Magnetic assembly device for stator and rotor of permanent magnet motor and application method of magnetic assembly device

A technology for permanent magnet motors and rotors, applied in electromechanical devices, manufacturing motor generators, centering/balancing rotors, etc., can solve the problems of inapplicable assembly of large permanent magnet motors, achieve uniform air gaps, and avoid parts damage, simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

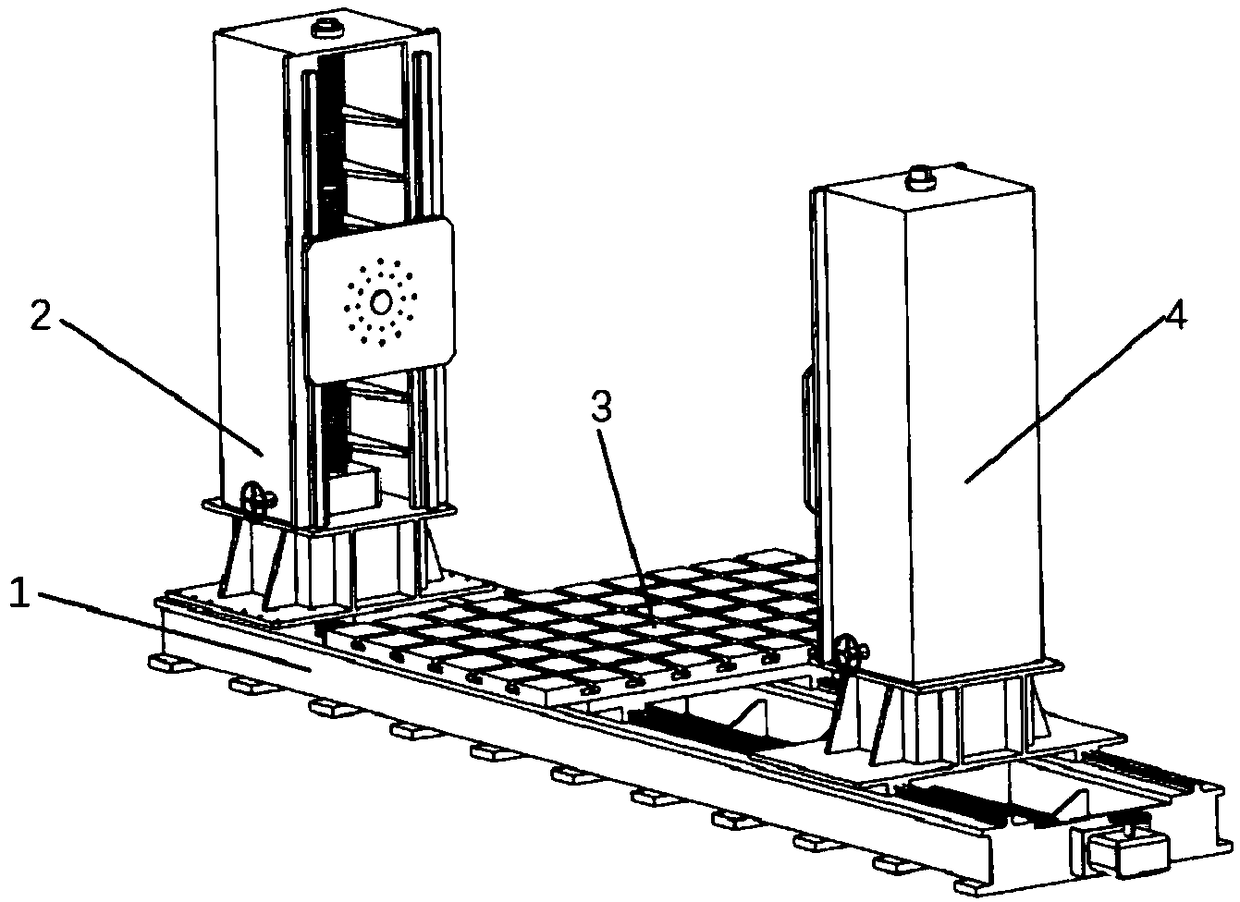

[0092] Such as figure 1 As shown: this embodiment discloses a permanent magnet motor stator and rotor magnetic assembly device, including: a device base 1 located in the motor assembly area, a fixed end gantry support 2, a mobile end gantry support 4, a movable stator Pallet 3, non-drive end extension shaft tooling 5 and drive end conversion shaft tooling 6.

