Structural wood-based panel with hidden enhanced stripe and preparation method and combined wall body thereof

A structural board and wood-based technology, applied in the field of wood-based structural boards and their preparation methods, and composite walls, can solve problems such as uneven stress and damage to wood-based plywood, achieve improved mechanical properties, increase utilization, and be feasible strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

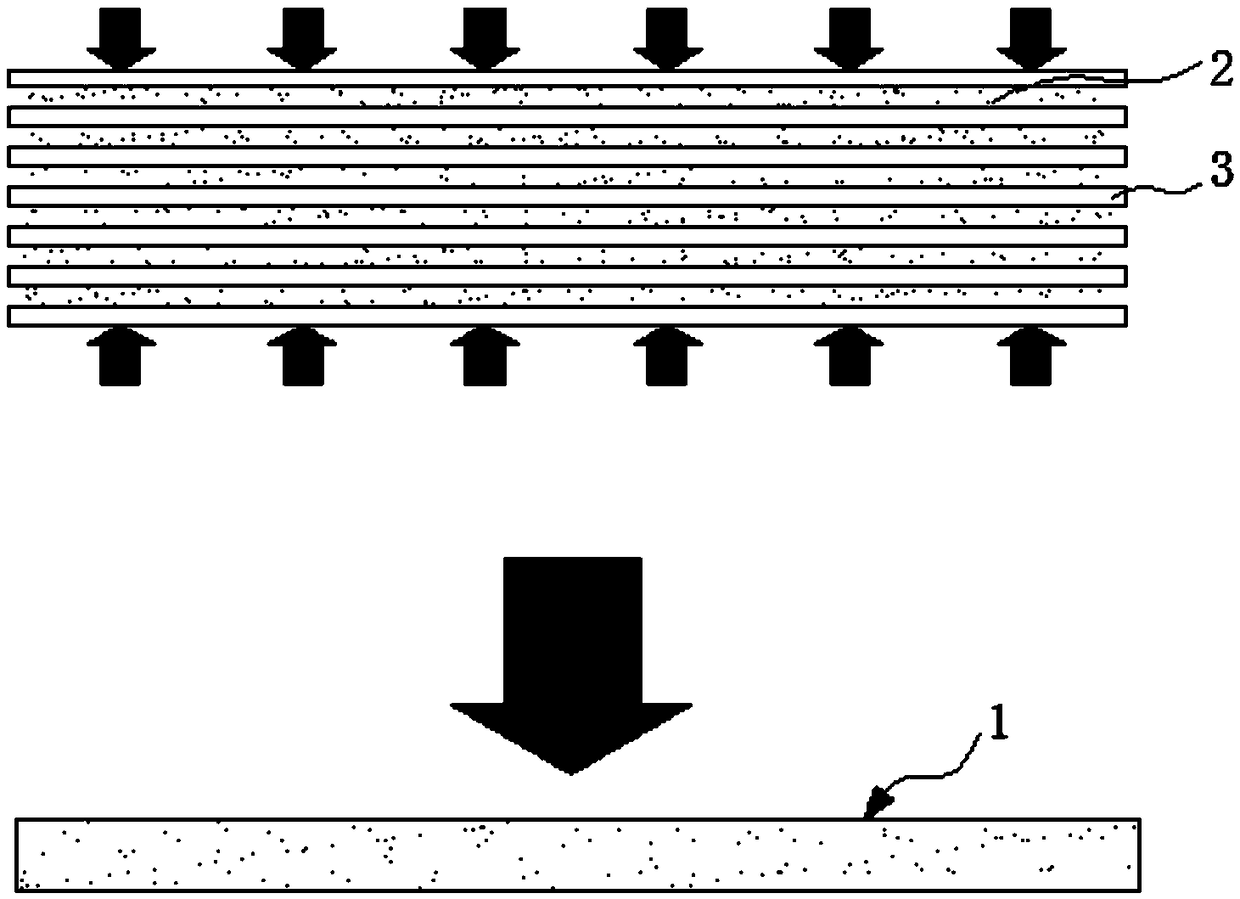

Method used

Image

Examples

Embodiment 1

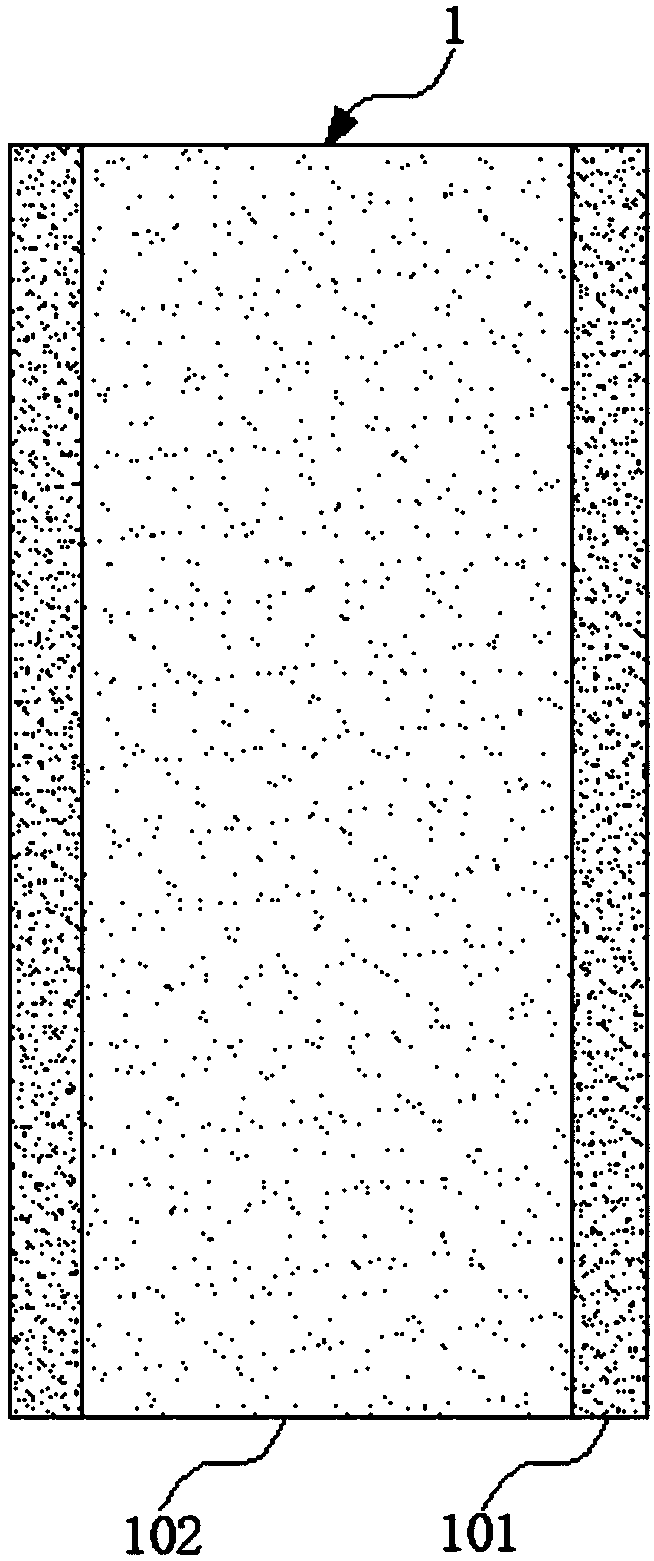

[0039] Such as image 3 As shown, the wood-based structural board with implicit reinforcement strips is a wood-based plywood, which includes a high-density area 101 and a low-density area 102 in the horizontal direction of the thickness of the wood-based plywood, and the high-density area 101 is set at the low-density area. On both sides of the region 102 , the density of the high-density region 101 is higher than that of the low-density region 102 . In the wood-based plywood high-density area 101 , there are short boards 4 sandwiched between the two veneer boards 3 in the horizontal direction perpendicular to the thickness.

