Anti-vibration and shock transformer

A transformer and anti-vibration technology, which is applied in the field of transformers, can solve problems such as easy to break PCB board wiring, inability to buffer shocks, and damage to plastic shells, so as to prevent cracking of the internal glue of the transformer and damage to components, and improve the resistance Vibration and shock performance, the effect of increasing the effective length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

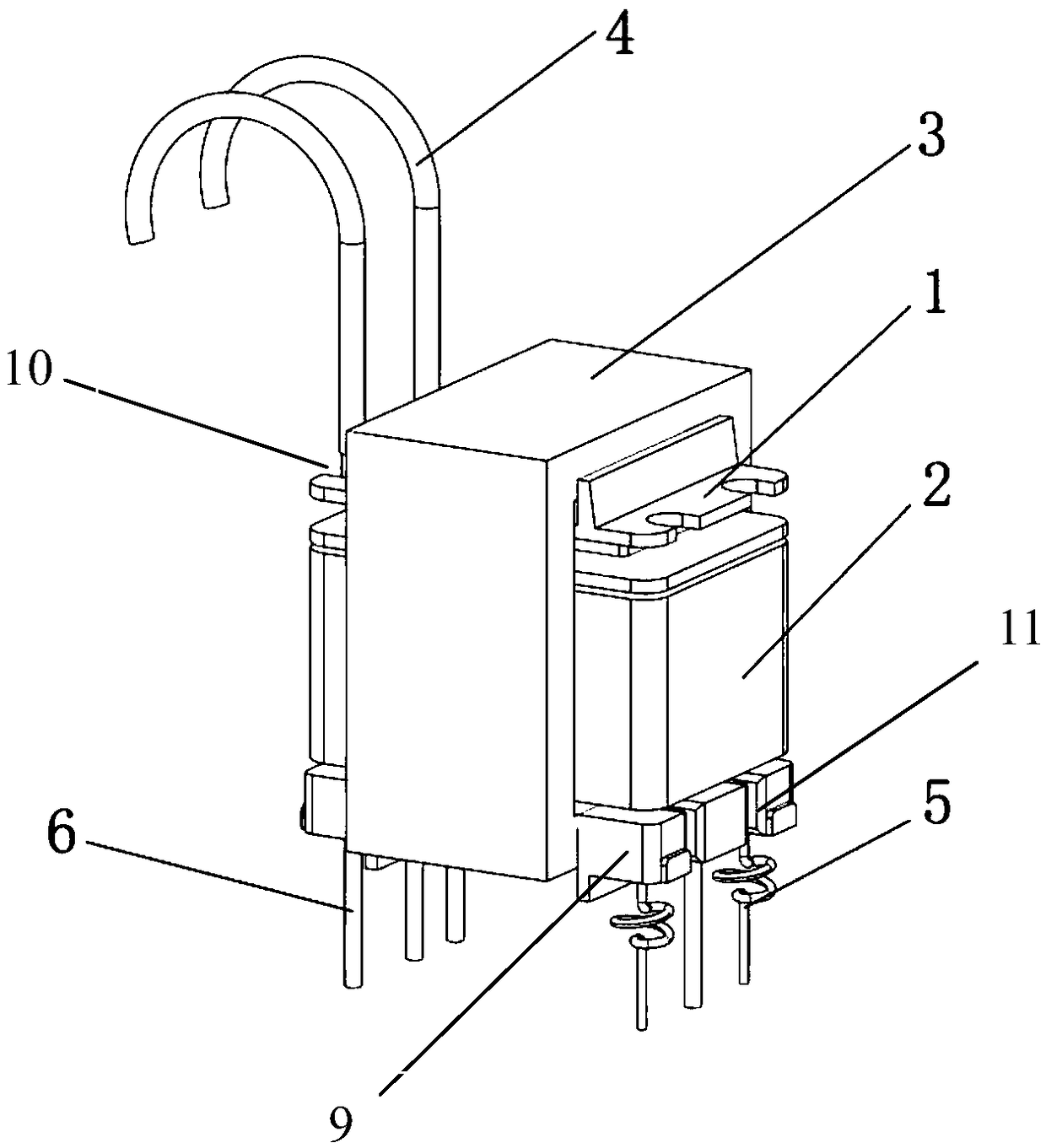

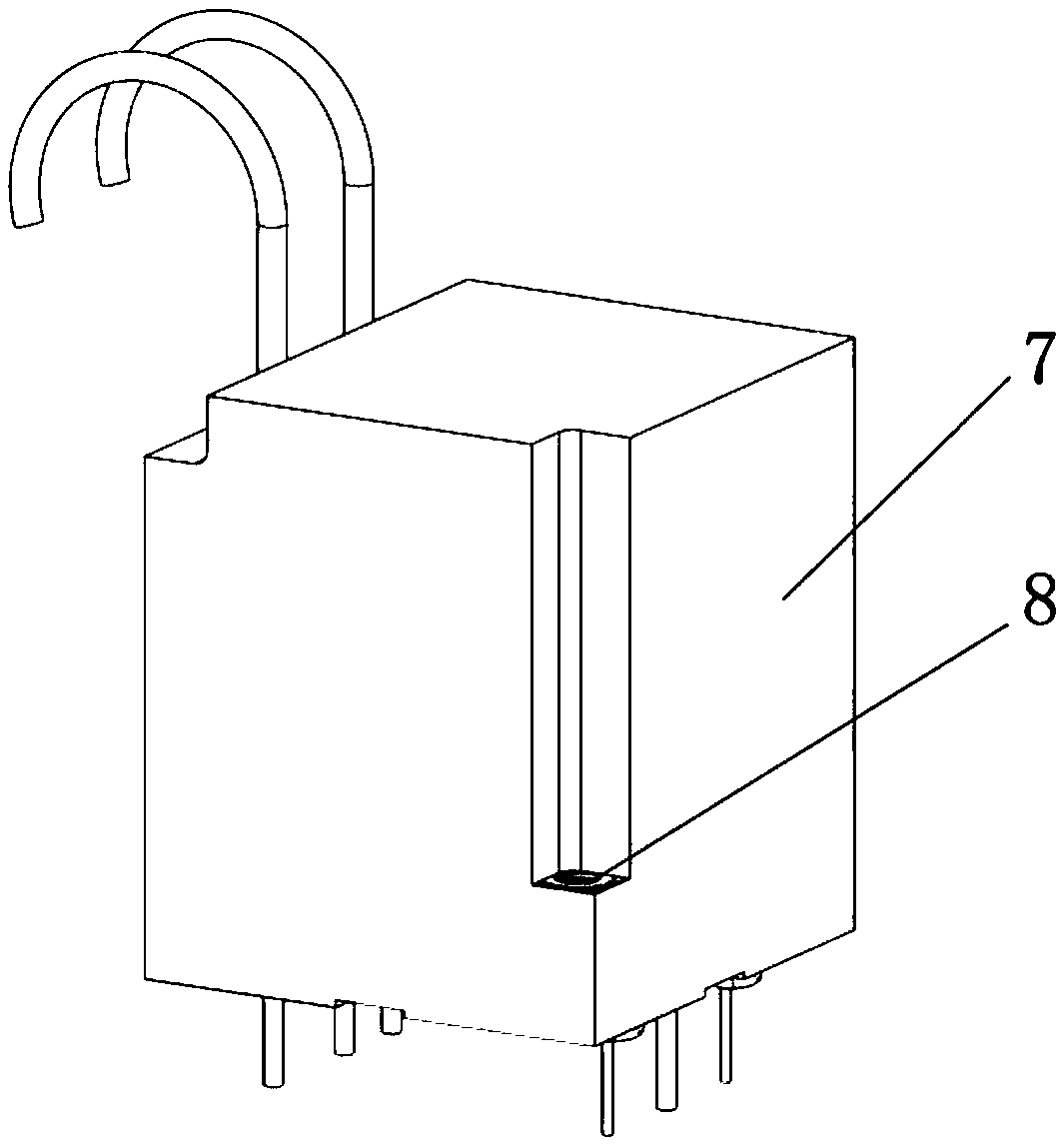

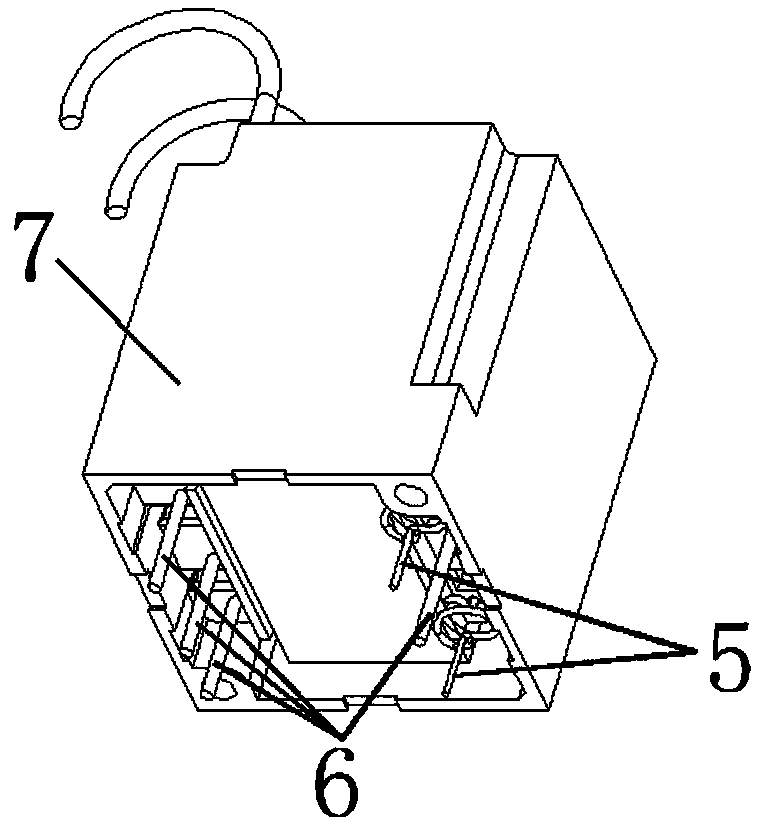

[0019] Such as Figure 1 to Figure 3 Shown is a specific technical solution of the present invention. The picture shows the welded transformer with the upper incoming wire. The transformer structure includes a frame, a coil 2, a silicon steel sheet group 3, a primary lead 4, a secondary lead 5, a fixed pin 6, a plastic shell 7, and a nut 8 embedded in the shell.

[0020] Such as Figure 1 to Figure 3 As shown, the skeleton includes an upper skeleton 1 and a lower skeleton 9, the coil 2 is located between the upper skeleton 1 and the lower skeleton 9, and both the upper skeleton 1 and the lower skeleton 9 are located in the hollow space of the silicon steel sheet group 3. It also includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com