[0093] Wherein, the device base 1 includes a first end and a second end.

[0094] The fixed-end gantry bracket 2 is fixedly arranged at the first end.

[0095] It should be noted that the fixed-end gantry bracket 2 described here is fixed to the first end of the device base 1 by fixing bolts.

[0096] The gantry bracket 4 at the moving end is arranged at the second end, and can move controllably along the length direction of the device base 1 .

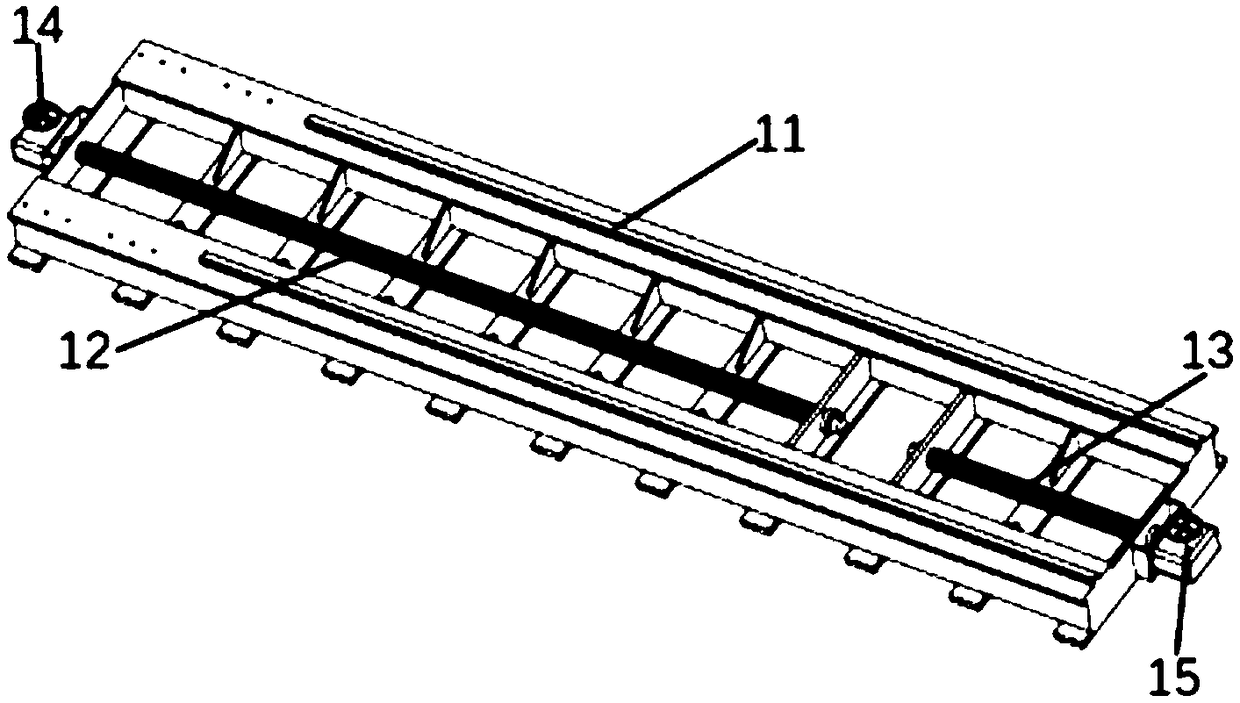

[0097] In detail, the mobile end gantry bracket 4 described here is connected to the second end of the device base 1 through the first linear guide rail group 11 and the seco...

Embodiment 2

[0164] This embodiment discloses a permanent magnet motor stator and rotor magnetic assembly device, which is used to realize the permanent magnet motor stator and rotor assembly.

