Fish mouth sealing structure between turbine rotor and stator of gas turbine

A gas turbine and turbine rotor technology, applied to mechanical equipment, engine components, machines/engines, etc., can solve problems such as increased thermal stress, complex fish mouth sealing structure, and increased process difficulty, so as to reduce thermal stress and improve sealing Strict effect, the effect of reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solutions and advantages of the present invention clearer, the invention will be further described in detail below in conjunction with specific examples. The following examples are explanations of the present invention, and the present invention is not limited to the following examples.

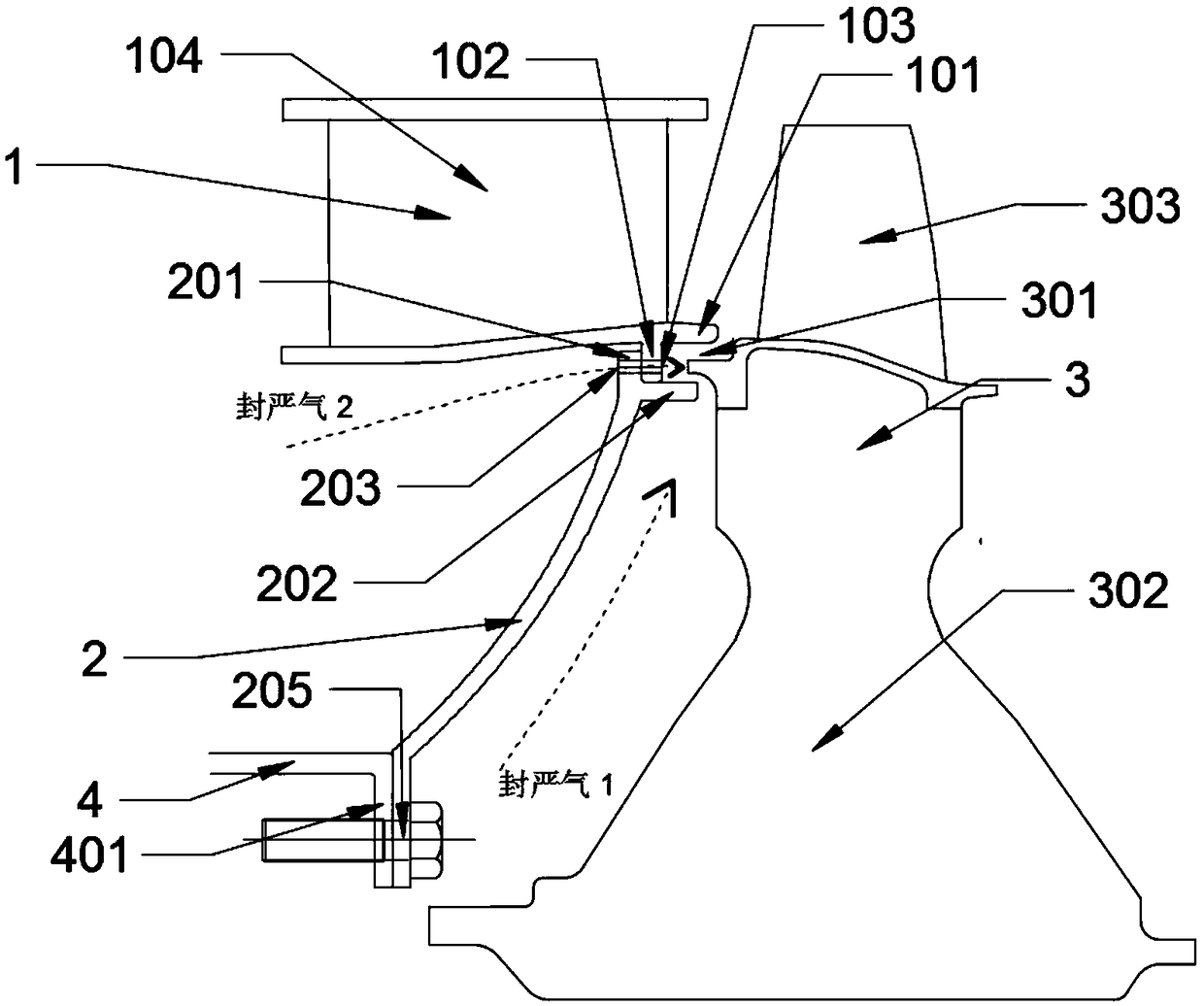

