Falling tension fatigue test device for power construction safety belt

A tensile fatigue and electrical construction technology, which is applied in the application of repetitive force/pulse force to test the strength of materials, measuring devices, instruments, etc., can solve the problem that the impact debris of the counterweight is easy to splash and hurt people, the test interval is long, and the efficiency Low-level problems, to achieve the effect of shortening the test interval time and solving inefficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

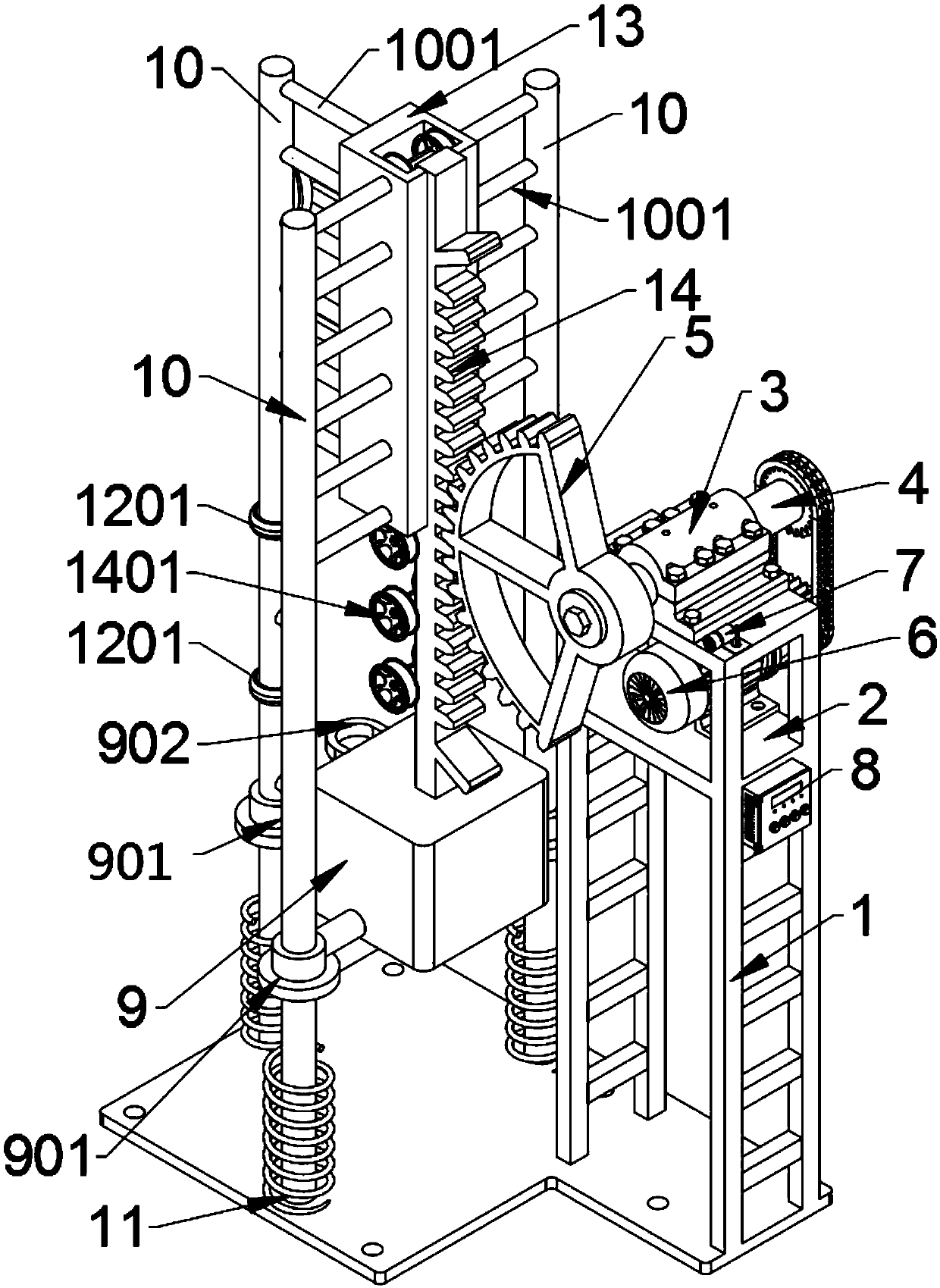

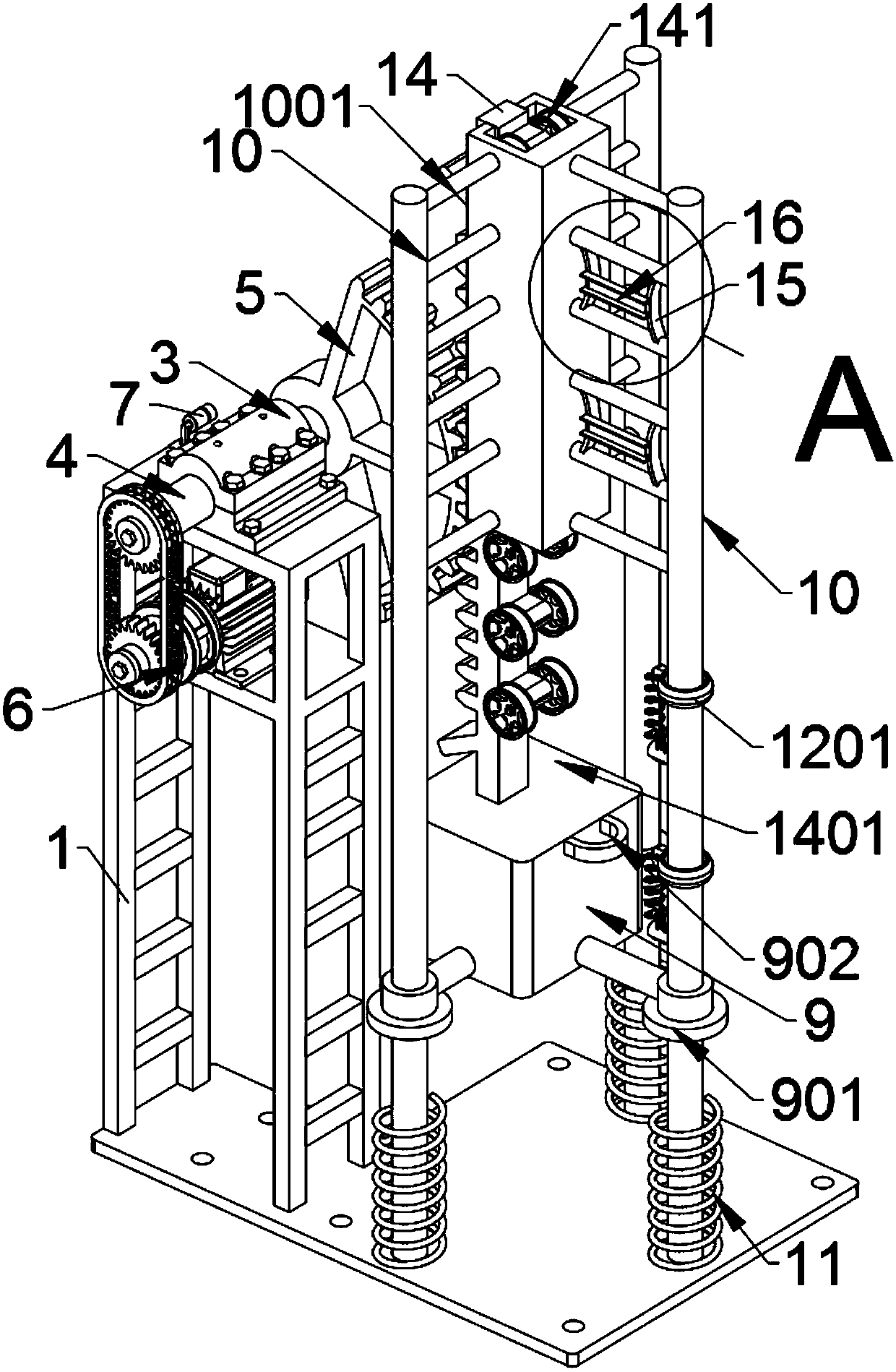

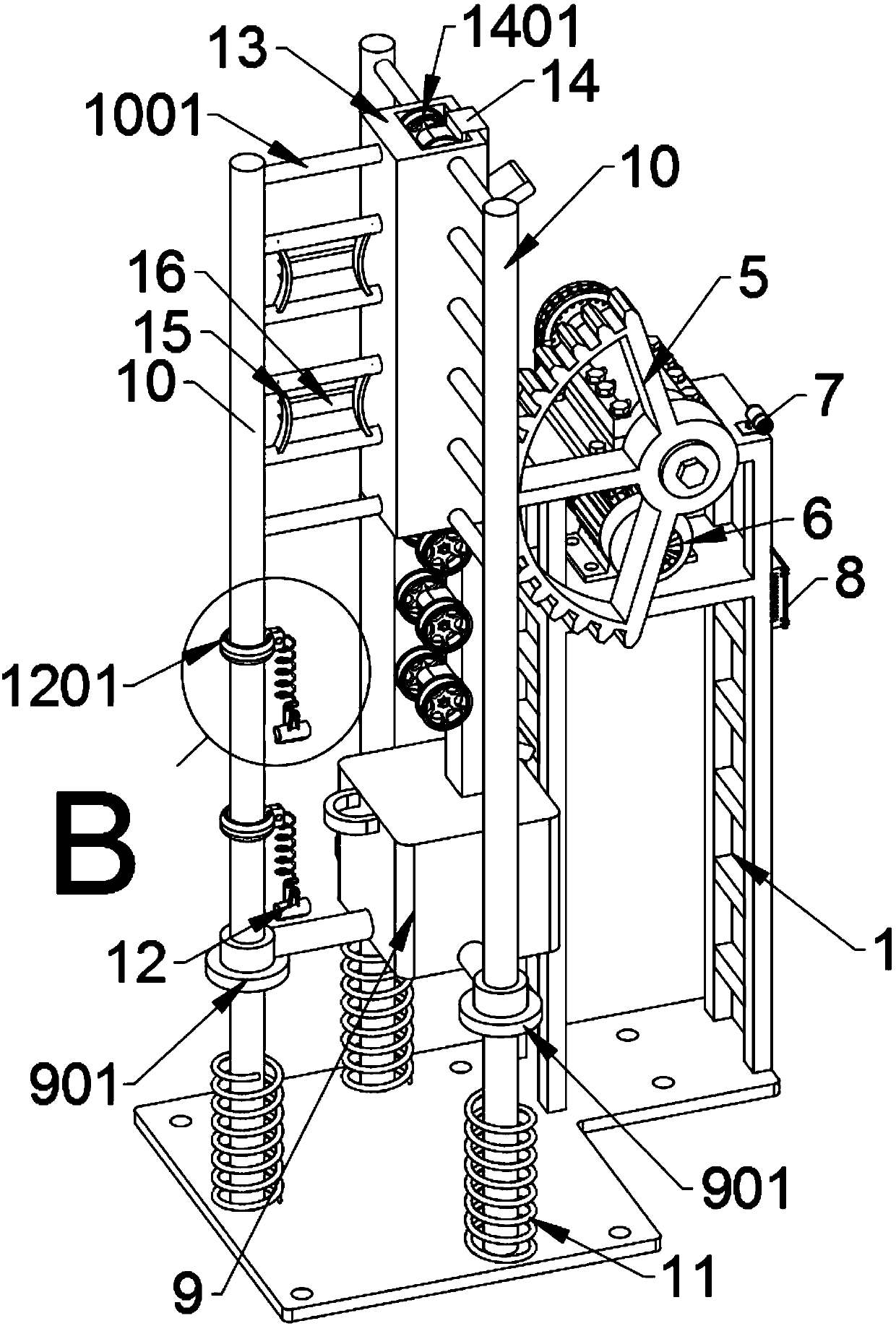

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034]The invention provides a drop tension fatigue test device for safety belts in electric power construction, which includes a supporting mounting frame 1, a motor mounting plate 2, a bearing seat 3, a rotating shaft 4, a sector gear 5, a driving motor 6, a photoelectric sensor switch 7, and a control Electric box 8, lead block 9, positioning ring 901, hanging ring 902, support shaft 10, welding strut 1001, buffer spring 11, clip 12, slip ring 1201, pin 1202, track groove 13, sliding hanging plate 14, roller 1401, the arc-shaped support plate 15 and the leaning groove 16, the support installation frame 1 is welded and supported on the rear side of the base plate protruding from the rectangular plate, and the top of the support installation frame 1 is screwed and fixed with a bearing seat 3; A motor mounting plate 2 is supported and welded between the supporting mounting frames 1, and the motor mounting plate 2 is lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com