Furnace body at rubber discharging section of sintering furnace for high-nickel ternary material of lithium battery, and sintering furnace

A high-nickel ternary material and lithium battery technology, applied in furnaces, furnace materials, furnace types, etc., can solve problems such as increasing costs, increasing the load on heating elements, and affecting the lattice structure of products, so as to reduce production costs and improve safety performance , Good degumming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

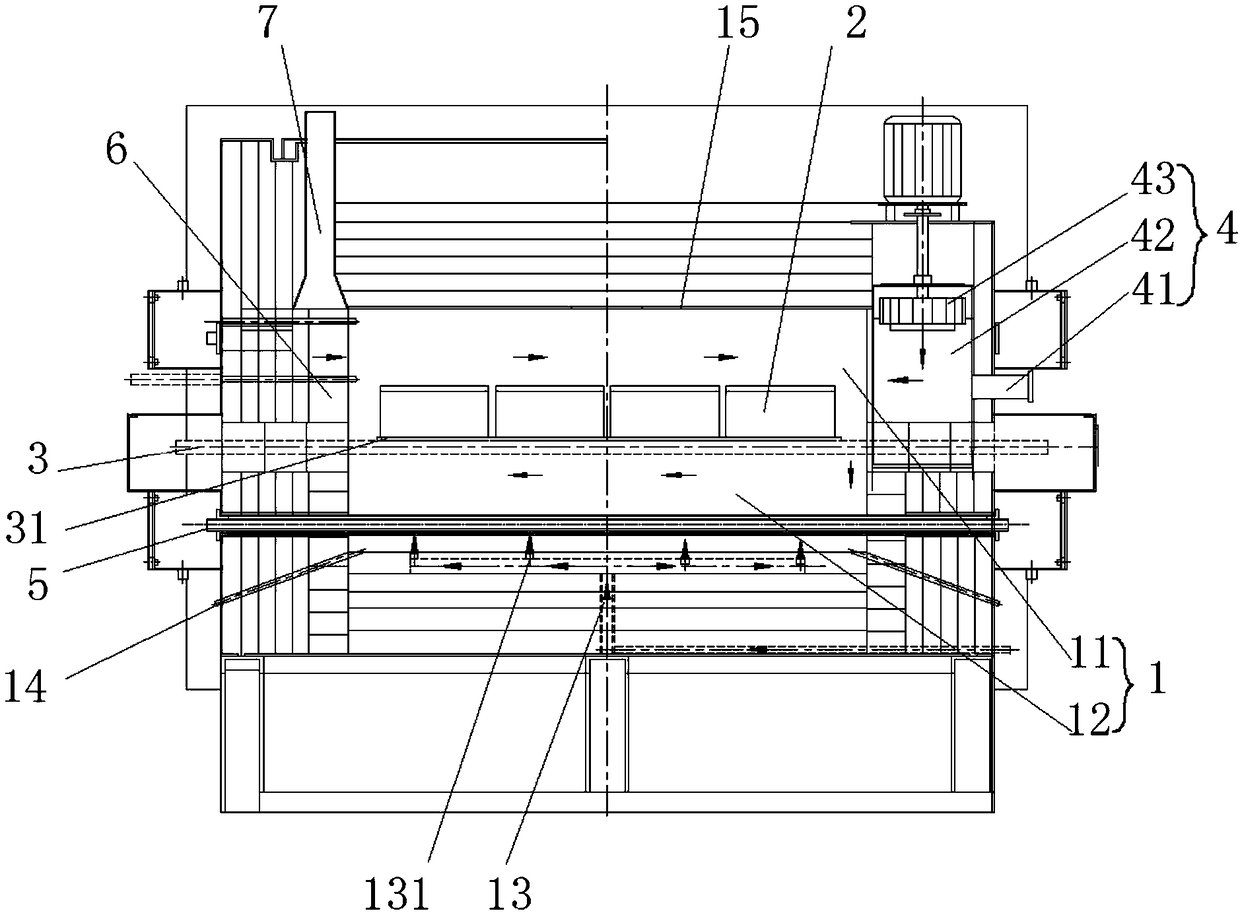

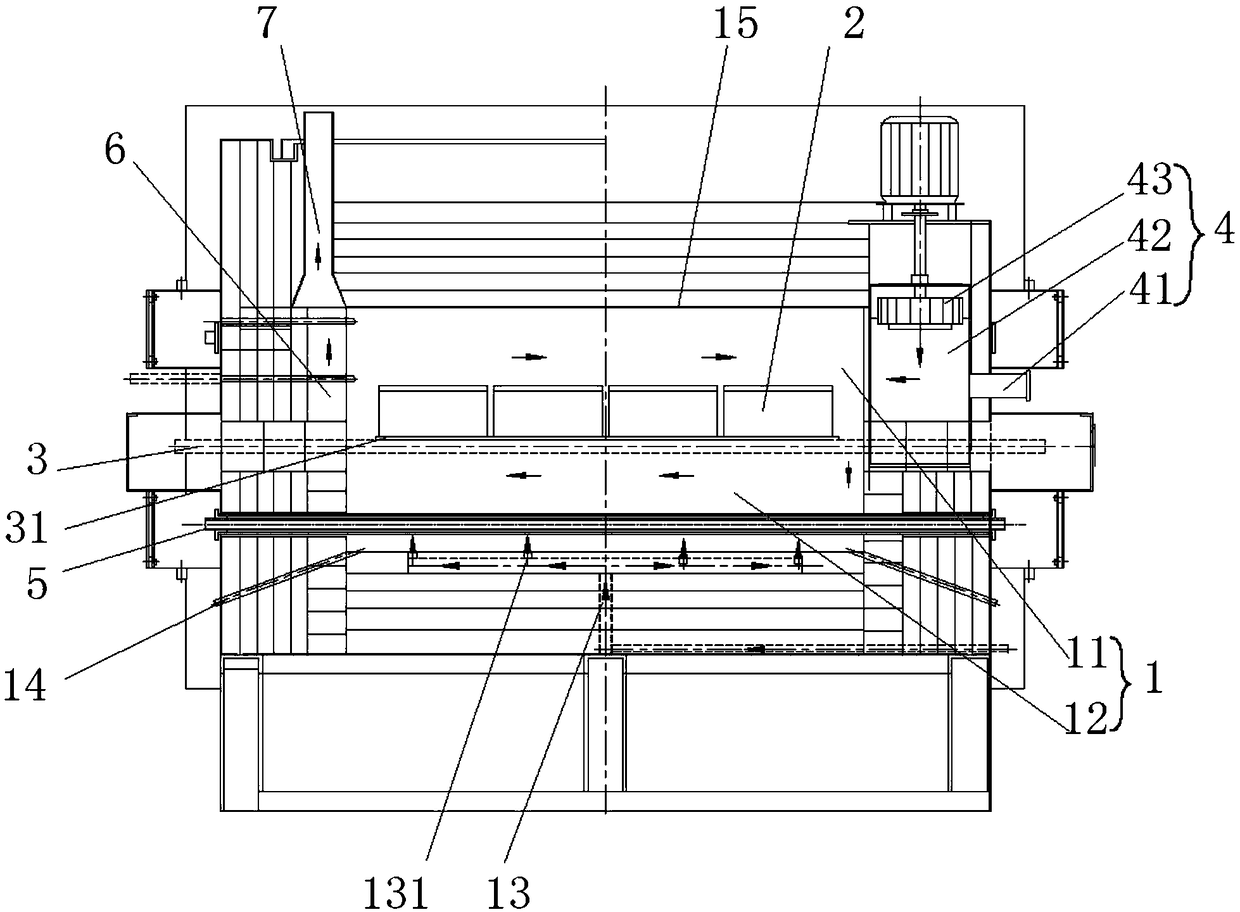

[0031] Such as figure 1 and figure 2 As shown, the furnace body of the high-nickel ternary material sintering grate rubber section of the lithium battery in this embodiment includes a furnace cavity 1, and a stick 3 for transporting the sagger 2 is arranged in the furnace cavity 1, and the stick 3 connects the furnace cavity 1 to Divided into two parts, namely the kiln cavity 11 at the top and the heating cavity 12 at the bottom. The heating element 5 is arranged in the heating cavity 12, the bottom air inlet 13 is arranged at the bottom of the heating cavity 12, and the inlet is installed at one end of the furnace cavity 1. Wind circulation mechanism 4, the other end is provided with bellows 6, and air intake circulation