A kind of preparation method of trc permanent formwork beam or column

A permanent formwork technology, applied in the preparation of new TRC permanent formwork beams or columns, reinforced concrete beams and columns, can solve the problem of unfavorable ultimate bearing capacity of braided mesh, unspecified formwork production method, excessive natural resources Use and other issues to achieve the effect of promoting construction industrialization, light weight, and easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

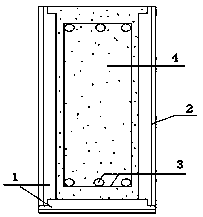

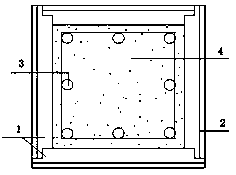

[0042] The preparation method of TRC permanently assembled formwork beams or columns of the present invention uses fiber woven nets and fine concrete to prepare a plurality of TRC veneers 1, and then assembles a plurality of TRC veneers 1 as permanent formwork for pouring beams and columns, and then Pouring the core concrete and curing to the specified conditions, the specific steps are as follows:

[0043] a. Make veneers for TRC permanent assembly templates, such asfigure 2 shown

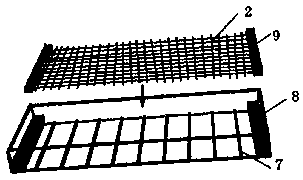

[0044] (1) Determine the size of the TRC veneer 1 and support the wooden formwork. The wooden formwork is a cuboid with one side open. The bottom plate of the wooden formwork is provided with a plurality of corrugated strips 7 at intervals. wooden square 8;

[0045] (2) According to the structural section size of the beam or column and the load-bearing crack limit requi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com