Spray dust removal heat dissipation abrasive device

A grinding tool and grinding technology, which is applied in the direction of abrasives, manufacturing tools, metal processing equipment, etc., can solve the problems of damage, hazards, and impact on the service life of the workpiece to be processed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

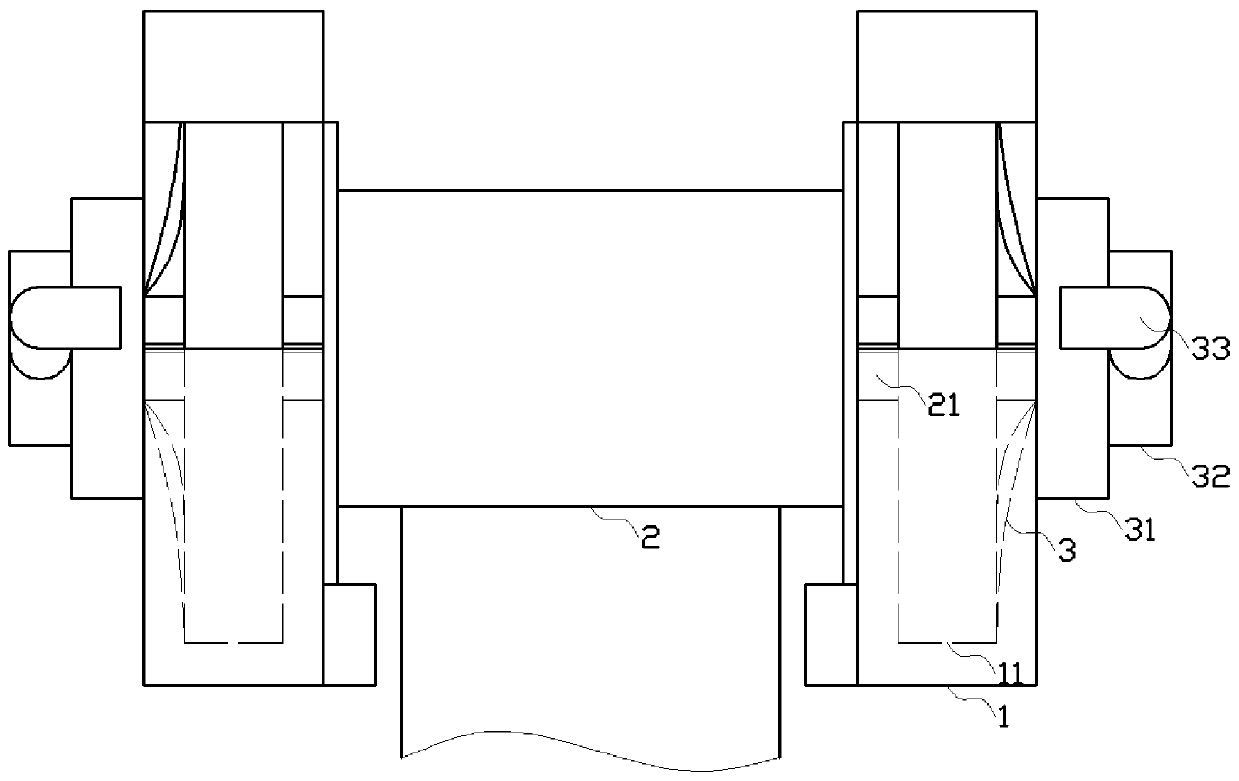

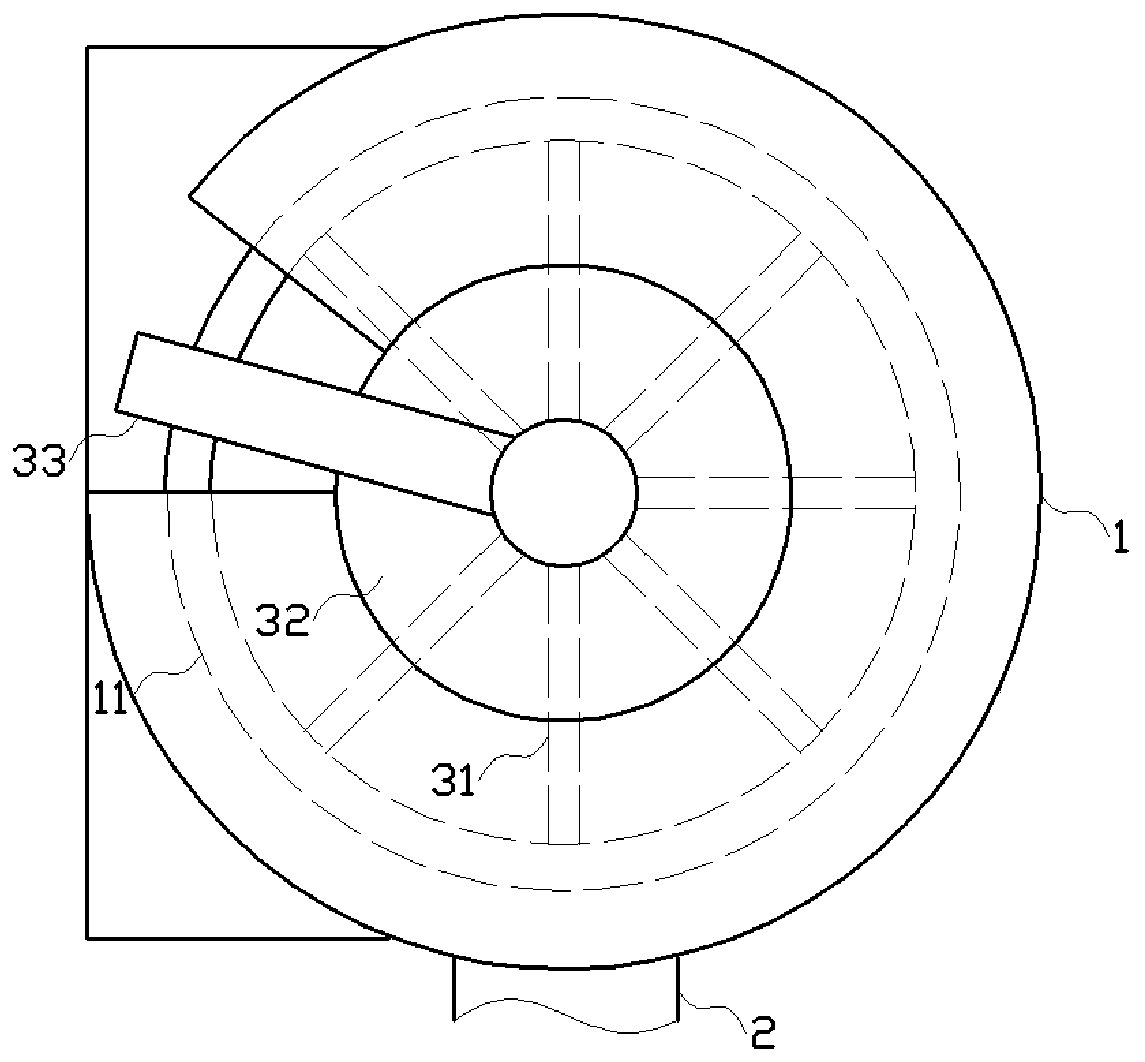

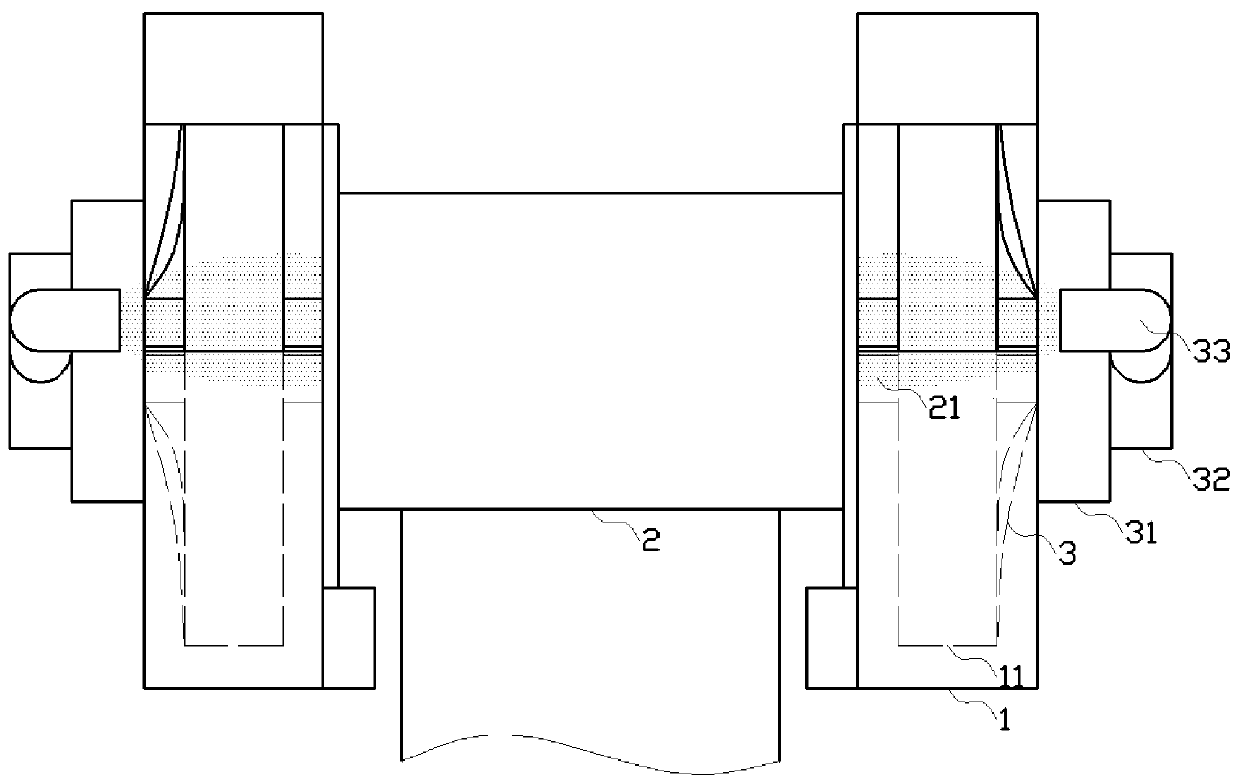

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown in the embodiment, the spray dust removal and heat dissipation grinding tool device is a kind of spraying water mist on the grinding surface when the grinding tool is grinding, so that the water mist and the dust particles generated by grinding are adsorbed together, and the water mist can A device that acts on the grinding surface and takes away the heat generated by grinding to achieve the effect of the magpie. It includes a grinding module 1, a motor module 2 and a spray module 3; the grinding module 1 includes a grinding wheel 11, the The grinding wheel 11 uses a grinding tool, and the grinding wheel 11 is provided with a matching shell, and the shell is provided with a fan-shaped opening, and the lower edge of the fan-shaped opening is on the same level as the axis of the shell , the axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com