Intelligent monitoring terminal, control method and monitoring system for oil engines of base stations

A technology of intelligent monitoring and base station oil generators, applied in information technology support systems, electrical components, circuit devices, etc., can solve problems such as difficult management, high cost, and wide distribution of base station oil generators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

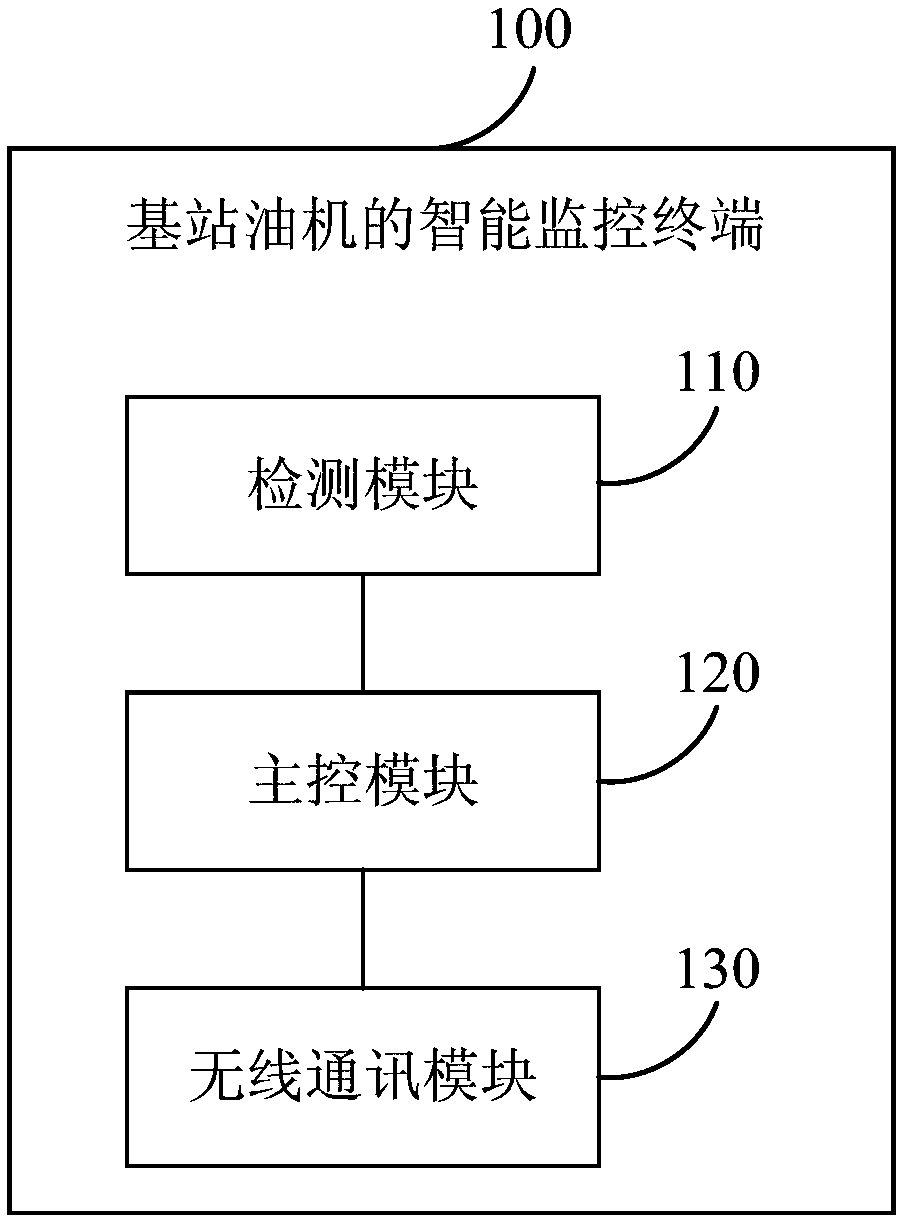

[0024] figure 1 Embodiment 1 of the present invention provides a structural block diagram of an intelligent monitoring terminal for a base station oil generator. The intelligent monitoring terminal can be installed on a power distribution cabinet of a base station. see figure 1 , the intelligent monitoring terminal 100 includes: a detection module 110, a main control module 120 and a wireless communication module 130 based on NB-IOT (Narrow Band-Internet Of Things, narrowband Internet of Things). in,

[0025] The detection module 110 is connected with the oil generator of the base station (not shown in the figure), and is used to detect the power supply parameters of the oil generator of the base station to obtain the power supply parameter value; wherein, the power supply parameter value may include the start time of power generation, the end time of power generation, Generating duration, three-phase current value, three-phase voltage value, power generation, engine frequen...

