Fuzzy double response surface method for calculating vibration reliability of blade disk

A dual-response and reliability technology, applied in calculation, complex mathematical operations, design optimization/simulation, etc., can solve the problems that the calculation speed and accuracy cannot meet the requirements, and does not consider the correlation of multiple failure modes, etc., to achieve convenient ANSYS analysis functions, reduced computing costs, and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

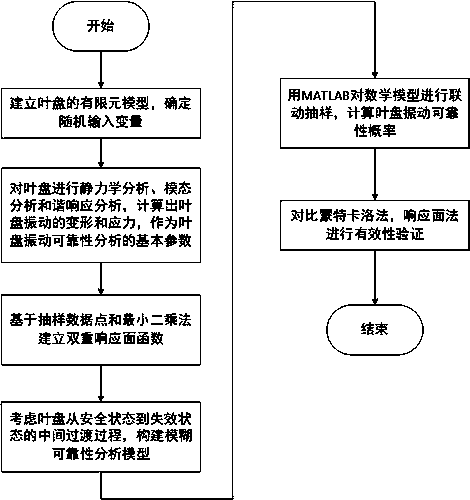

[0030] The multiple response surface method for calculating the vibration reliability of mistuned blisks includes the following steps:

[0031] a. Simulate blade detuning by changing the elastic modulus of each blade;

[0032] b. Determine the basic parameters of the blisk detuning reliability analysis as random input variables;

[0033] c. Analyze the transfer process between fluid-solid coupling loads among the influencing factors;

[0034] d. Under the influence of fluid-solid coupling load, conduct vibration modal analysis and transient response analysis on the blisk to obtain the basic parameters of the blisk vibration reliability analysis;

[0035] e. Constructing the multiple response surface method mathematical model for the reliability analysis of blade disk vibration;

[0036] f. Using the multiple response surface method to analyze the vibration reliability of the blisk;

[0037] g. Verify the effectiveness of the multiple response surface method.

Embodiment 2

[0039] According to the multiple response surface method for calculating the vibration reliability of a mistuned bladed disk described in Embodiment 1, in the step a, the bladed disk structure is divided into hexahedral meshes by using the ABSYS Workbench software.

Embodiment 3

[0041] According to the multiple response surface method for calculating the vibration reliability of mistuned blisks described in Embodiment 1, in the step b, according to the actual working conditions of the blisks of the engine, the external load factors and the structural performance of the blisks that affect the reliability of the blisks are determined. parameter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com