High dimensional model 3D printer and 3D printing method

A 3D printer and 3D printing technology, applied in the field of 3D printing, can solve the problems of low printing accuracy, prone to defective products, large errors, etc., and achieve the effect of compact structure and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

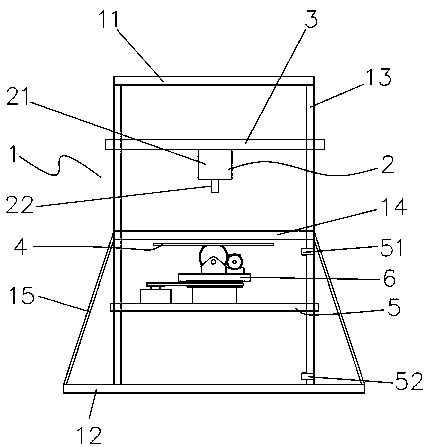

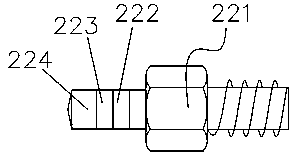

[0021] Such as Figure 1-4 As shown, a high-size model 3D printer of the present invention includes a frame 1 , a printing head 2 , a moving support assembly 3 and a material receiving tray 4 . The mobile bracket assembly 3 is installed on the top of the frame 1 and can drive the print head 2 to move up and down, left and right. The frame 1 is composed of an upper frame 11, a lower frame 12 and a column 13 connecting the upper and lower frames. The horizontal reinforcing link 14 is also connected with an oblique support rod 15 between the middle of the column of the frame 1 and the lower frame 12 .

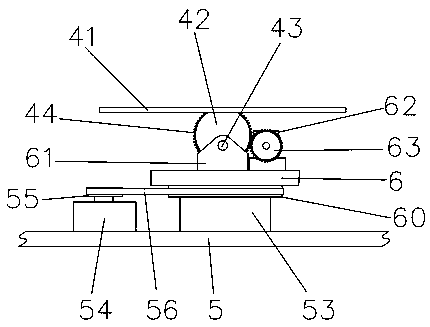

[0022] A liftable support 5 is installed below the reinforcing link 14 on the frame 1 , and an upper limit switch 51 and a lower limit switch 52 that the liftable support 5 moves are installed on the column 13 . On the liftable support 5, a turntable 6 is installed by a bearing seat 53, a driven pulley 60 is installed on the bottom surface of the turntable 6, a stepper motor 54 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com