A hoisting device for welding and manufacturing high-voltage electrical boxes of EMUs

A hoisting device and electrical box technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems that are difficult to achieve simple, fast, reliable and safe hoisting and disassembly of the welded structure skeleton of the high-voltage box, and achieve simple structure, Improve work efficiency and reduce work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

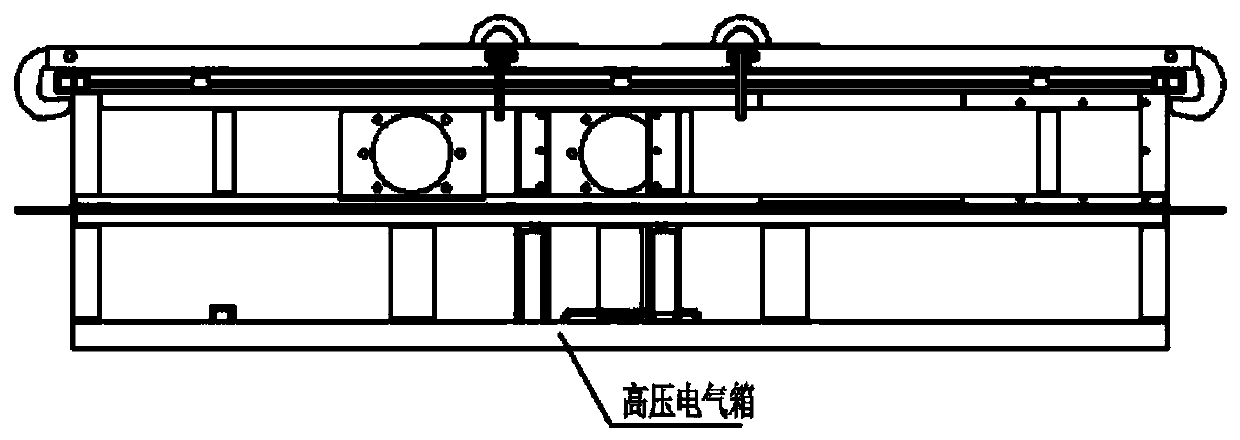

[0014] The hoisting device for the welding manufacture of the high-voltage electrical box of the multiple train set of the present invention, its preferred specific implementation mode is:

[0015] It includes two sets of support arms one set horizontally and two sets of support arms two set vertically. Ribs and lifting lugs are respectively provided at the intersections of the arms, and hooks are respectively provided at the two ends of the first support arm and the second support arm.

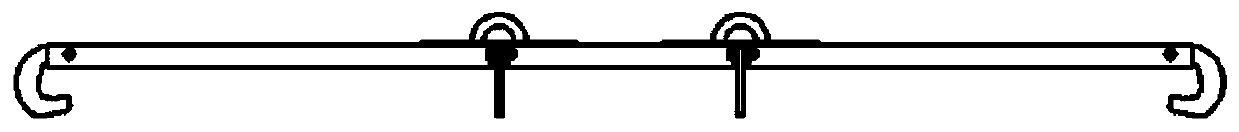

[0016] The two ends of the support arm 1 and the support arm 2 are provided with rotation slots and installation holes, and the hooks are installed in the rotation slots and connected with the installation holes through bolts and nuts.

[0017] The hook is C-shaped, and the hook tips of the hooks at both ends of the same support arm are arranged symmetrically inward.

[0018] The hook is kept in an unlocked state after being rotated outward and upward around the bolt; the hook is kept in a l...