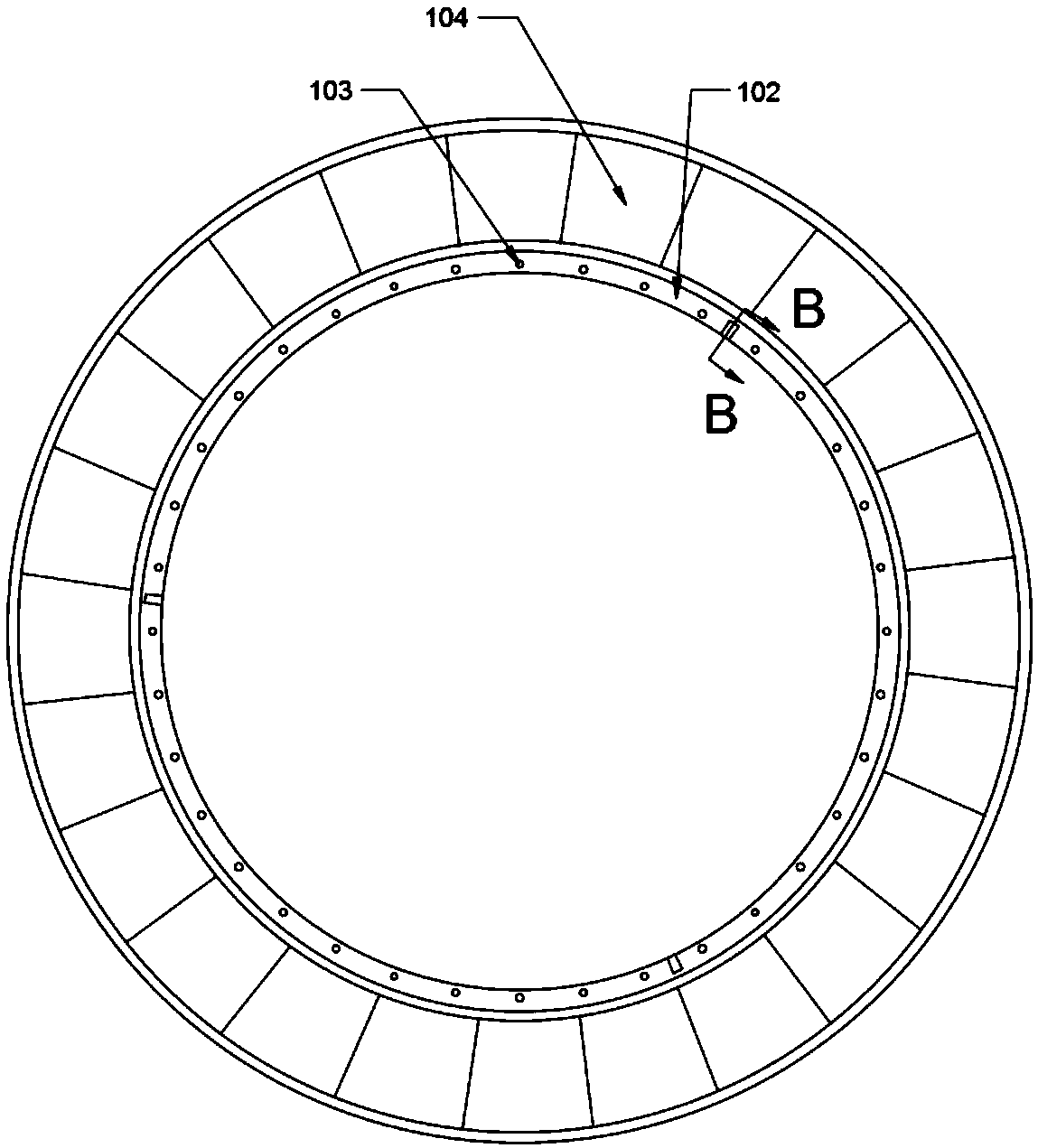

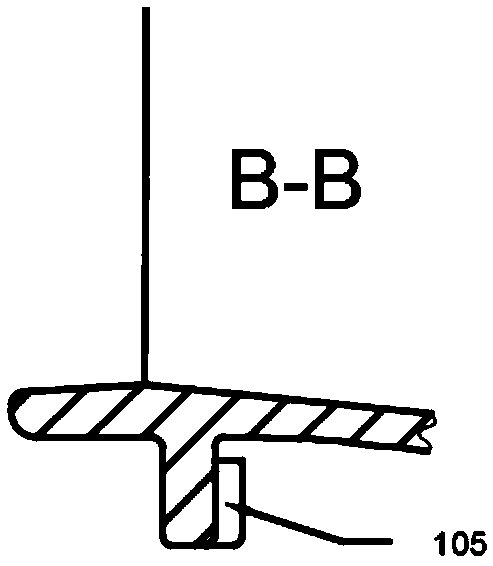

[0030] Such as figure 1 As shown, the high-pressure turbine interstage fish mouth sealing structure of the gas turbine of the present invention includes a high-pressure turbine guide 1 , an auxiliary fish mouth sealing cone 2 , a high-pressure turbine rotor 3 and a stator casing 4 . Such as Figure 1~3 As shown, the high-pressure turbine guide 1 includes a plurality of high-pressure turbine guide blades 104 distributed along its circumference, a high-pressure turbine guide inner ring outlet wall surface 101, a high-pressure turbine guide outlet installation edge 102, a high-pressure turbine guide outlet installation edge Seal the hole 103 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com