Smooth template system with arc side for cast-in-situ deformed beam

A clear water formwork and arc technology, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and on-site preparation of building components, can solve the problem of high production cost, complex surface processing, Template self-importance and other problems, to achieve the effect of saving production cost, shortening construction period, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

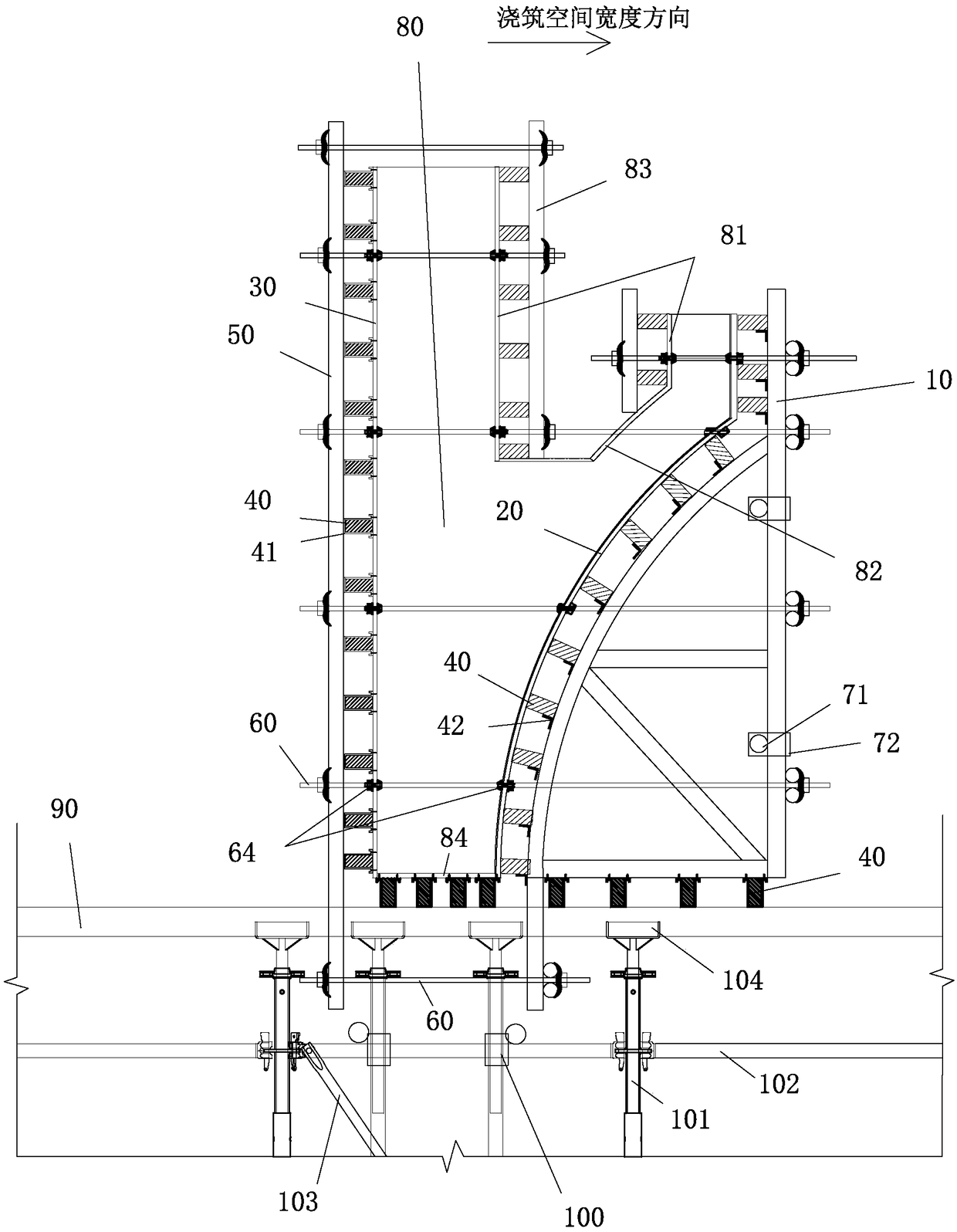

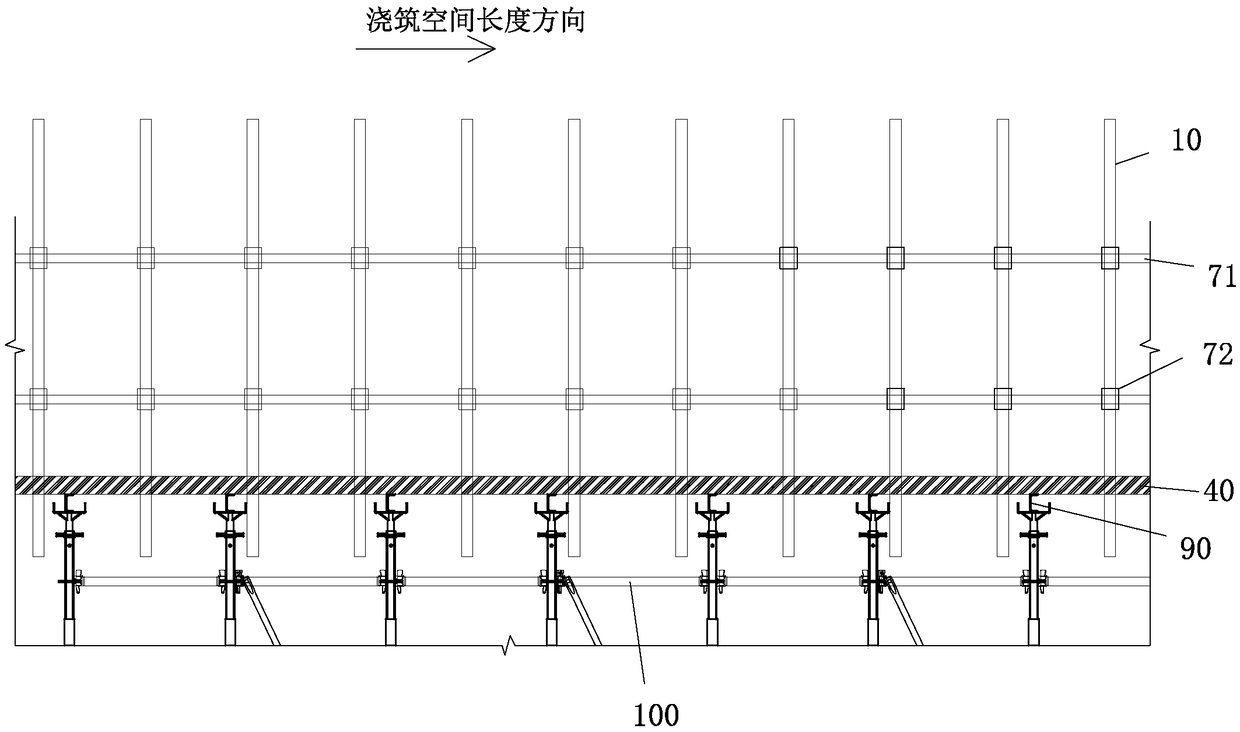

