Tail gas heated air circulating device of dry ammonium furnace

A technology of hot air circulation and exhaust gas, which is applied in the direction of combination devices, fluid heaters, lighting and heating equipment, etc., can solve the problems of waste of energy consumption resources, high environmental protection pressure, poor on-site environment, etc., to protect the environment, reduce energy consumption, The effect of increasing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

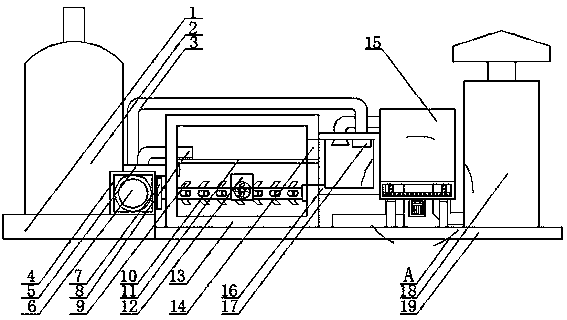

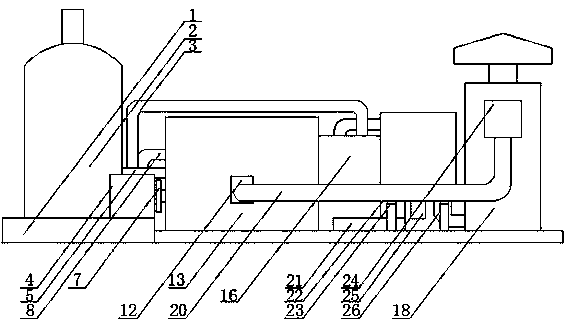

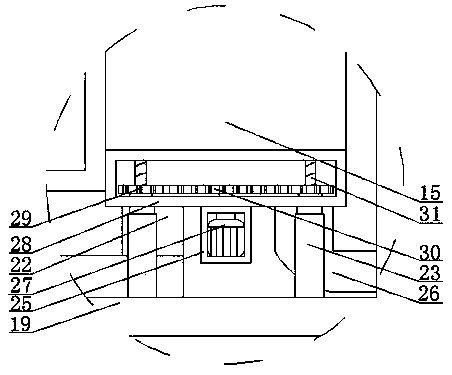

[0023] refer to Figure 1-4 , a dry ammonium furnace tail gas hot air circulation device, including a base plate 1 and a mounting plate 19, a heating box 13 is fixed on one side of the upper end of the mounting plate 19, and a cavity is provided in the heating box 13, and between the opposite side walls in the cavity A partition 11 is fixed together, and the partition 11 divides the cavity into a dust removal area and a heating area from top to bottom, and a first exhaust pipe 5 and a second exhaust pipe 8 run through one end side wall of the heating box 13, And one end of the second exhaust pipe 8 is connected to one end of the first exhaust pipe 5, and the exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com