Method for emulsifying dioctyl sebacate

A dioctyl sebacate, non-ionic technology, applied in the field of polymer compound processing, can solve the problem that dioctyl sebacate cannot be directly added to natural latex, etc., and achieves obvious plasticizing effect and good compatibility. , The effect of product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

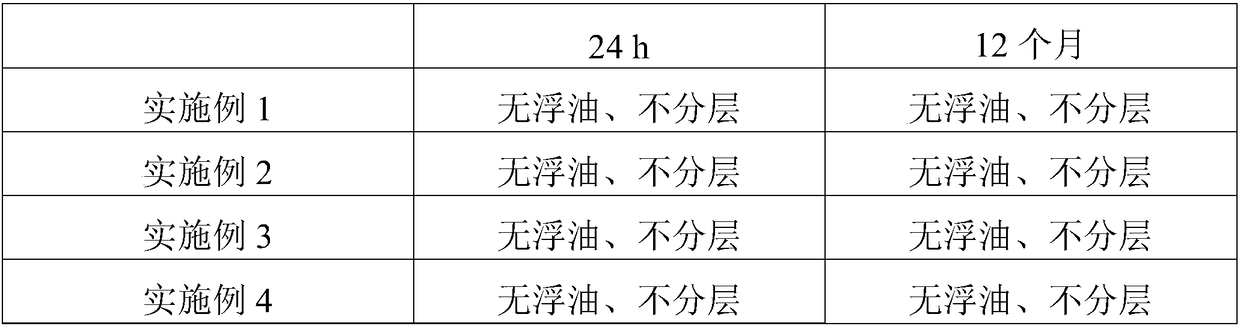

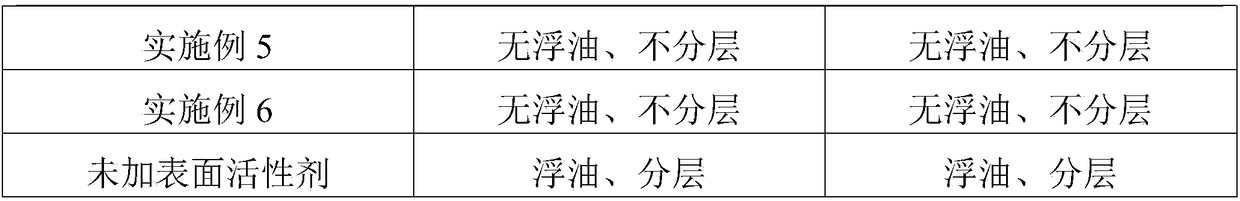

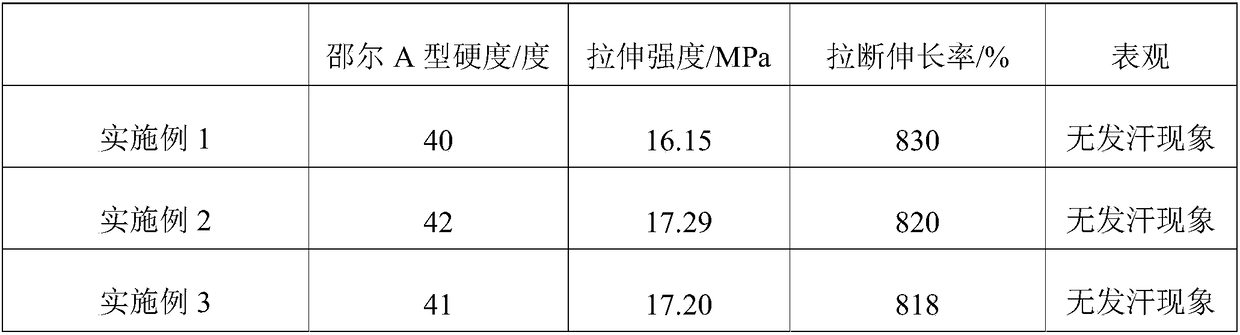

Examples

Embodiment 1

[0019] Sequentially add dioctyl sebacate and non-ionic surfactant into the stirring tank, heat to 75°C, stir for 10 minutes to dissolve, and the rotation speed is 2000r / min. After dissolving, keep the rotation speed constant, add pure water at 30°C while stirring at room temperature, so that the mass fraction of dioctyl sebacate is 25%, and complete the addition within 3-5 minutes. Then continue to stir for 80min to successfully emulsify dioctyl sebacate. Wherein, the mass ratio of dioctyl sebacate and nonionic surfactant is 4:1, and described nonionic surfactant is the mixture of Span 60 and Tween 60, the mixture of Span 60 and Tween 60 The mass ratio is 0.45:0.55.

Embodiment 2

[0021] Sequentially add dioctyl sebacate and non-ionic surfactant into the stirring tank, heat to 80°C, stir for 10 minutes to dissolve, and the rotation speed is 3500r / min. After dissolving, keep the rotation speed constant, add pure water at 35°C while stirring at room temperature, so that the mass fraction of dioctyl sebacate is 40%, and complete the addition within 3-5 minutes. Stirring was then continued for 90 minutes to successfully emulsify dioctyl sebacate. Wherein, the mass ratio of dioctyl sebacate and nonionic surfactant is 3:1, and described nonionic surfactant is the mixture of Span 60 and Tween 60, the mixture of Span 60 and Tween 60 The mass ratio is 0.45:0.55.

Embodiment 3

[0023] Sequentially add dioctyl sebacate and non-ionic surfactant into the stirring tank, heat at 60°C, stir for 5 minutes to dissolve, and the rotation speed is 500r / min. After dissolving, keep the rotation speed constant, add pure water at 25°C while stirring at room temperature, so that the mass fraction of dioctyl sebacate is 20%, and complete the addition within 3 minutes to 5 minutes. Then continue to stir for 60 minutes to successfully emulsify dioctyl sebacate. Wherein the mass ratio of dioctyl sebacate and nonionic surfactant is 5:1, and described nonionic surfactant is the mixture of Span 60 and Tween 60, the quality of Span 60 and Tween 60 The ratio is 0.3:0.7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com