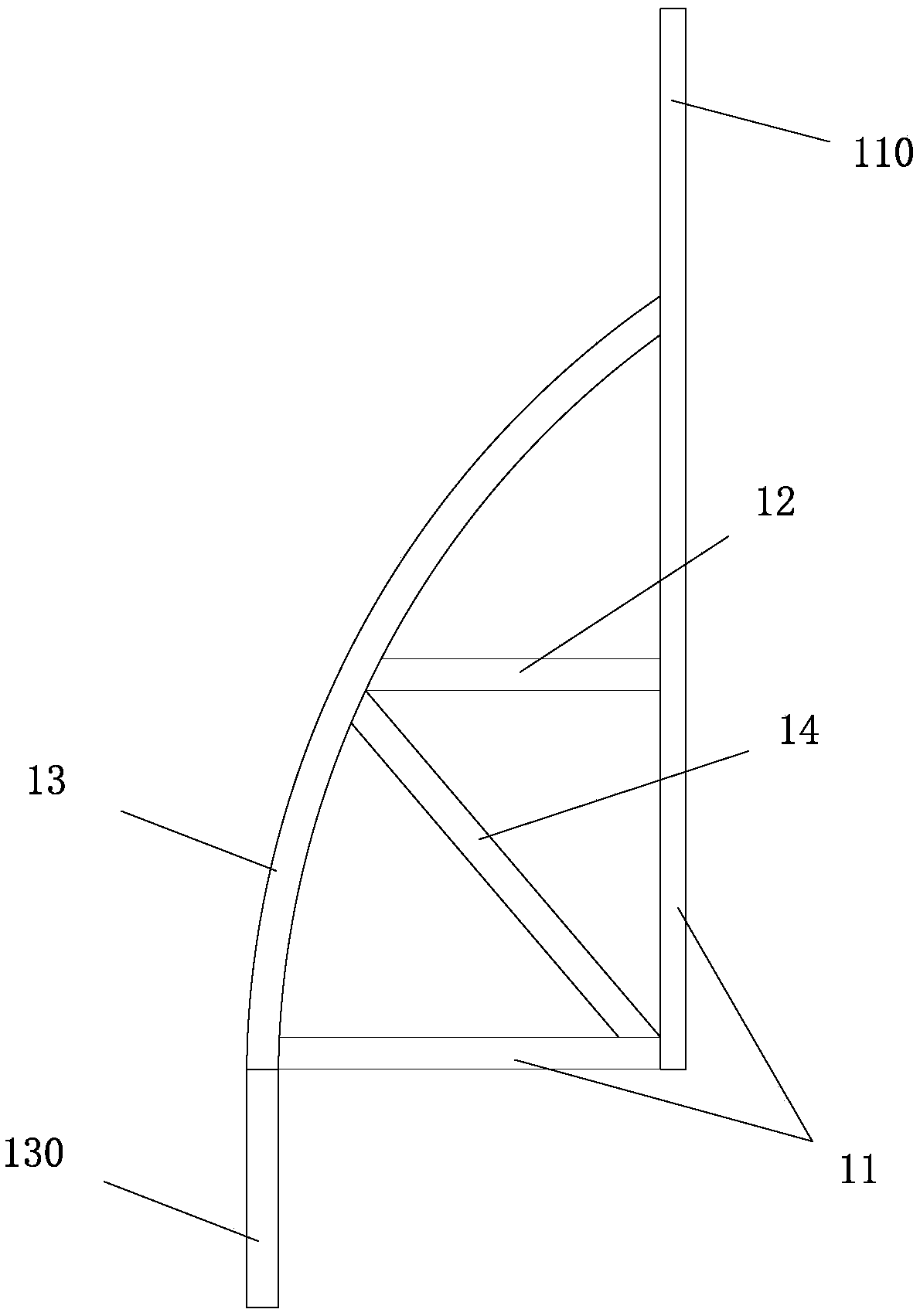

[0022] Such as Figure 1 to Figure 10 As shown, the clear water formwork system for cast-in-place special-shaped beams with arc-shaped sides of the present invention includes a straight face clear water formwork 30 vertically arranged on one side and an arc surface clear water formwork 20 arranged in an arc-shaped bend on the other side, facing the clear water formwork 30 and arc surface clear-water formwork 20 form the pouring space 80 for pouring fair-faced concrete 200 together with the bottom formwork 84 (bottom formwork 84 adopts clear-water formwork or other type formworks) that is at the bottom and is horizontally arranged, and the pouring space 80 is on its length direction The two ends of the two sides usually adopt a straight-face formwork system (such as a straight-face clear water formwork 30); a number of wooden beams 40 arranged at intervals up and down on the outside of the straight-face clear water formwork 30 as a secondary keel pass through such as iron wires ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com