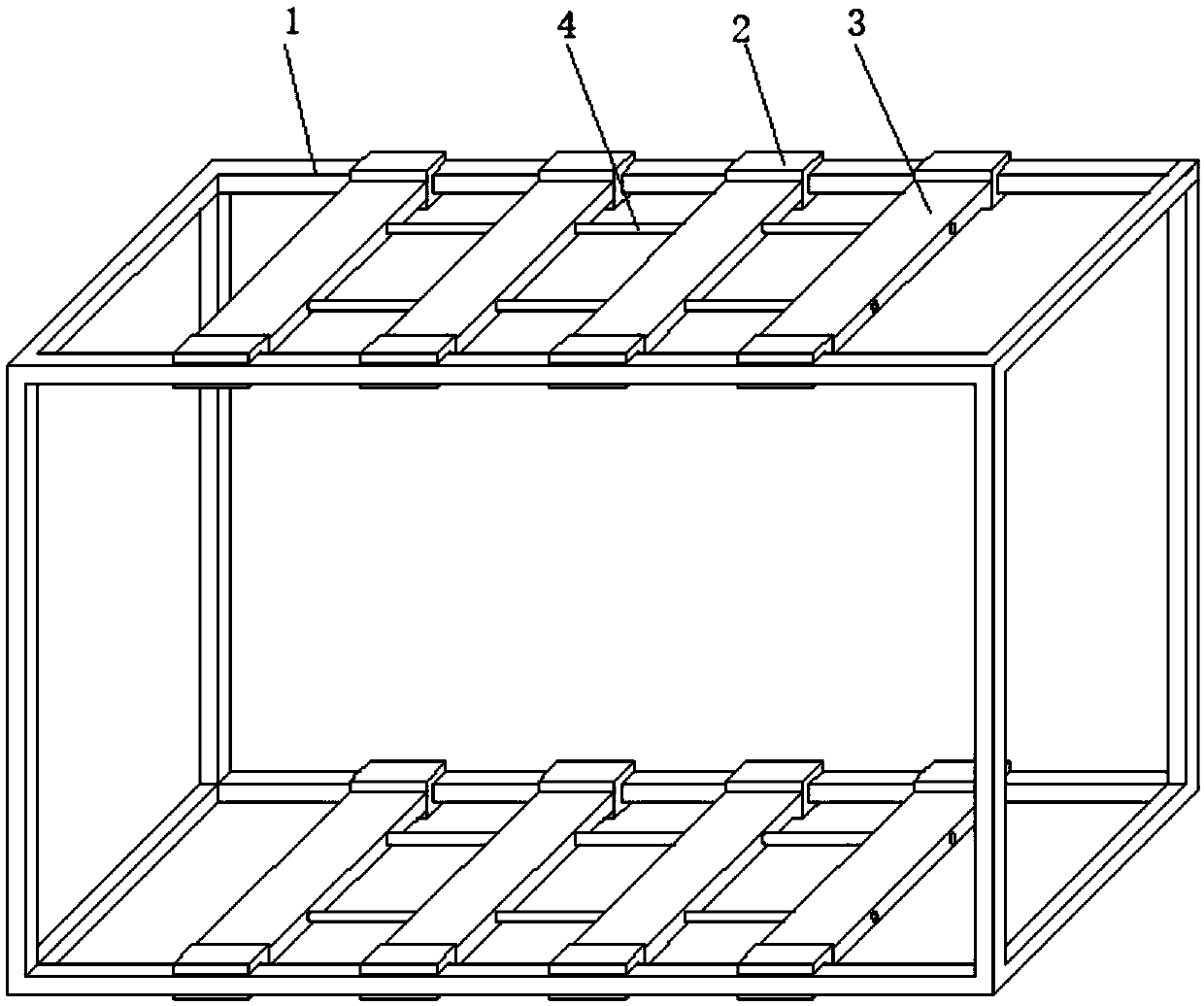

[0041] Such as Figure 1-2 As shown, the present invention provides a technical solution: a tiltable and rotatable textile yarn ball drying equipment, comprising a cube frame 1, two prisms at the top of the frame 1 and two prisms at the bottom of the frame 1 are fixedly connected with 4-8 groups of C-shaped cardboards 2, and between the two C-shaped cardboards 2 at the top and between the two C-shaped cardboards 2 at the bottom are fixedly connected with a placement plate 3, and the adjacent An arc-shaped guide tube 4 is fixedly connected between the two placement plates 3, a centralized drying treatment mechanism 5 is provided at the bottom of the C-shaped pallet 2 located above, and a centralized drying treatment mechanism 5 is arranged at the bottom of the C-shaped pallet 2 located below. Anti-action force rotation mechanism 6, the lower right corner of the square frame 1 is fixedly connected with a bidirectional motor 7 through the L-shaped reinforcing plate, the output en...

