Floating crane ship

A floating crane and hull technology, applied in ship parts, ship construction, anchoring arrangements, etc., can solve the problems of small deck area, high platform cost, inability to turn foundation piles in the air, etc., saving engineering costs and widening construction scope. , the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, and this embodiment does not constitute a limitation to the present invention.

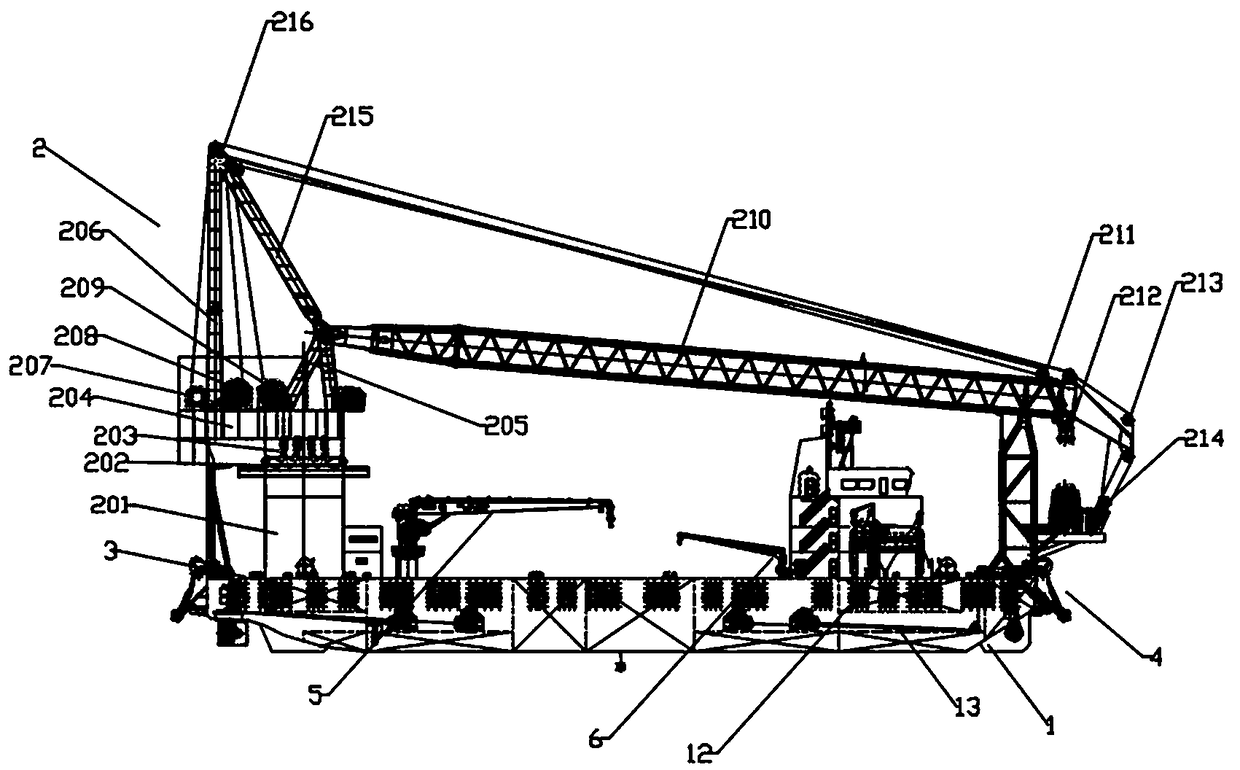

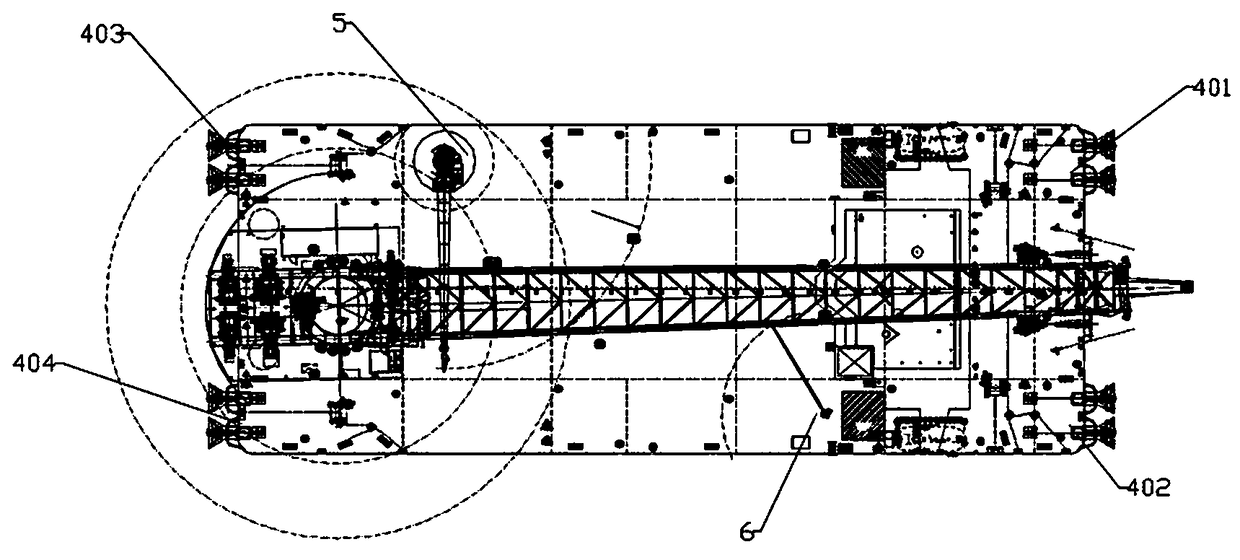

[0032] A floating crane, including a hull 1, a full-slewing main crane 2, a main deck 3, an eight-point positioning mooring system 4, a first gram crane 5, a second