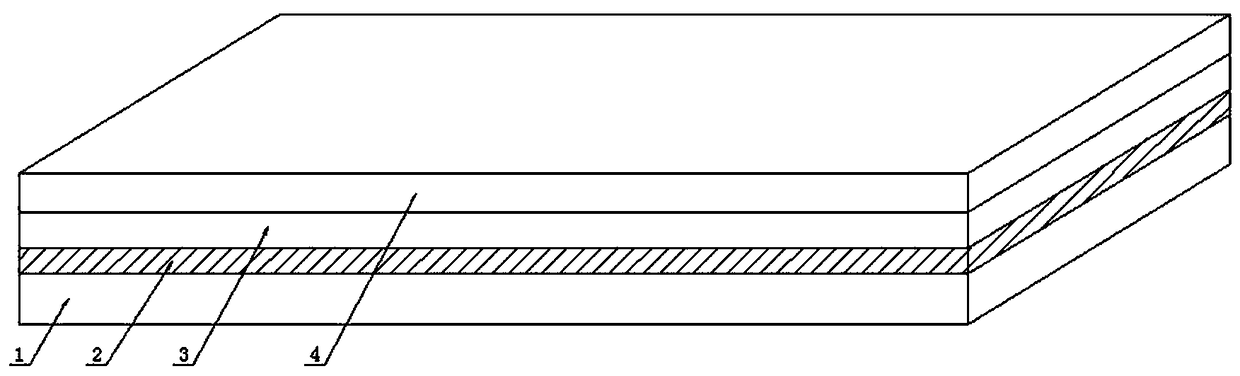

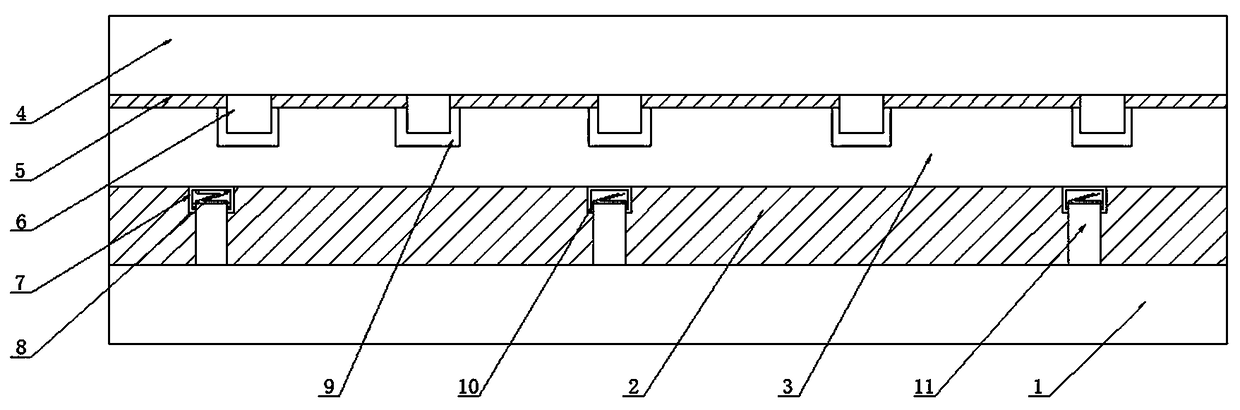

Composite flame retardant wood and production process thereof

A composite flame retardant and production process technology, which is applied in the direction of wood processing equipment, manufacturing tools, and wooden veneer joints, can solve the problems of halogen flame retardant restrictions, large environmental pollution, serious pollution, etc., to reduce vibration, The effect of good shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