specific Embodiment

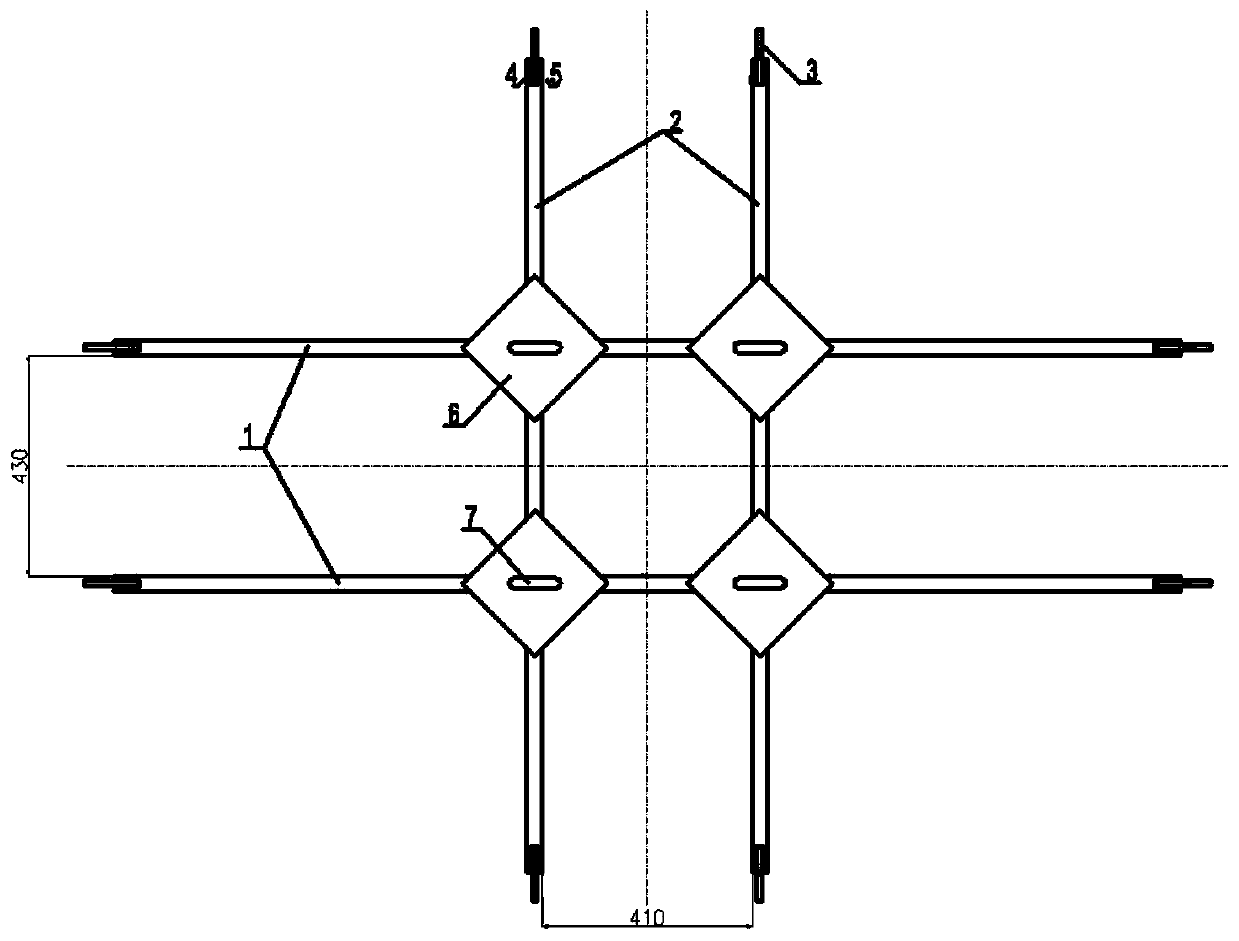

[0022] Specific examples, such as figure 1 , figure 2 , image 3 , Figure 4 Shown:

[0023] The hoisting device for the welding and manufacturing of the high-voltage electrical box of the EMU includes two sets of support arms 1, two sets of support arms 2, eight sets of hooks 3, eight sets of bolts 4 and nuts 5, four sets of ribs 6, and four sets of lifting lugs 7 .

[0024] The support arm-1 adopts a 40mm×30mm×3mm stainless steel rectangular pipe;

[0025] There are 50mm×15mm grooves on the plane with a width of 30mm at both ends; ¢10mm through holes are opened on the sides of 40mm at both ends;

[0026] The support arm two 2 adopts a 40mm×30mm×3mm stainless steel rectangular pipe;

[0027] There are 50mm×15mm grooves on the plane with a width of 30mm at both ends; ¢10mm through holes are opened on the sides of 40mm at both ends;

[0028] The two groups of support arms 1 are parallel to each other; the two groups of support arms 2 are parallel to each other; the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com