Detection device, method and system for internal defect of ceramic insulator

A technology for porcelain insulators and internal defects, which is applied in the field of detection devices for internal defects of porcelain insulators, can solve the problems of difficult identification of defects, low detection efficiency, and detection blind spots, etc., and achieves a large single measurement area, comprehensive processing and analysis, measurement fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

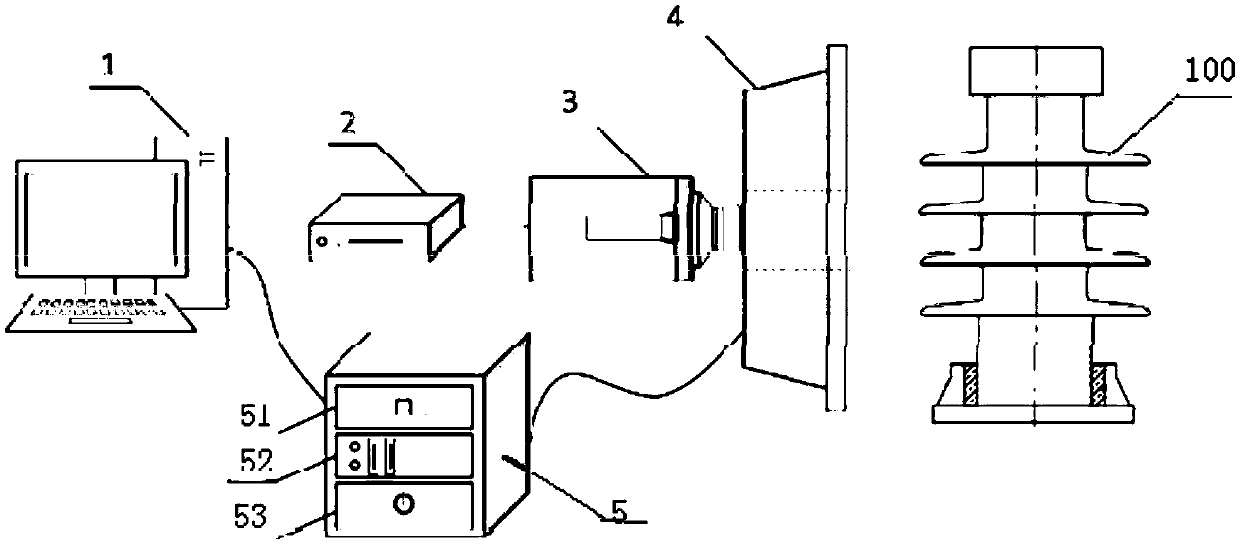

[0062] see figure 1 , which is a structural schematic diagram of a detection device for internal defects of porcelain insulators of the present application;

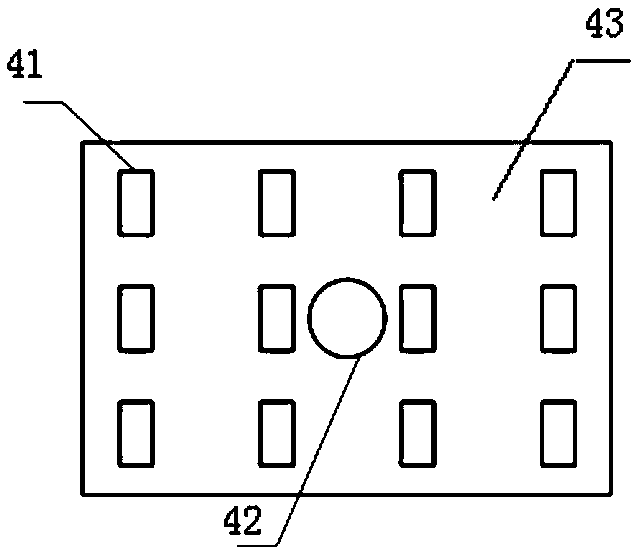

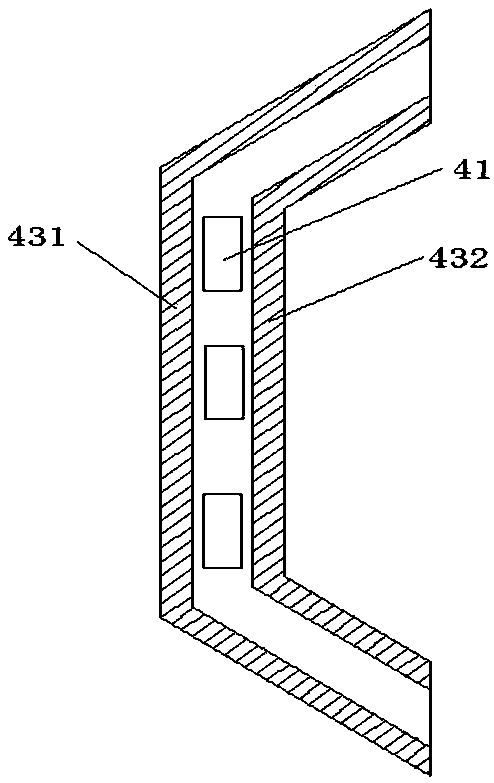

[0063] see figure 2 , which is a schematic diagram of the local structure of the pulse emission device in a detection device for internal defects of porcelain insulators of the present application;

[0064] Depend on figure 1 and figure 2 It can be seen that the embodiment of the present application provides a detection device for internal defects of porcelain insulators. The detection device includes a data processor 1, an infrared thermal image acquisition device and an optical pulse thermal excitation loading device, wherein,

[0065] The output terminal of the data processor 1 is electrically connected to the infrared thermal image acquisition device;

[0066] The infrared thermal image acquisition device includes an infrared thermal imager 3 and a data acquisition card 2 electrically connected to each other; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com