Method for building up pressure in sections of exhaust after-treatment system

A tail gas post-treatment and stage technology, which is applied in the direction of electronic control of exhaust treatment devices, exhaust treatment, special data processing applications, etc., can solve problems such as pressure build-up failure, system pipeline impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

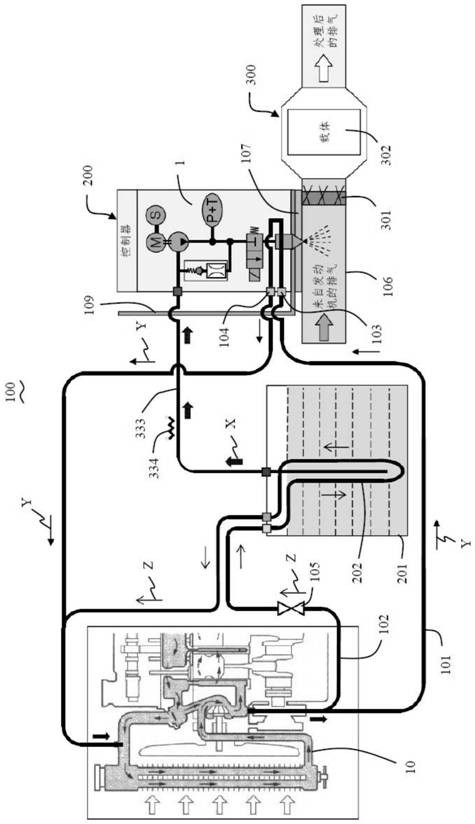

[0094] Please refer to figure 1 As shown, the present invention discloses an exhaust gas after-treatment system 100, which can be applied to treat the exhaust gas of the engine 10 and reduce the emission of harmful substances to meet the requirements of emission regulations. The exhaust aftertreatment system 100 includes an exhaust aftertreatment injection system 200 and an exhaust aftertreatment packaging system 300, wherein the injection system 200 includes a urea solution for pumping from a urea tank 201 (refer to arrow X) and Integrated device 1 for injecting urea solution into the intake or exhaust of the engine 10 (eg into the exhaust pipe 106 or into the packaging system 300 ); the packaging system 300 includes a mixer 301 downstream of the integrated device 1 and a carrier 302 downstream of the mixer 301 . Of course, in some embodiments, no mixer may be provided, or two or more mixers may be provided. The carrier 302 may be, for example, selective catalytic reduction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com