Embodiment 2

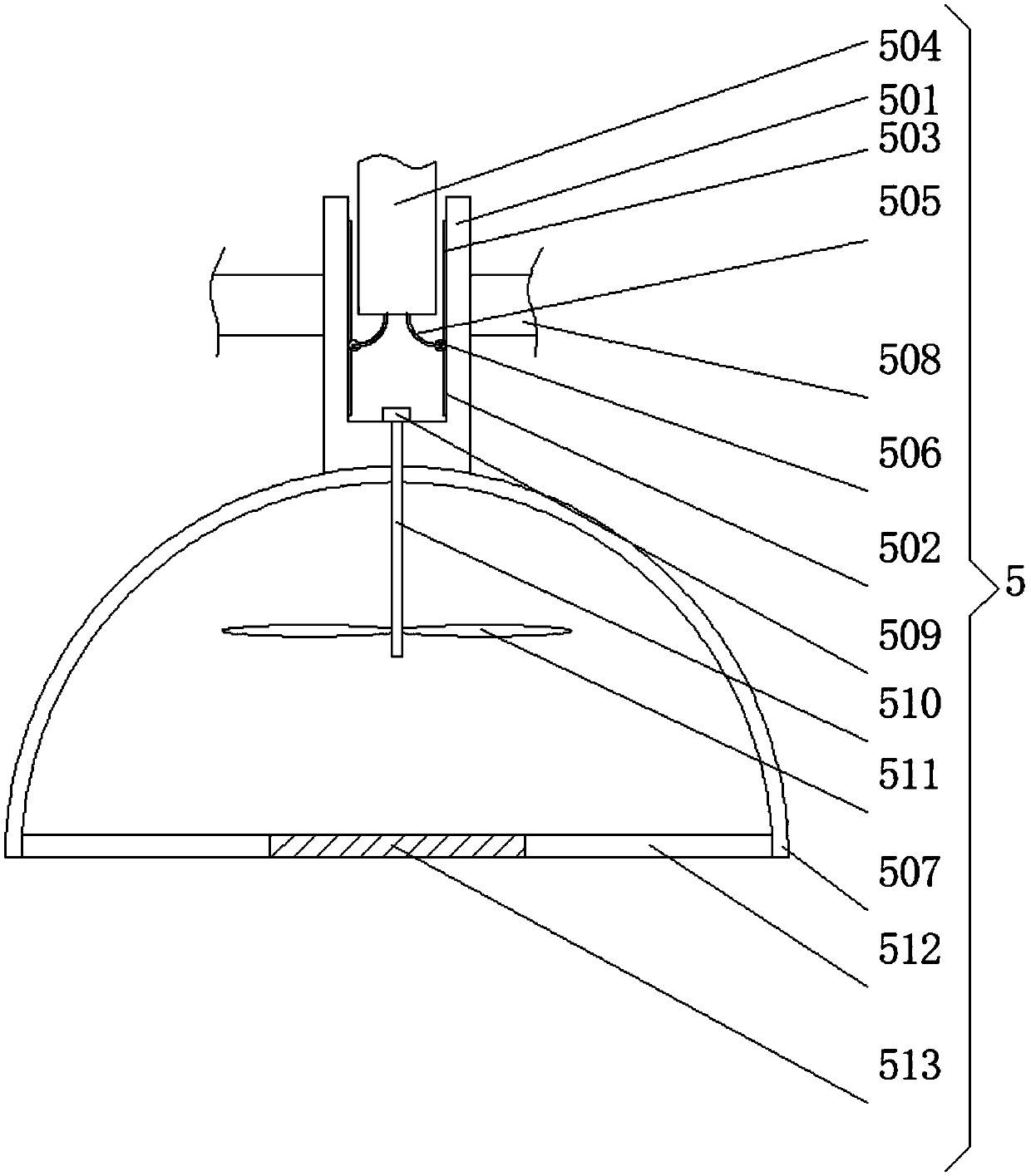

[0043] Such as Figure 1-4 As shown, a tilting and rotating textile yarn ball drying equipment includes a cube frame 1, and the two prisms on the top of the frame 1 and the two prisms on the bottom of the frame 1 are fixedly connected with 4-8 sets of C-shaped cards. board 2, and between the two C-shaped card boards 2 at the top and the two C-shaped card boards 2 at the bottom are fixedly connected with the placement board 3, and the two adjacent placement boards 3 are fixed It is connected with an arc-shaped guide pipe 4, and the bottom of the upper C-shaped pallet 2 is provided with a centralized drying treatment mechanism 5, and the bottom of the lower C-shaped pallet 2 is fixedly connected with an anti-force rotating mechanism 6. The lower right corner of the frame 1 is fixedly connected to the bidirectional motor 7 through the L-shaped reinforcing plate, the output end of the bottom of the bidirectional motor 7 is fixedly connected to the output end, and the output end is...

Embodiment 3

[0046] Such as Figure 1-7 As shown, a tilting and rotating textile yarn ball drying equipment includes a cube frame 1, and the two prisms on the top of the frame 1 and the two prisms on the bottom of the frame 1 are fixedly connected with 4-8 sets of C-shaped cards. board 2, and between the two C-shaped card boards 2 at the top and the two C-shaped card boards 2 at the bottom are fixedly connected with the placement board 3, and the two adjacent placement boards 3 are fixed It is connected with an arc-shaped guide pipe 4, and the bottom of the upper C-shaped pallet 2 is provided with a centralized drying treatment mechanism 5, and the bottom of the lower C-shaped pallet 2 is fixedly connected with an anti-force rotating mechanism 6. The lower right corner of the frame 1 is fixedly connected to the bidirectional motor 7 through the L-shaped reinforcing plate, the output end of the bottom of the bidirectional motor 7 is fixedly connected to the output end, and the output end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com