Operating method for electric hydraulic water spraying unit of ship propulsion system

A technology of propulsion system and operation method, which is applied in the field of operation of electro-hydraulic water jet unit of ship propulsion system, can solve the problems of frequent maintenance, influence on installation, fast wear of components, etc., and achieve good mute effect, convenient maintenance and large driving force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

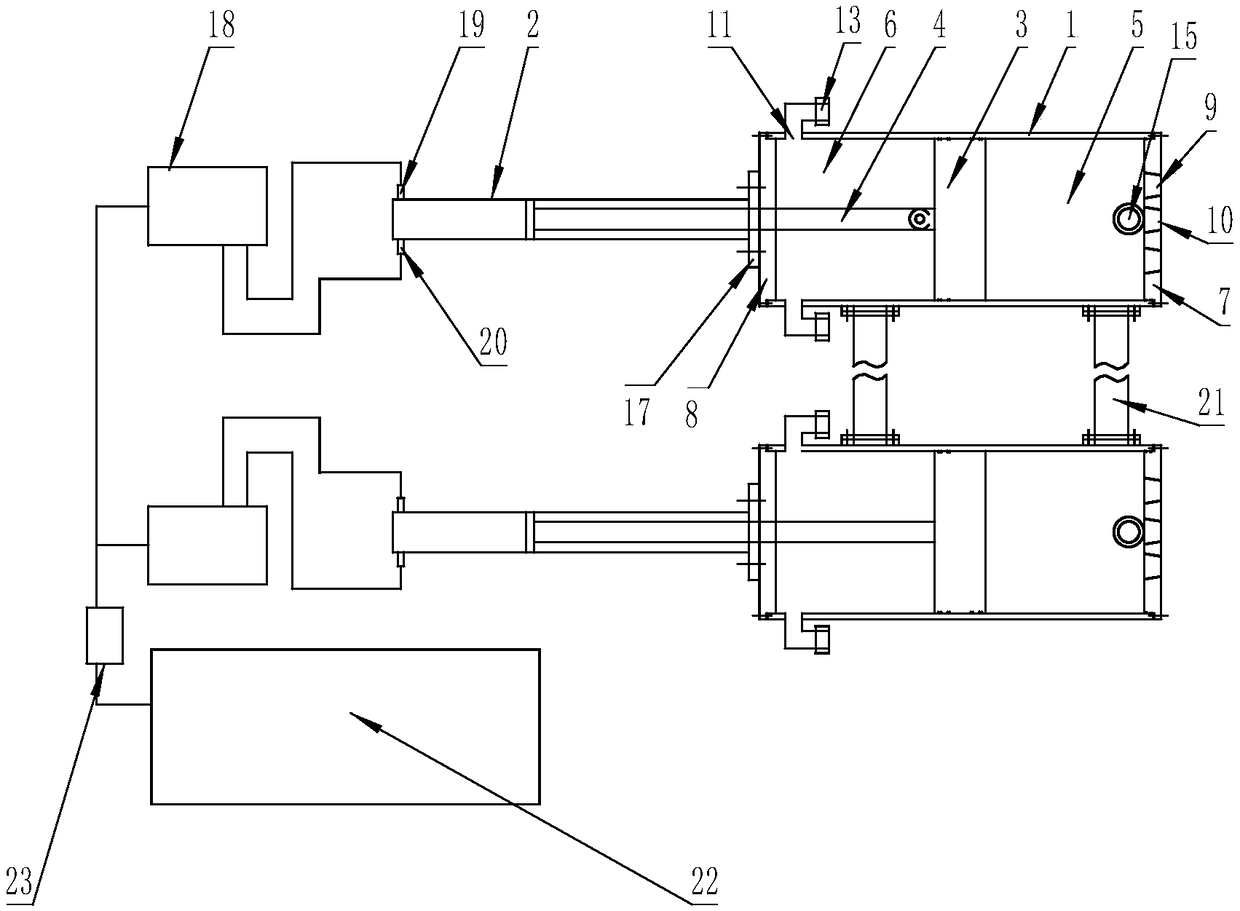

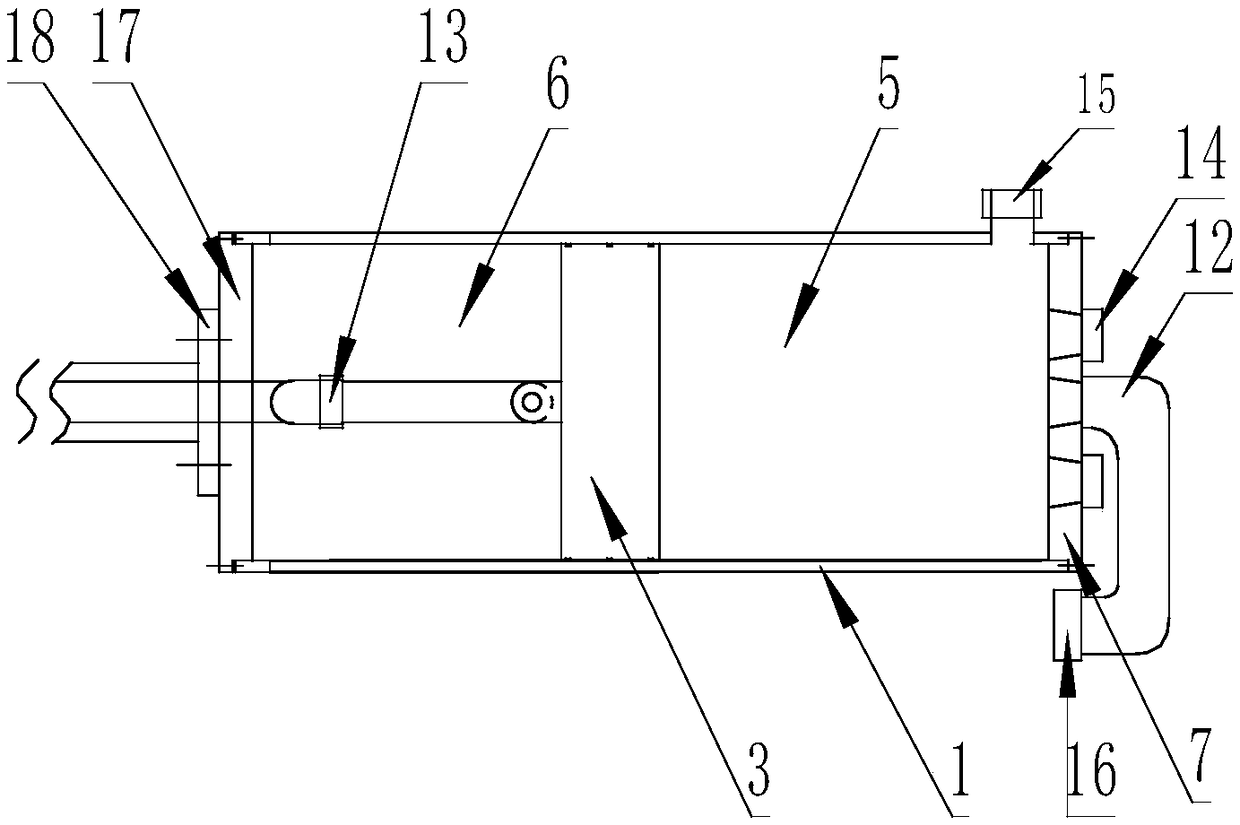

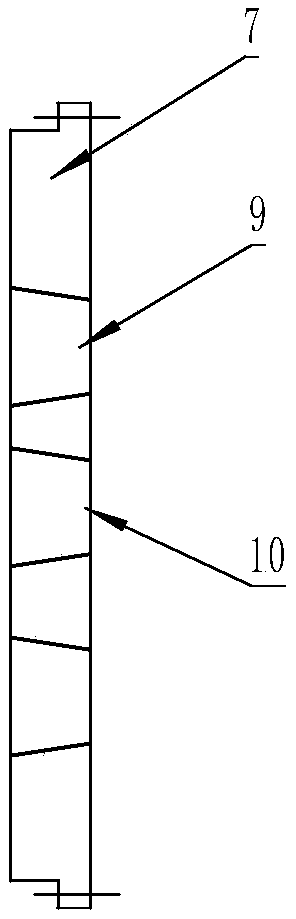

[0022] At least two water pressure chamber bodies 1 are arranged symmetrically on both sides of the electrohydraulic water jet propulsion device, and pressure chamber body connecting plates 21 are respectively arranged between the front and rear parts of the two water pressure chamber bodies 1; the rear end of the water pressure chamber body 1 The hydraulic cylinder 2 is set respectively, the hydraulic inlet 19 and the hydraulic outlet 20 are respectively arranged on both sides of the rear end of the hydraulic cylinder 2, and the two-way hydraulic pump station 18 is arranged on one side of the hydraulic cylinder 2, and the two-way hydraulic pump station 18 is connected with the hydraulic inlet 19 and the hydraulic outlet respectively. Oil pressure pipelines are set between 20; battery packs 22 are set on one side of the two-way oil pressure pump station 18, circuits are set between the battery pack 22 and the two-way oil pressure pump station 18 respectively, and a circuit contr...

Embodiment 2

[0027] The hydraulic cylinders 2 on both sides drive the hydraulic pistons 3 in the two hydraulic pressure chambers 1 on both sides to advance and retreat simultaneously.

Embodiment 3

[0029] When the hydraulic piston 3 in one side of the water pressure chamber body 1 is advancing, the second water inlet valve 13 at the end of the water inlet chamber 6 is opened for water intake, and at the same time, the forward solenoid valve 14 is opened to spray water; the water pressure chamber The body 1 is advanced by the reaction force of the water spray of the forward solenoid valve 14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com