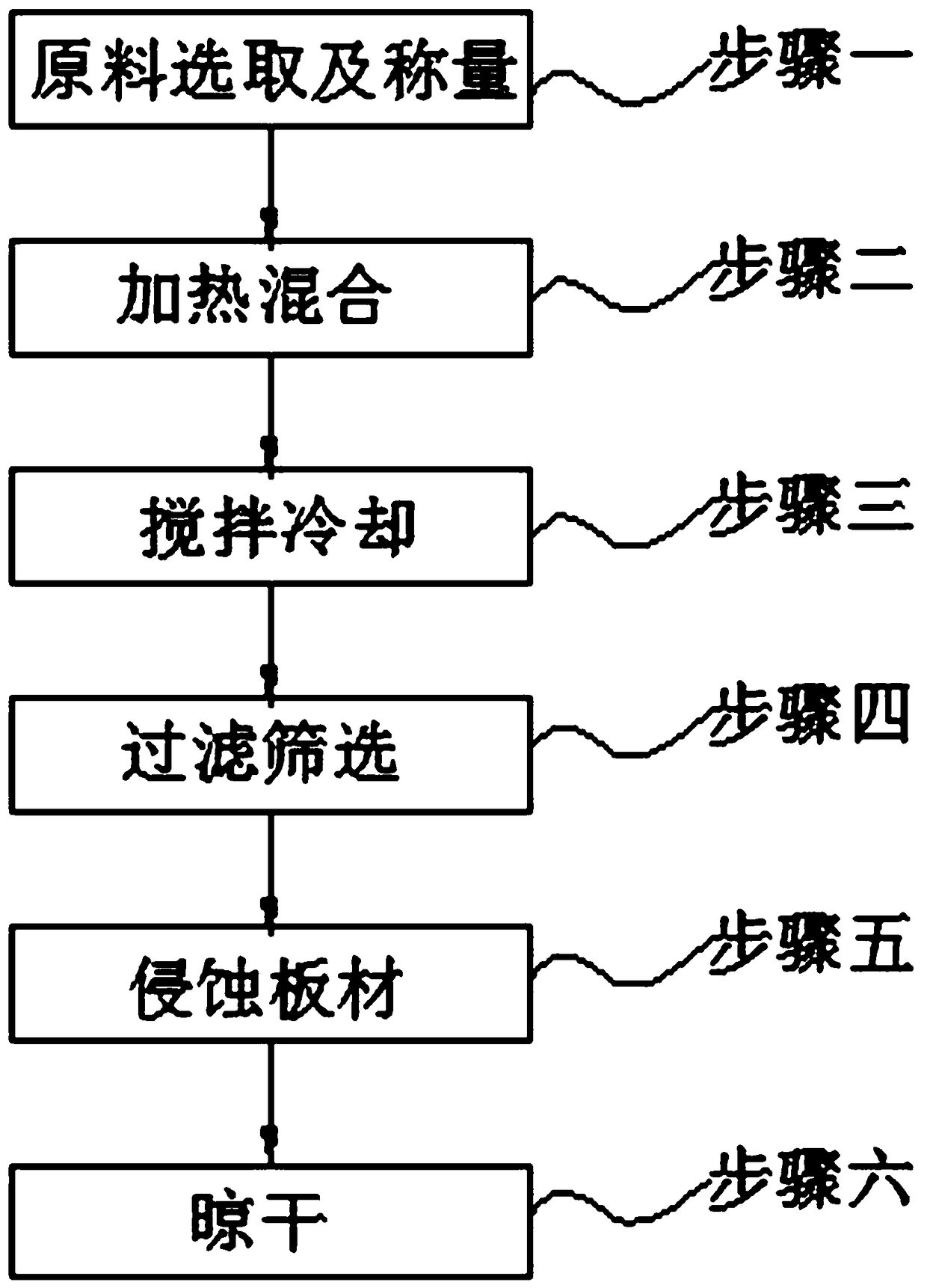

[0031] A composite flame-retardant wood production process, including the following steps, step 1, raw material selection and weighing; step 2, heating and mixing; step 3, stirring and cooling; step 4, filtering and screening; step 5, eroding the board; dry; Wherein in the above-mentioned step 1, according to raw material weight percentages are respectively: diamine hydrogen phosphate 20%, magnesium sulfate 20%, ammonium borate 30%, ammonium chloride 28%, defoamer 1%, dispersant 1% and A small amount of water, the defoamer is at least one of polyoxypropylene glyceryl ether, polyoxypropylene polyoxyethylene glyceryl ether and polydimethylsiloxane, and the dispersant is triethylhexyl phosphoric acid, sodium lauryl sulfate and At least one of methyl pentanol;

[0032] In the above-mentioned step two, a small amount of water is added to the reaction kettle, and then the diamine hydrogen phosphate, magnesium sulfate, ammonium borate, ammonium chloride, defoamer and dispersant weigh...

Embodiment 2

[0038] A composite flame-retardant wood production process, including the following steps, step 1, raw material selection and weighing; step 2, heating and mixing; step 3, stirring and cooling; step 4, filtering and screening; step 5, eroding the board; Dry;

[0039] Wherein in above-mentioned step 1, according to raw material weight percent respectively: diamine hydrogen phosphate 25%, magnesium sulfate 25%, ammonium borate 25%, ammonium chloride 24%, defoamer 0.5%, dispersant 0.5% and a small amount of water , the defoaming agent is at least one of polyoxypropylene glyceryl ether, polyoxypropylene polyoxyethylene glyceryl ether and polydimethylsiloxane, and the dispersant is triethylhexyl phosphoric acid, sodium lauryl sulfate and methyl At least one of pentanols;

[0040] In the above-mentioned step two, a small amount of water is added to the reaction kettle, and then the diamine hydrogen phosphate, magnesium sulfate, ammonium borate, ammonium chloride, defoamer and dispe...

Embodiment 3

[0046]A composite flame-retardant wood production process, including the following steps, step 1, raw material selection and weighing; step 2, heating and mixing; step 3, stirring and cooling; step 4, filtering and screening; step 5, eroding the board; Dry;

[0047] Wherein in the above-mentioned step 1, according to raw material weight percent respectively: 30% of diamine hydrogen phosphate, 29% of magnesium sulfate, 20% of ammonium borate, 20.8% of ammonium chloride, 0.1% of defoamer, 0.1% of dispersant and a small amount of water , the defoaming agent is at least one of polyoxypropylene glyceryl ether, polyoxypropylene polyoxyethylene glyceryl ether and polydimethylsiloxane, and the dispersant is triethylhexyl phosphoric acid, sodium lauryl sulfate and methyl At least one of pentanols;

[0048] In the above-mentioned step two, a small amount of water is added to the reaction kettle, and then the diamine hydrogen phosphate, magnesium sulfate, ammonium borate, ammonium chlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com