A Venturi Mixer Containing Porous Annular Cavity and Its Application in Synthesis of Cyanohydrin

A Venturi mixer and annular cavity technology, which is applied in fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of high mainstream fluid flow rate, uneven mixing, and low mixing efficiency, and achieve high uniformity. Mixing degree, improve mixing effect, improve the effect of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 A kind of Venturi mixer containing porous annular cavity

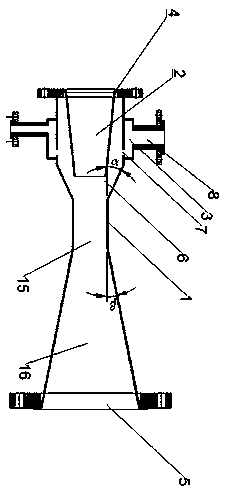

[0043] The structure of the Venturi mixer is as figure 1 shown;

[0044] The Venturi mixer comprises a housing 1, a nozzle 2 arranged in the housing and an annular cavity 3 outside the housing;

[0045] The main fluid inlet 4 and the mixed fluid outlet 5 are respectively provided at both ends of the housing 1;

[0046] The constriction section 6 behind the outlet of the nozzle 2 is the mixed area of the main fluid and the incoming fluid;

[0047] The annular chamber 3 is located outside the housing 1, and communicates with the interior of the housing 1 through the flow hole 7 on the housing 1; the vertical height of the upper surface of the annular chamber 3 from the Venturi mixer housing 1 is smaller than the inner diameter of the branch pipe 8 , the annular cavity 3 is located between the inlet and the outlet of the nozzle 2 and before the constriction section 6 .

[0048] The flow hole 7 is l...

Embodiment 2

[0056] Embodiment 2 Application of Venturi mixer in the synthesis of 3-methylthiopropionaldehyde

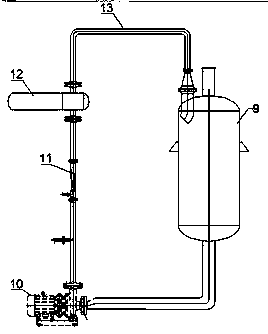

[0057] The reaction device for synthesizing 3-methylthiopropionaldehyde is as image 3 As shown, it is mainly composed of a reactor 9, a circulation pump 10, a Venturi mixer 11, a heat exchanger 12 and a mother liquor circulation pipeline 13.

[0058] The operating process of the reaction device for the synthesis of 3-methylthiopropionaldehyde of the present invention is that the methylmercaptan pipeline is directly introduced into the Venturi mixer 11 to mix with the mother liquor, and the circulation pump 10 provides the power of the forced circulation loop, and the methylmercaptan and the mother liquor Continue to mix in the mother liquid circulation line 13, then enter the reactor 9 for reaction, and the heat exchanger 12 takes away the heat generated by the reaction.

[0059] The diameter of the mother liquid circulation pipeline 13 is 350mm, the diameter of the Venturi mai...

Embodiment 3

[0062] Application of embodiment 3 Venturi mixer in cyanohydrin preparation process

[0063] In another form of the present invention, 3-methylthiopropionaldehyde is mixed with hydrogen cyanide gas to react to generate cyanohydrin. Hydrocyanic acid gas enters from the branch pipe. The diameter of the branch pipe 8 is 50 mm, and four flow holes 7 with a diameter of 10 mm are evenly distributed on the circumference, connecting the annular cavity 3 and the inside of the Venturi tube shell. The outlet diameter of the nozzle 2 is 65 mm, the diameter of the mixing chamber 15 is 89 mm, and the length is 230 mm.

[0064] All the other parameters are the same as in Example 2.

[0065] In order to test the mixing effect of the Venturi mixer, CFD simulation was carried out on the Venturi tube. The simulation results show that the main fluid flow rate is 1200m with the addition of the Venturi tube in the annular cavity 3 / h, the overall pressure drop is 0.44MPa, the degree of mixing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com