mechanism 4 comprises air inlet cylinder 41, fan seat 42 and circulation fan 43, and fan seat 42 communicates with heating cavity 12, and circulation fan 43 is located at the inside of fan seat 42 In the upper part, one end of the air inlet cylinder 41 face...

Embodiment 2

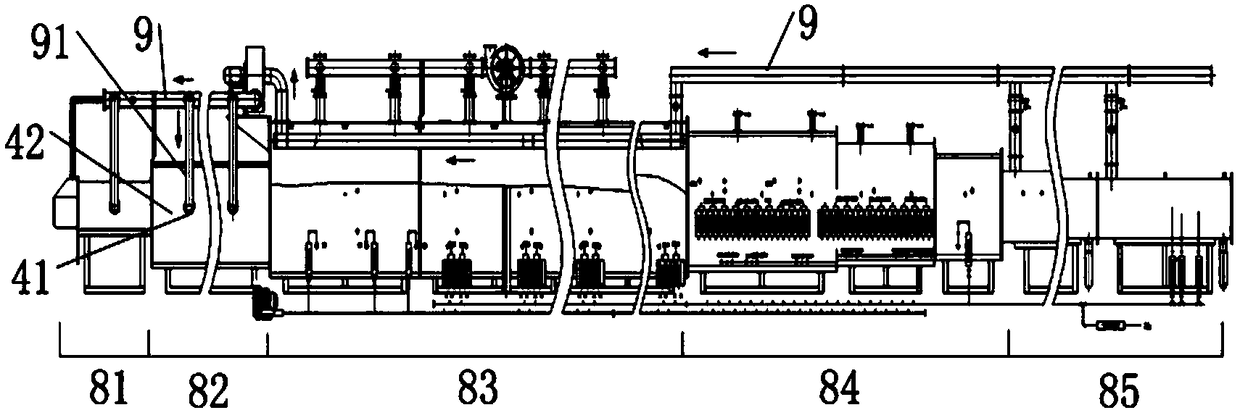

[0040] Such as image 3 As shown, the lithium battery high-nickel ternary material sintering furnace of this embodiment includes a furnace body 81 in a preheating section, a furnace body 82 in a debinding section, a furnace body 83 in a high temperature section, a furnace body 84 in a cooling section, and a furnace body 85 in a cooling section. The furnace body 82 of the debinding section is the furnace body of the debinding section in Embodiment 1, and the air inlet cylinder 41 of the furnace body 82 of the debinding section communicates with the furnace body 84 of the cooling section through the hot air conveying pipe 9 . The hot air delivery pipe 9 is connected with the air inlet cylinder 41 through a branch pipe 91 .

[0041] In this embodiment, the temperature of the hot air exchanged out of the furnace body 84 in the cooling section reaches above 200° C., and is sent back to the furnace body 82 in the debinding section through the hot air conveying pipe 9 to heat the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com