Method for solving problem of SO2 poisoning of low-temperature SCR denitration catalyst

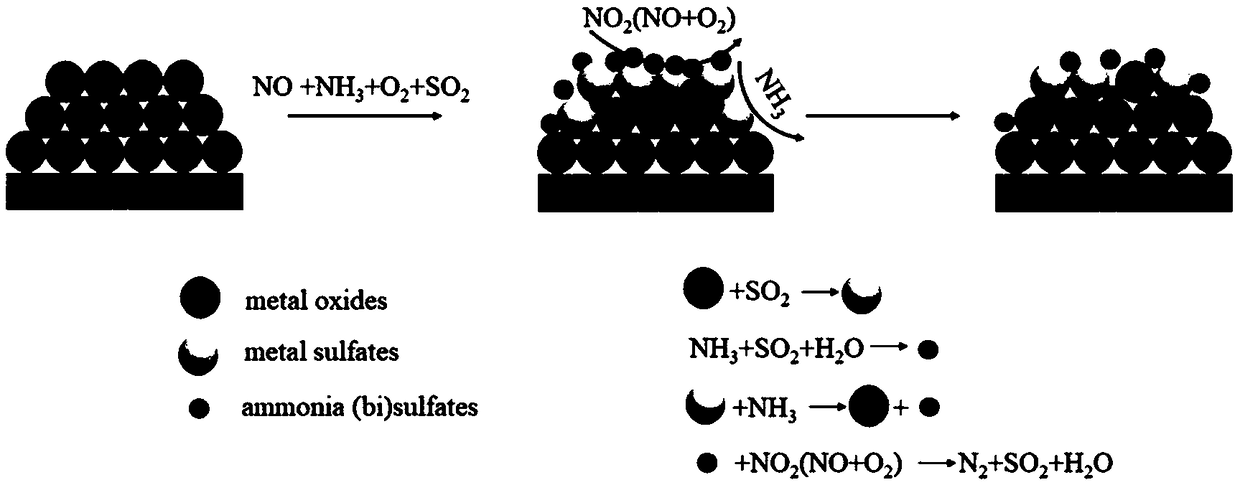

A denitrification catalyst, catalyst technology, applied in the direction of chemical instruments and methods, catalyst regeneration/reactivation, physical/chemical process catalysts, etc., can solve the problems such as the difficulty of suppressing the formation of sulfate on the surface of the catalyst, unresolved problems, and catalyst poisoning. Achieve the effect of reducing operating costs, prolonging service life, and restoring active components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

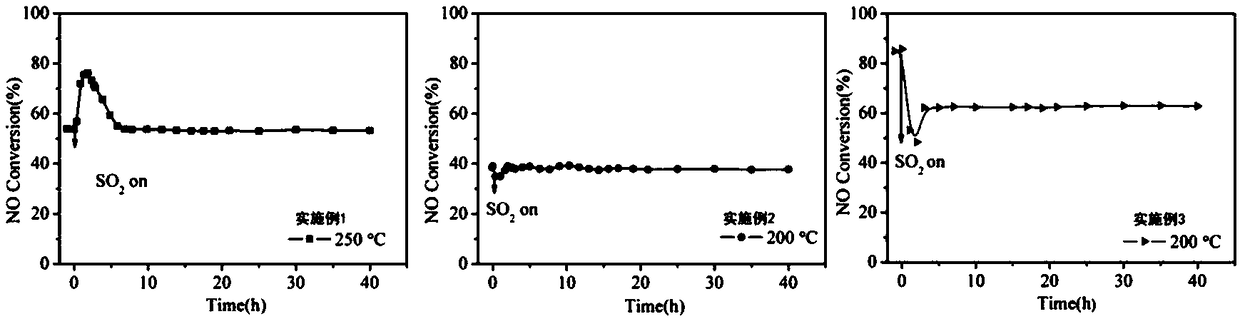

Embodiment 1

[0021] With CeO 2 It is a low temperature denitrification catalyst, 800ppm NO, 800ppm NH 3 , 200ppm SO 2 , 5vol%O 2 , Ar is the balance gas, the gas flow rate is 500ml / min, and the reaction temperature is 250°C. The performance of the denitrification test catalyst first increased and then decreased in the first 5 hours, and remained unchanged at 53% in the final 40 hours.

Embodiment 2

[0023] With CeO 2 It is a low temperature denitrification catalyst, 800ppm NO, 800ppm NH 3 , 200ppm SO 2 , 5vol%O 2 , Ar is the balance gas, the gas flow rate is 500ml / min, and the reaction temperature is 200°C. The performance of the denitrification test catalyst remained unchanged at 38% within 40 hours.

Embodiment 3

[0025] MnO X / CeO 2 (MnO X loading is 3wt%) as catalyst, 800ppm NO, 800ppm NH 3 , 200ppm SO 2 , 10vol%O 2 , Ar is the balance gas, the gas flow rate is 500ml / min, and the reaction temperature is 200°C. The performance of the denitrification test catalyst in SO 2 It remained constant at 63% from 3 hours to 40 hours of infusion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| oxidation efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com