Novel anti-stick rubber roller

A rubber roller and anti-sticking technology, applied in printing, printing devices, typewriters, etc., to achieve the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

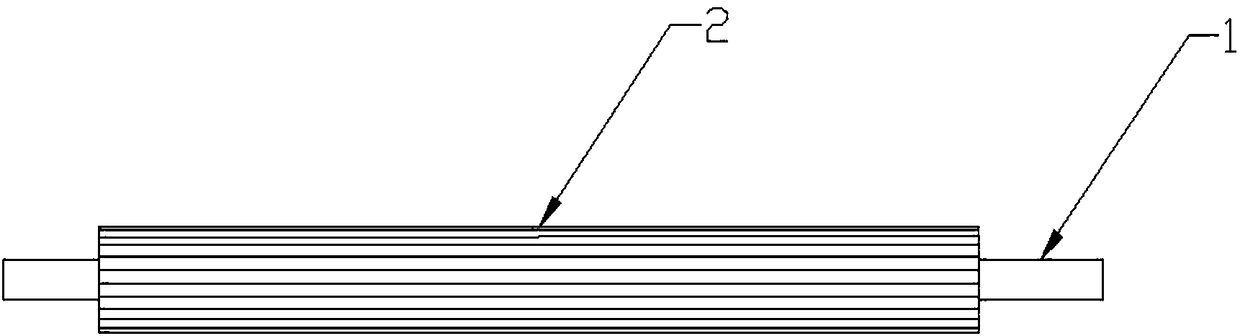

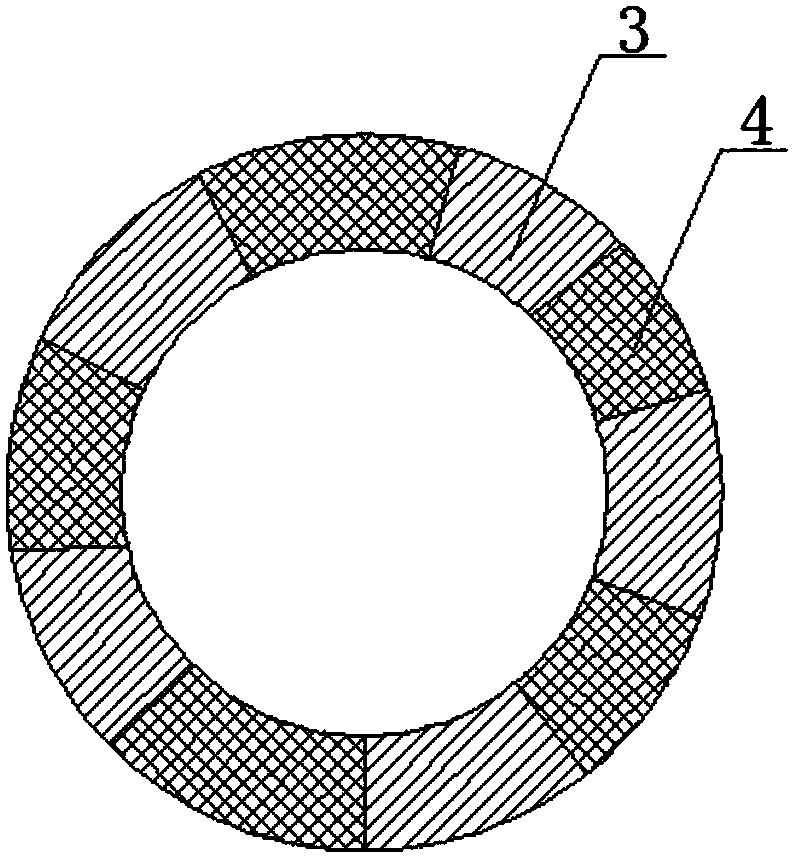

[0019] A new type of anti-sticking rubber roller, such as figure 2 and image 3 As shown, it includes a roller shaft 1 and a coating layer 2. The coating layer is coaxially wrapped around the outer edge of the roller shaft. The outer surface; The rubber can be any one of natural rubber, nitrile rubber and polyurethane rubber;

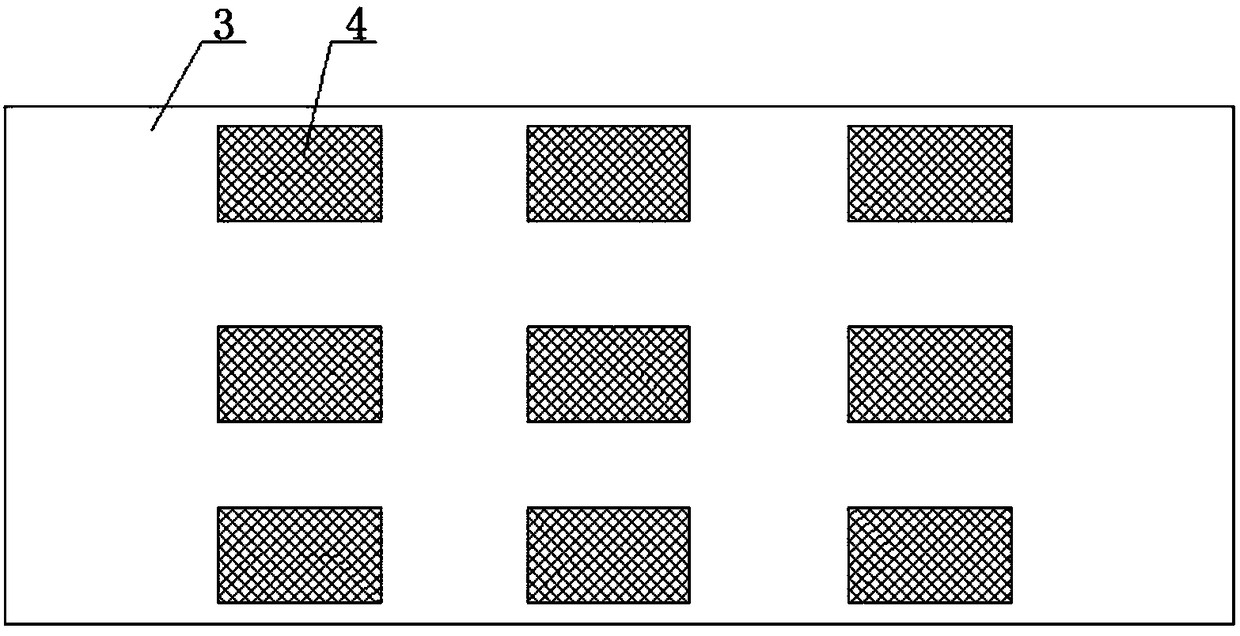

[0020] There are two ways to alternate: one such as image 3 As shown, the rubber strips 4 and the silicone rubber strips 3 are arranged at intervals and pasted on the outer surface of the roller shaft, and the other is that the rubber blocks are embedded on the outer surface of the silicone rubber coating layer at intervals, and the surface is smooth.

[0021] The silicone rubber is added with polymethylvinylsilsesquioxane spherical micropowder in the silicon mixing silicone rubber, and the surface of the vulcanized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com