Quickly connectable conductive stud structure

A quick connection and stud technology, which is applied in the direction of connection and connection device components, circuits, etc., can solve the problems of appearance traces, deformation, and reduced appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

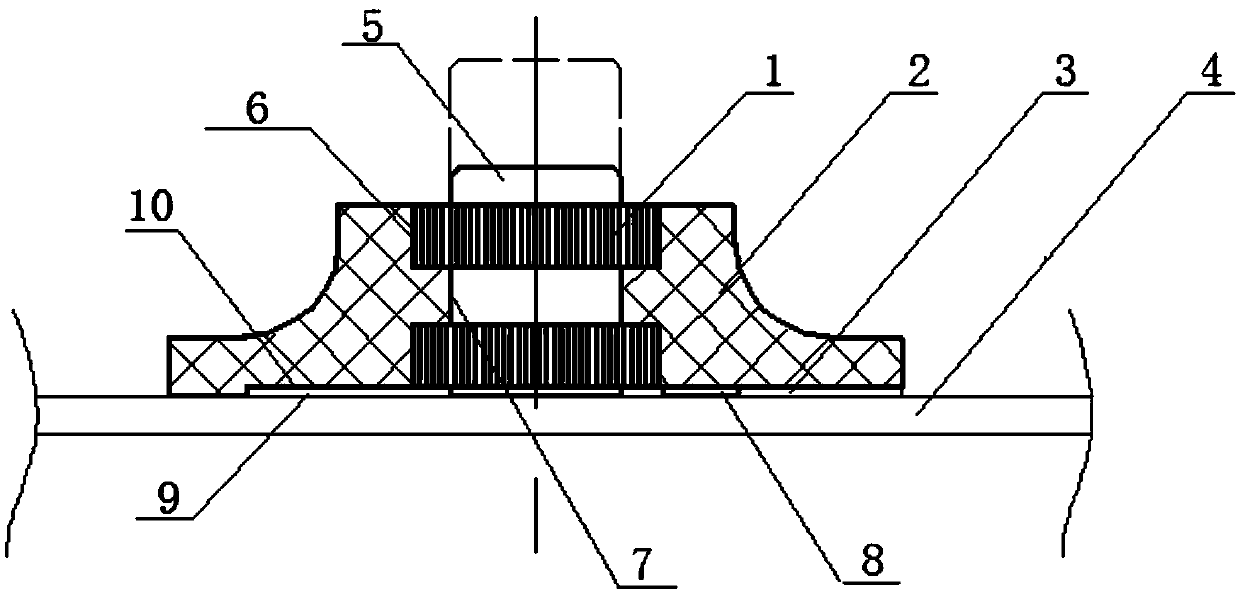

[0023] Such as figure 1 As shown, a quick-connect conductive stud structure includes a sheet metal part 4, a UV adhesive layer 3, a transparent base 2, a metal insert 1 and a stud 5.

[0024] The sheet metal part 4 may be a processing-free sheet such as SGCC, SECC, 304, etc.

[0025] The UV glue layer 3 is specifically formed by curing Dymax (4-20418) UV glue through ultraviolet (UV) irradiation, and other types of UV glue can also be used. As long as the UV glue can be cured to bond the sheet metal part 4 and the transparent base 2 together after being irradiated by ultraviolet rays, the requirement is met. This embodiment only takes Dymax (4-20418) UV glue as an example.

[0026] The transparent base 2 adhered to the sheet metal part 4 by the UV adhesive layer 3, the purpose of setting the transparent base 2 is that it can transmit ultraviolet (UV), use ultraviolet (UV) to pass through the transparent base 2 and then irradiate the coated Dymax (4-20418) UV glue, curing the UV glu...

Embodiment 2

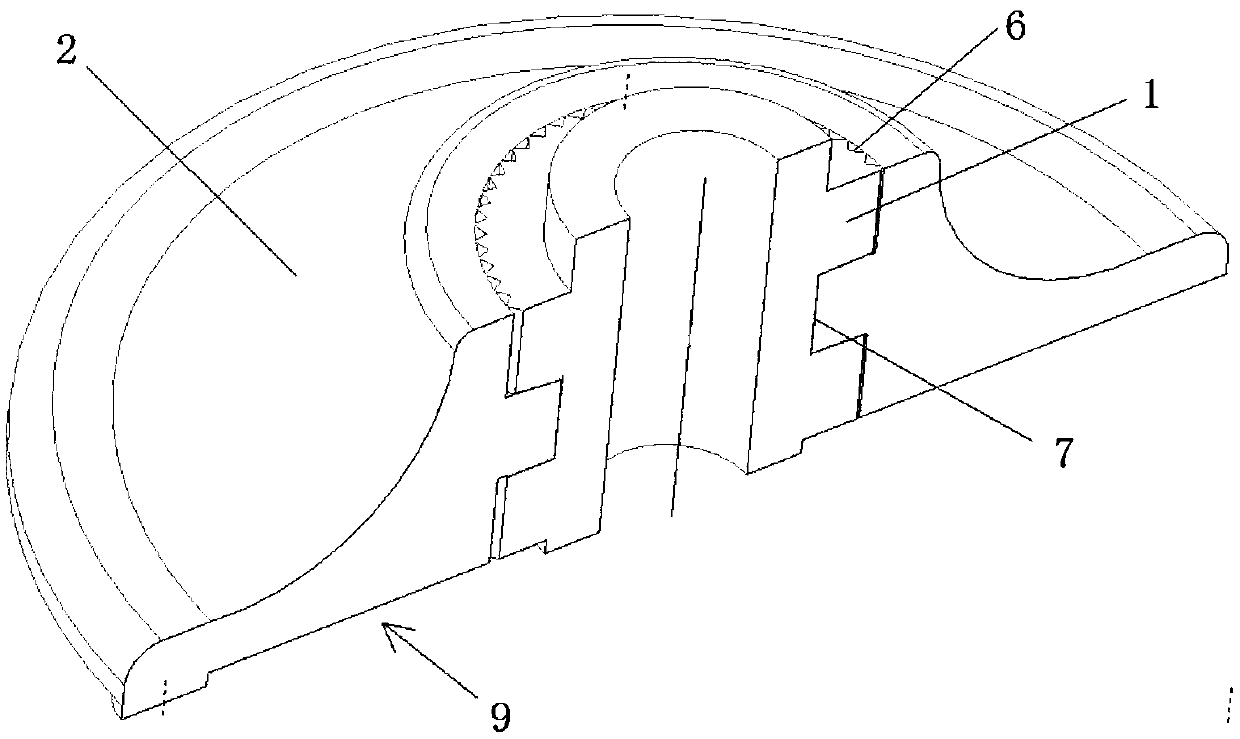

[0034] On the basis of Embodiment 1, a receiving groove is added at the bottom of the transparent base 2. The bottom of the transparent base 2 mentioned here refers to the end where the transparent base 2 and the sheet metal part 4 are connected. The bottom of the transparent base 2 is provided with a accommodating groove 9 for accommodating UV glue, and a leg 8, and the leg 8 is located in the accommodating groove 9, and the leg 8 is supported on the sheet metal 4 and filled in the accommodating The UV glue layer 3 in the groove 9 is connected to the sheet metal part 4. The accommodating groove 9 is provided so that the UV adhesive layer 3 only exists in the accommodating groove 9, and the thickness of the UV adhesive layer 3 and the amount of UV adhesive can be accurately controlled, thereby controlling the height of the entire conductive stud structure. When the top of the stud 5 is connected to the PCB board, the height of the stud 5 is required. Adopting the conductive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com