Embodiment 2

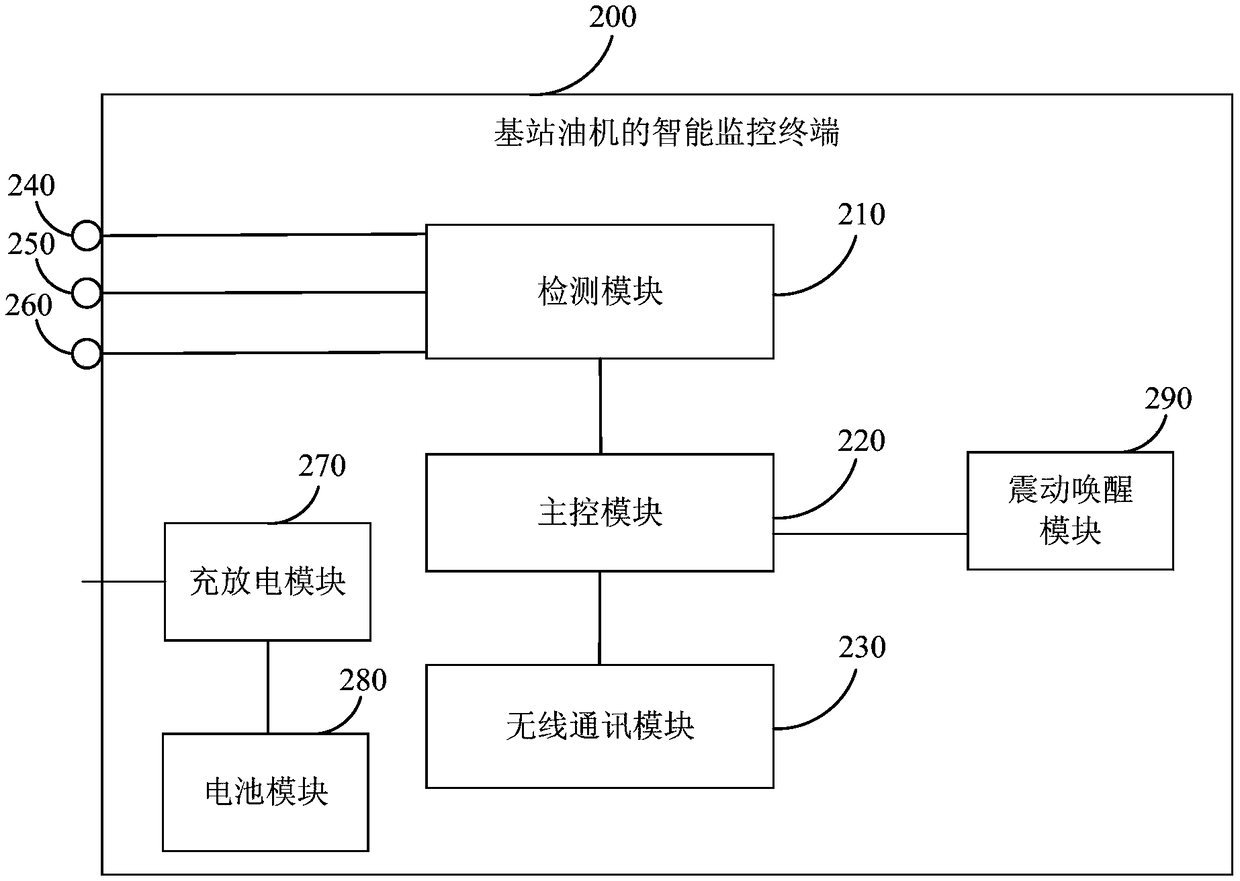

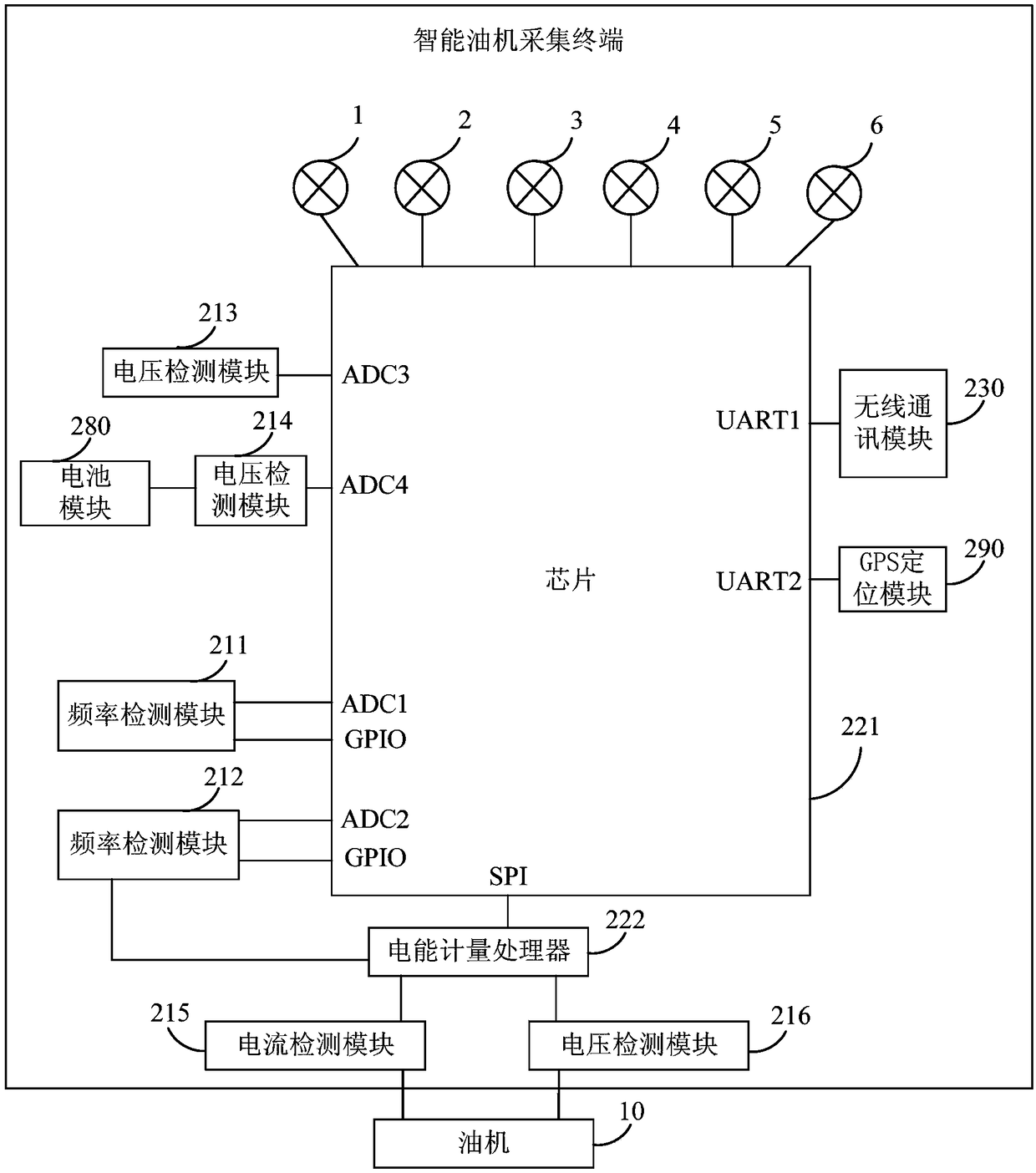

[0040] figure 2 The structural block diagram of an intelligent monitoring terminal of a base station oil machine provided by Embodiment 2 of the present invention. This embodiment optimizes the functions of the intelligent monitoring terminal on the basis of the above-mentioned embodiments, and the same or corresponding The explanation of terms will not be repeated here. see figure 2 , the intelligent monitoring terminal 200 provided in this embodiment includes: a detection module 210 , a main control module 220 , a wireless communication module 230 , a base station power distribution cabinet connection terminal 240 , an oil generator connection terminal 250 and a mains connection terminal 260 . in,

[0041] The detection module 210 is connected to the base station oil machine through the oil machine connection terminal 250, and is used to detect the power supply parameters of the base station oil machine to obtain the power supply parameter value;

[0042] The main contr...

Embodiment 3

[0062] Figure 4 It is a schematic flow chart of a control method of a base station diesel engine provided by Embodiment 3 of the present invention. The method of this embodiment can be executed by a control device of a base station diesel engine, and the device can be realized by means of software and / or hardware. It is generally integrated in the server of the background operator based on the NB-IOT cloud platform. refer to Figure 4 , the control method provided in this embodiment includes:

[0063] S310. Based on the preset communication network, acquire the power supply parameter values and location information of the base station oil machines respectively uploaded by the intelligent monitoring terminals of the multiple base station oil machines.

[0064] Exemplarily, the power supply parameters may include the start time of power generation, the end time of power generation, the duration of power generation, the three-phase current value, the three-phase voltage valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com