Cylinder liner and Anti-polishing ring

A technology of cylinder liner and wear-resistant ring, applied in the field of wear-resistant ring, can solve the problem of limited service life of pressure sensor, and achieve the effect of increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

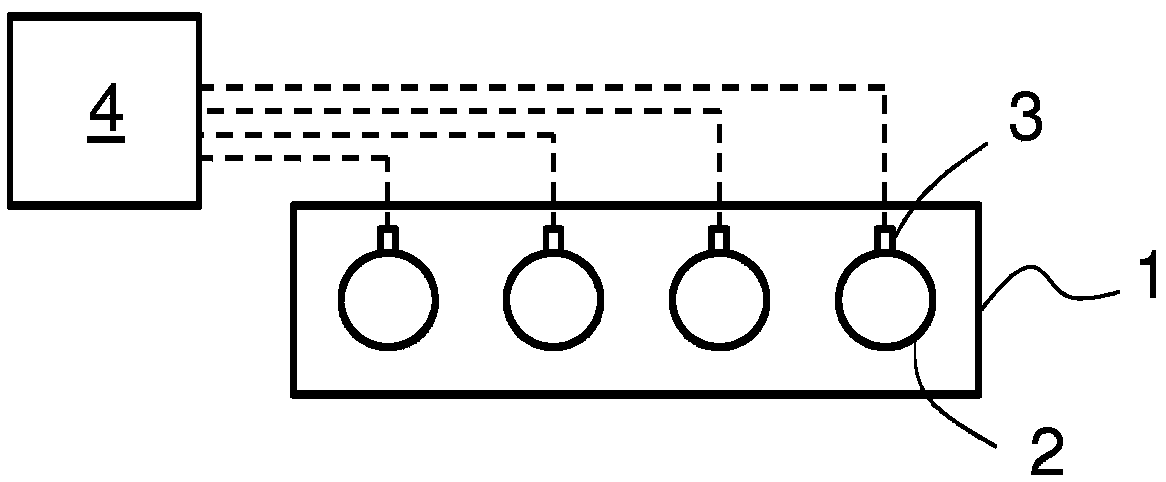

[0015] exist figure 1 An internal combustion engine 1 with a cylinder pressure monitoring arrangement is schematically shown in . The engine 1 is a large piston engine, such as a main or auxiliary engine of a ship or an engine used to generate electricity in a power plant. The cylinder diameter of the engine 1 is at least 150 mm. exist figure 1 , four cylinders 2 are shown. However, the engine 1 may comprise any reasonable number of cylinders 2 which may eg be arranged in line or in a V-shaped configuration. In order to monitor the pressure in the cylinders 2 , each cylinder of the engine 1 is provided with a pressure sensor 3 . The pressure sensor 3 is arranged to directly measure the cylinder pressure. Thus, each pressure sensor 3 is exposed to the cylinder pressure in the corresponding cylinder 2 . Each pressure sensor 3 is connected to a control unit 4 .

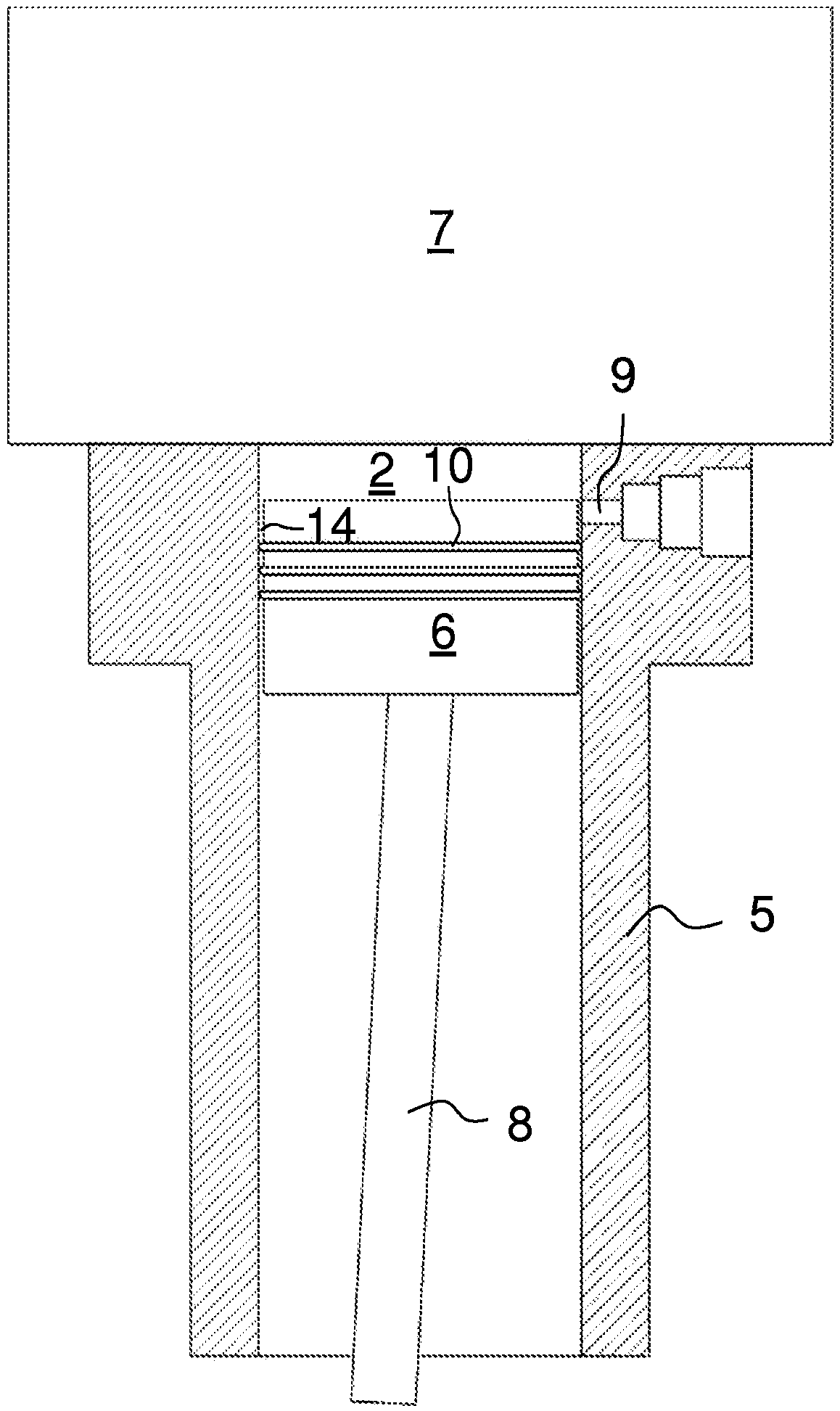

[0016] figure 2 A simplified cross-sectional view of a cylinder liner 5 according to an embodiment of the inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com