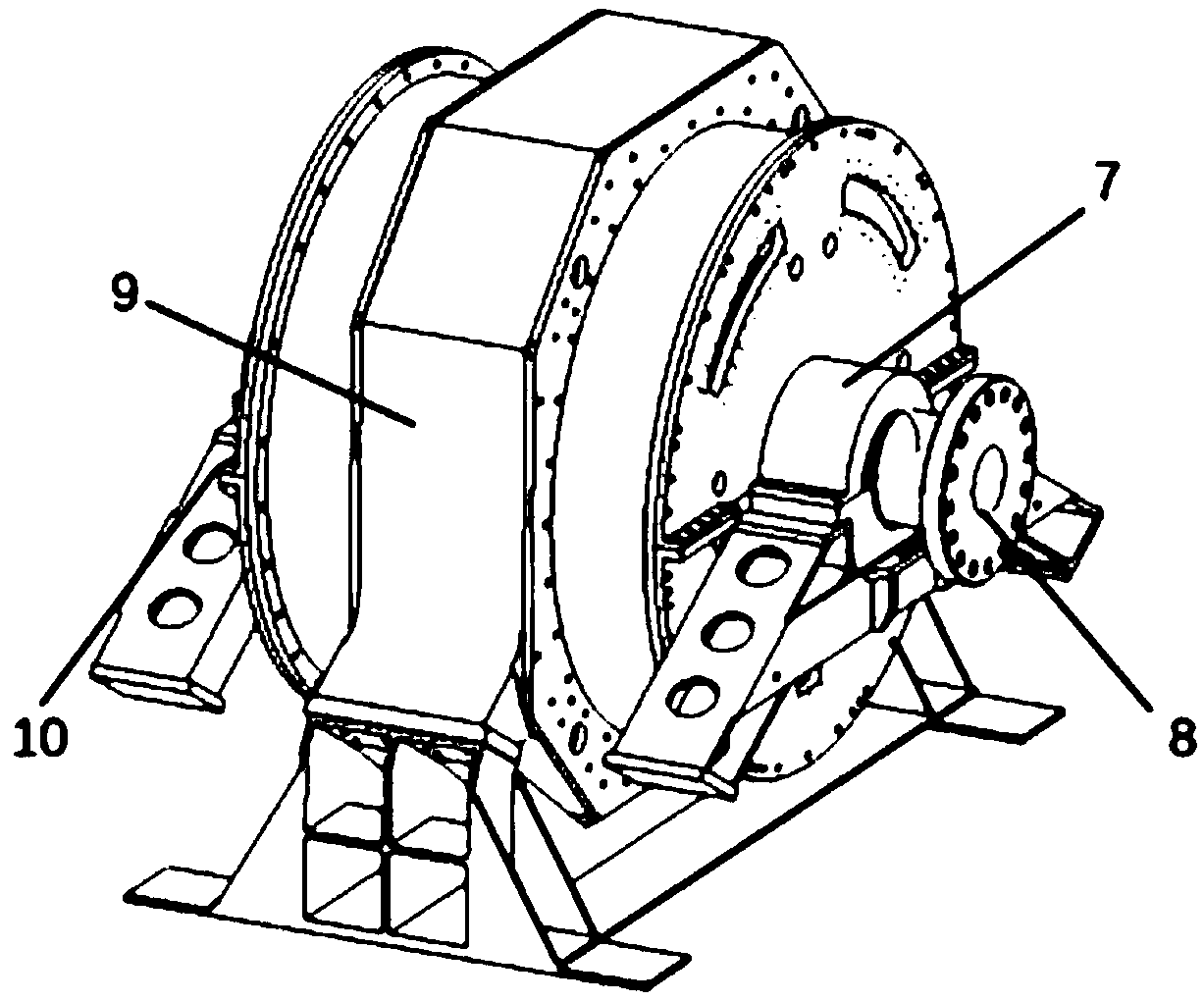

[0165] Specifically, the permanent magnet motor stator and rotor magnetic assembly device disclosed in this embodiment includes: a device base 1, a gantry support 2 at a fixed end, a movable stator tray 3, a gantry support 4 at a moving end, and an extended shaft tooling at a non-driving end 5. Drive end conversion shaft tooling 6, please refer to figure 1 and Figure 8 . A large permanent magnet motor is composed of a bearing shell structure driving end cover assembly 7, a rotor 8, a stator 9, and a bearing shell structure non-driving end cover assembly 10, please refer to figure 2 . The device base 1 is placed on the motor assembly site, and the fixed-end gantry bracket 2 is installed on the first end of the device base 1 . The movable stator tray 3 is connected to the top of the device base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com