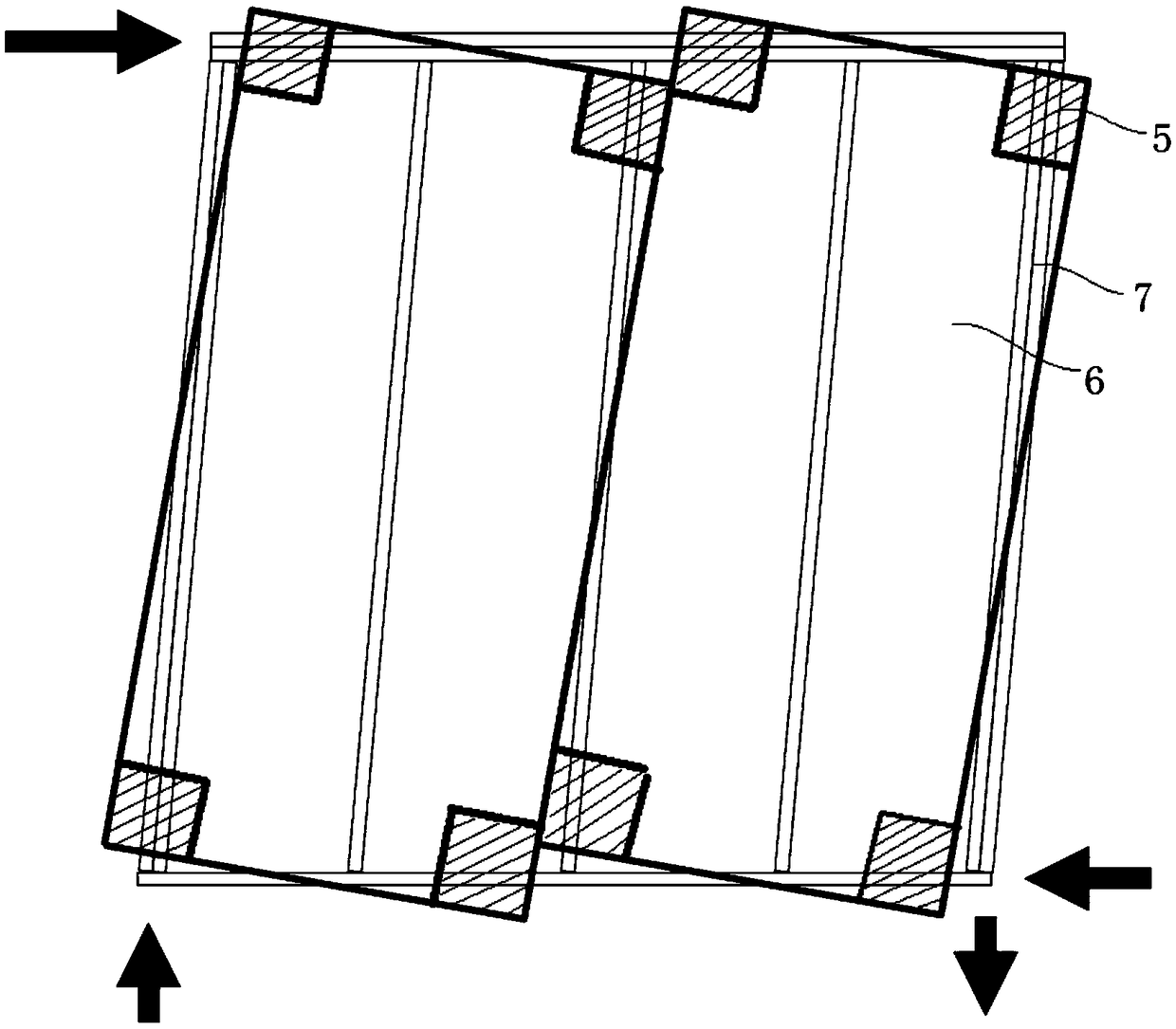

[0040] Such as figure 2 As shown, when the shear wall made of conventional wood-based plywood is damaged by horizontal action, the corners of the board are prone to damage, easy to pull out nails, or premature yield due to stress concentration at the corners, while the central area The plate is still intact, and this part of the intact plate has not f...

Embodiment 2

[0042]The structure of the wood-based structural board with hidden reinforcing strips in this embodiment is basically the same as that in Embodiment 1. Furthermore, the density of the high-density area 101 in this embodiment is 1.1-1.7 times that of the low-density area 102 .

[0043] Specifically, the average density of the high-density region 101 of the present invention is maintained at 0.65-0.85 g / cm 3 Within the range, the density of the low-density area 102 ranges from 0.5 to 0.6 g / cm 3 , which not only meets the strength requirements after density enhancement, but also saves materials. Although according to the proportional relationship between density and strength, if simply consider increasing the density endlessly to increase the strength, it will not only increase the complexity of the preparation process and the cost of materials, but also cannot meet the use requirements in practical applications. From the perspective of reinforced area, if only the entire board ...

Embodiment 3

[0045] The basis for the division of the high-density area 101 and the low-density area 102 in the present invention comes from the previous research on wood-based plywood. According to the failure mode of the wood-frame composite wall when it is subjected to horizontal force and the simulation results of finite elements, the wood-based plywood is used as the cladding When the panel is damaged, the corner and edge areas are the most damaged, and the stress they bear is 3 to 7 times that of the central area of the panel. Such as figure 2 As shown, when the shear wall is damaged by the horizontal lateral force, the four corners of the cladding panel and the wall skeleton composed of stud columns 7 will have the problem that the nails are easy to pull out, which is easier to damage than the middle, through the finite element simulation It is very clear to see the stress distribution of the cladding panels during the failure process of the shear wall. The four corners of the cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap