Disk type casting molding device

A technology for castings and disks, which is applied in the field of molding production devices for disk castings and molding devices for disk castings, and can solve problems such as easy occurrence of sand holes, casting production efficiency and quality, and difficulty in meeting its requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and embodiments.

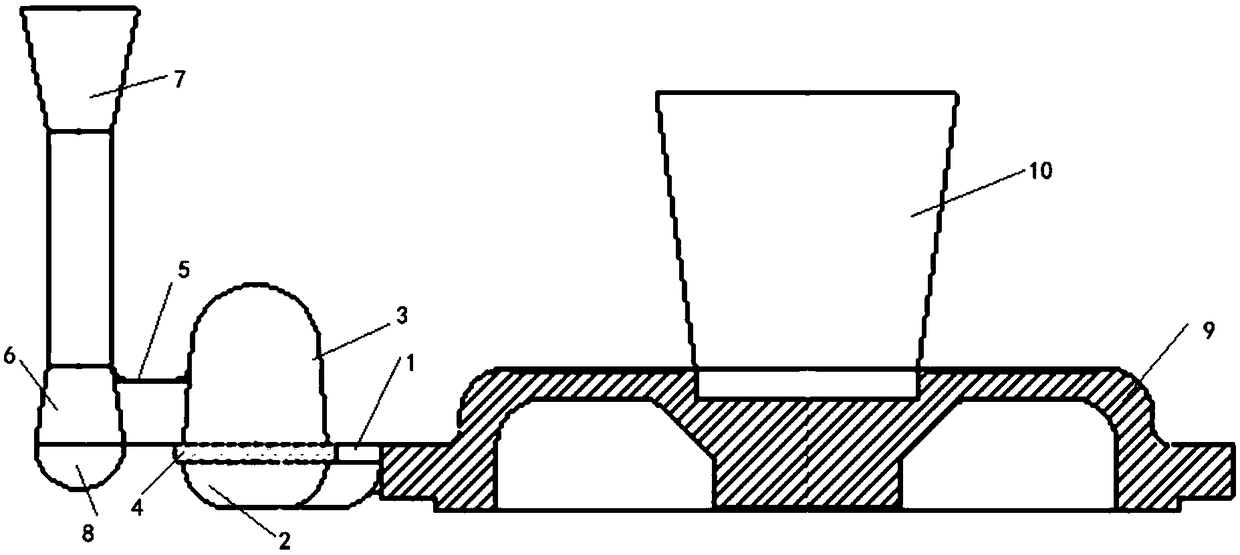

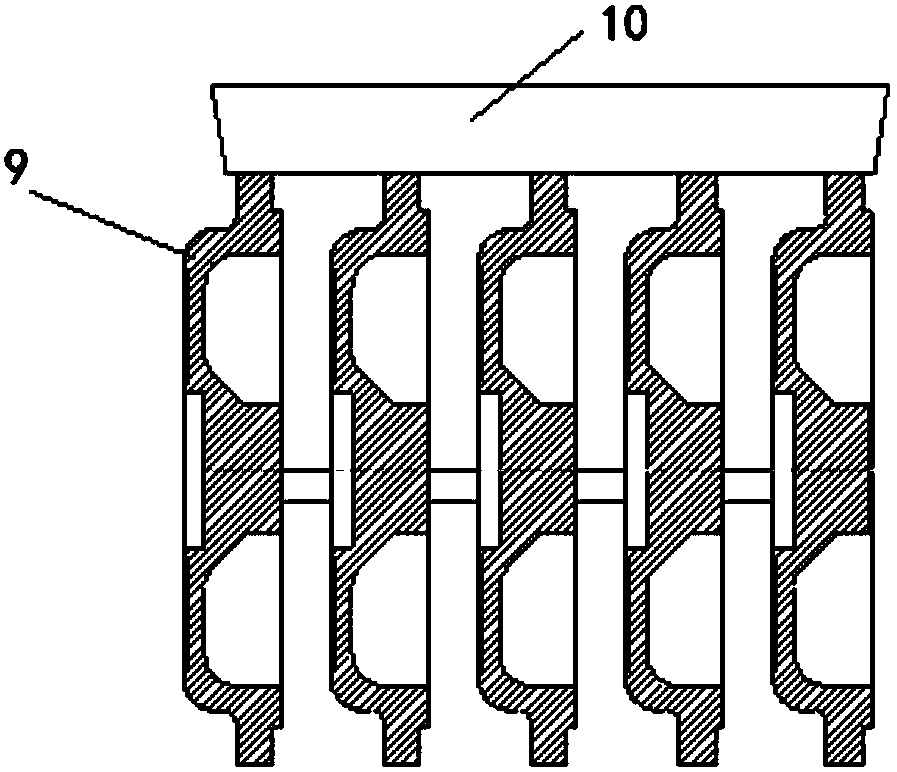

[0020] Such as Figure 1-Figure 2 As shown, the disc casting molding device includes an inner gate 1 communicating with the casting cavity 9 of the disc casting. The top of the casting cavity 9 is provided with an air outlet riser 10 communicating with the inside, which can increase the production rate of the casting process produced by the casting of disc castings, and there will be no sand holes, slag holes, and pores on the top surface of the casting cavity. Surface casting defects, production efficiency and quality can meet its requirements. The air outlet riser 10 is a truncated cone-shaped structure penetrating up and down, and the top of the truncated cone-shaped structure is larger than the bottom. The upper and lower through structure of the truncated cone-shaped structure is also a truncated truncated through-hole structure with the top part larger than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com