Combined type fin with dovetail sealing grooves

A kind of sealing groove, combined technology, applied in the direction of jet propulsion device, rocket engine device, machine/engine, etc., can solve the problems of a certain amount of shaking, falling off, inconsistent height of the protruding mating surface, etc., so as to prevent the connecting bolt from entering the mating surface. possible, prevent drug leakage, and eliminate potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

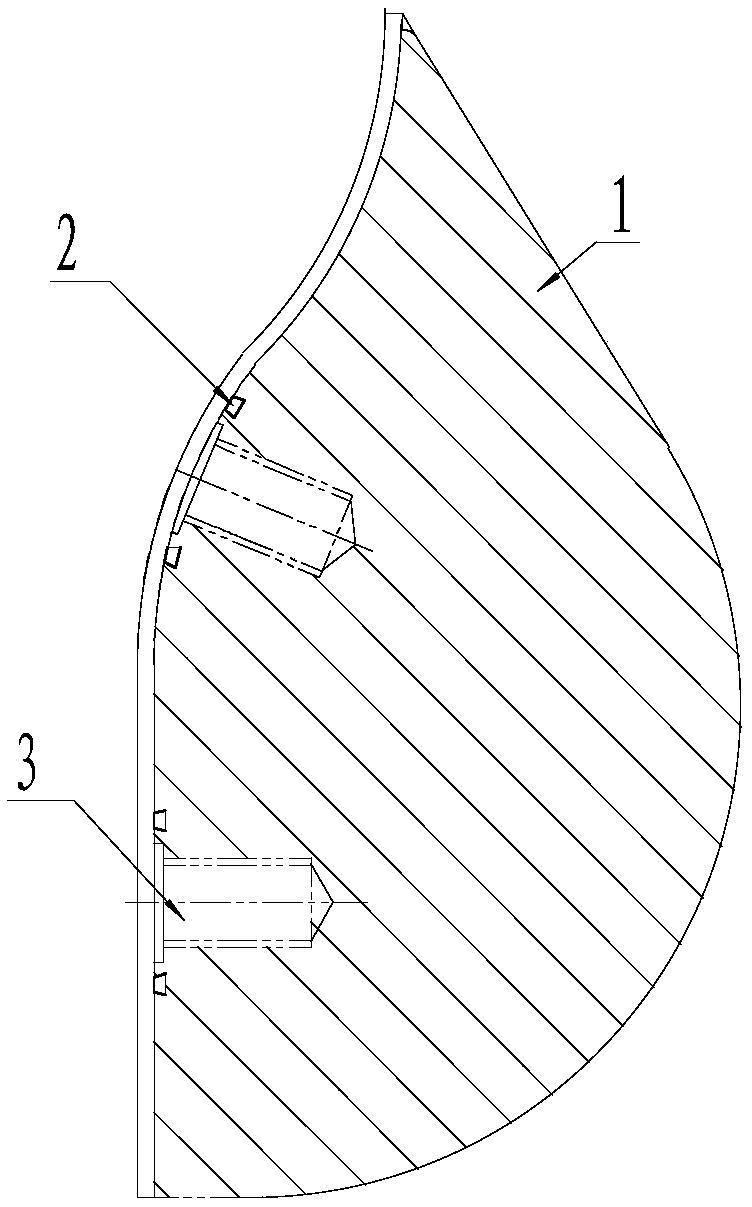

[0017] This embodiment is a combined fin with a dovetail sealing groove.

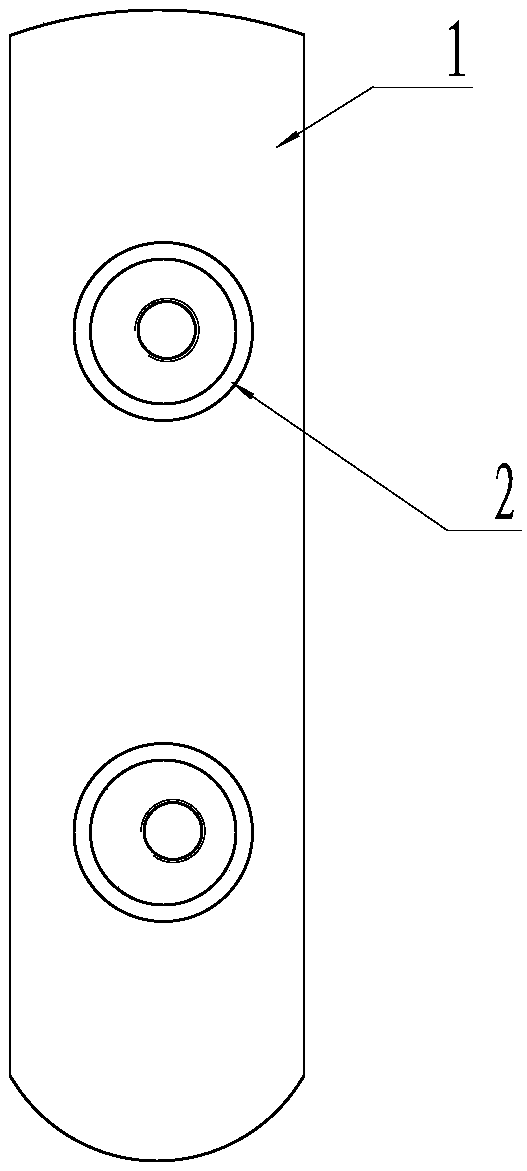

[0018] The mandrel fin 1 is a mandrel head fin of a certain type, and a plurality of fin connecting bolt holes 3 are distributed on the mating surface of the fin and the ferrule of the mandrel assembly head. An annular dovetail seal groove 2 is respectively processed on the outside of the circumference of each fin connecting bolt hole; the diameter of the inner wall of the annular dovetail sealing groove is 2 mm larger than the outer diameter of the fin connecting bolt hole, and the dovetail seal The grooved ring fits over the tab attachment bolt hole, forming a spill-proof barrier over the tab attachment bolt hole.

[0019] The O-ring of silicone rubber is placed in the dovetail seal groove. The width of the bottom of the dovetail sealing groove is larger than the width of the notch; the depth of the dovetail sealing groove is 3.5 mm, and the width of the bottom of the dovetail sealing groove is 4 mm;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com