Method and system for optimizing top cycle oil flow rate of catalytic cracking fractionating tower during gasoline and diesel cutting process

A technology for catalytic cracking and topping cycle oil, which is applied in the distillation control/regulation of hydrocarbon oil, general control system, control/regulation system, etc., can solve the problem of excessive gasoline dry point, increase the flow rate of topping cycle oil, and fail to improve benefits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

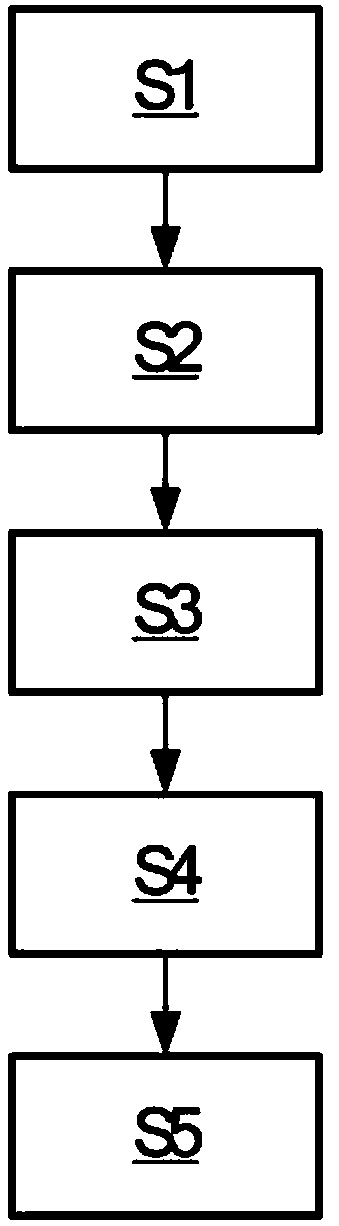

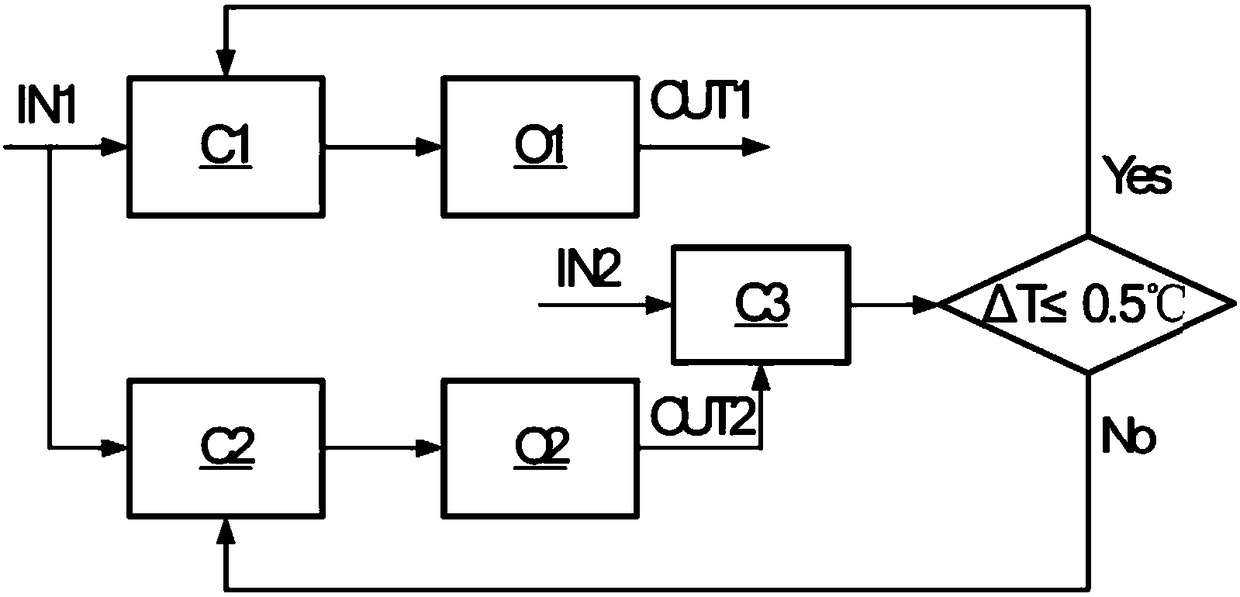

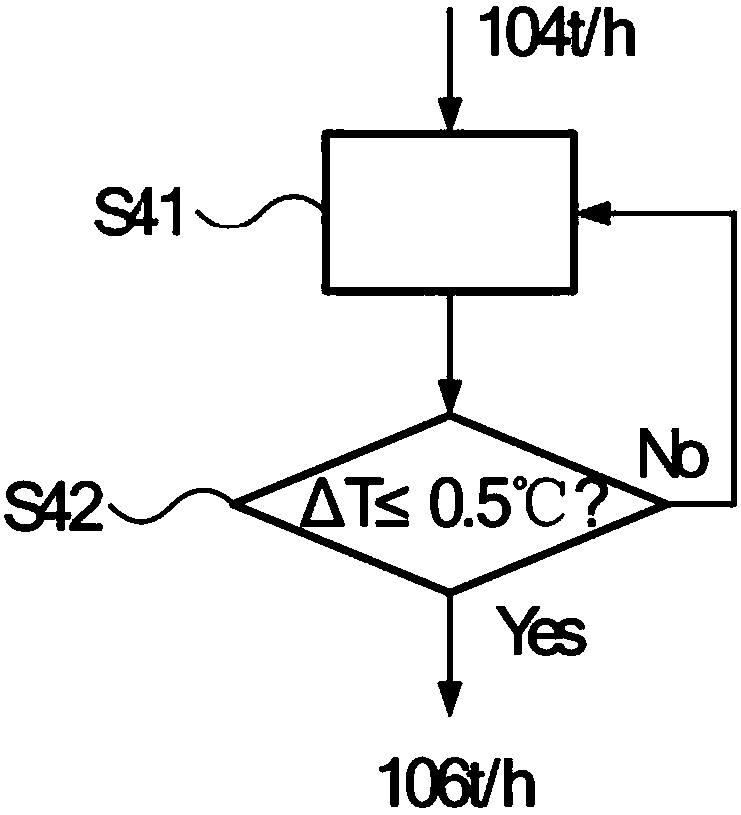

[0066] According to the present invention, the SIMIT simulation framework is used to build a dynamic model of the catalytic cracking fractionation tower, and at the same time, compared with the actual device, the dynamic model model of the catalytic cracking fractionation tower is corrected. Configure on the SIMATIC PCS7 platform to create the control environment of the distributed control system. Through graphical configuration, the computer control process of the actual industrial device is completely imitated with a realistic virtual environment, and a distributed control system simulator is established to control the catalyst The distributed control system of the gasoline and diesel cutting process of the cracking fractionation tower is simulated. Therefore, SIMIT and PCS 7 were used to establish a full-tower simulation system for the catalytic cracking fractionation tower, and to perform simulation control and global optimization of the entire catalytic cracking unit. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com