gram crane 6, a first slewing thruster 7, a second Rotary propeller 8, first ballast water tank 9, heel adjustment water tank 10, second ballast water tank 11, living building 12 and bottom deck 13.

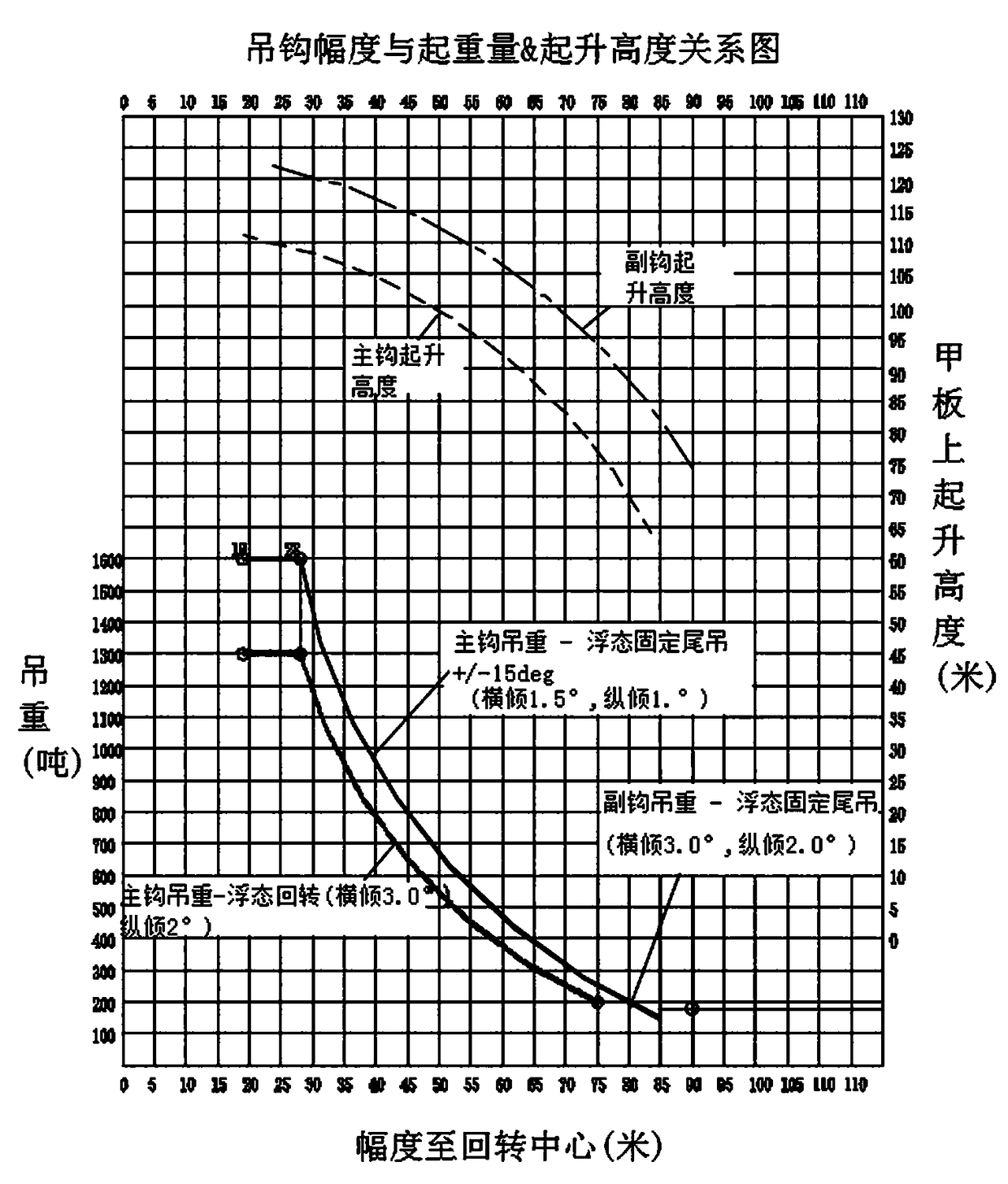

[0033] refer to Figure 1-4 , the hull 1 is provided with a full-turn main crane 2, and the full-turn main crane 2 includes a base 201, a full-turn bearing 202, a slewing mechanism 203, a turntable 204, an articulated frame 205, a support frame 206, a first winch 207, a second Winch 208, the third winch 209, jib 210, main hook pulley block 211, main hook 212, auxiliary hook pulley block 213, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com