High-elastic seamless-fitting down feather fabric

A down fabric and bonding technology, applied in the field of textile fabrics, can solve the problems of poor air permeability, low elasticity, poor wearing comfort, etc., achieve excellent air permeability, good elasticity, and improve wearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

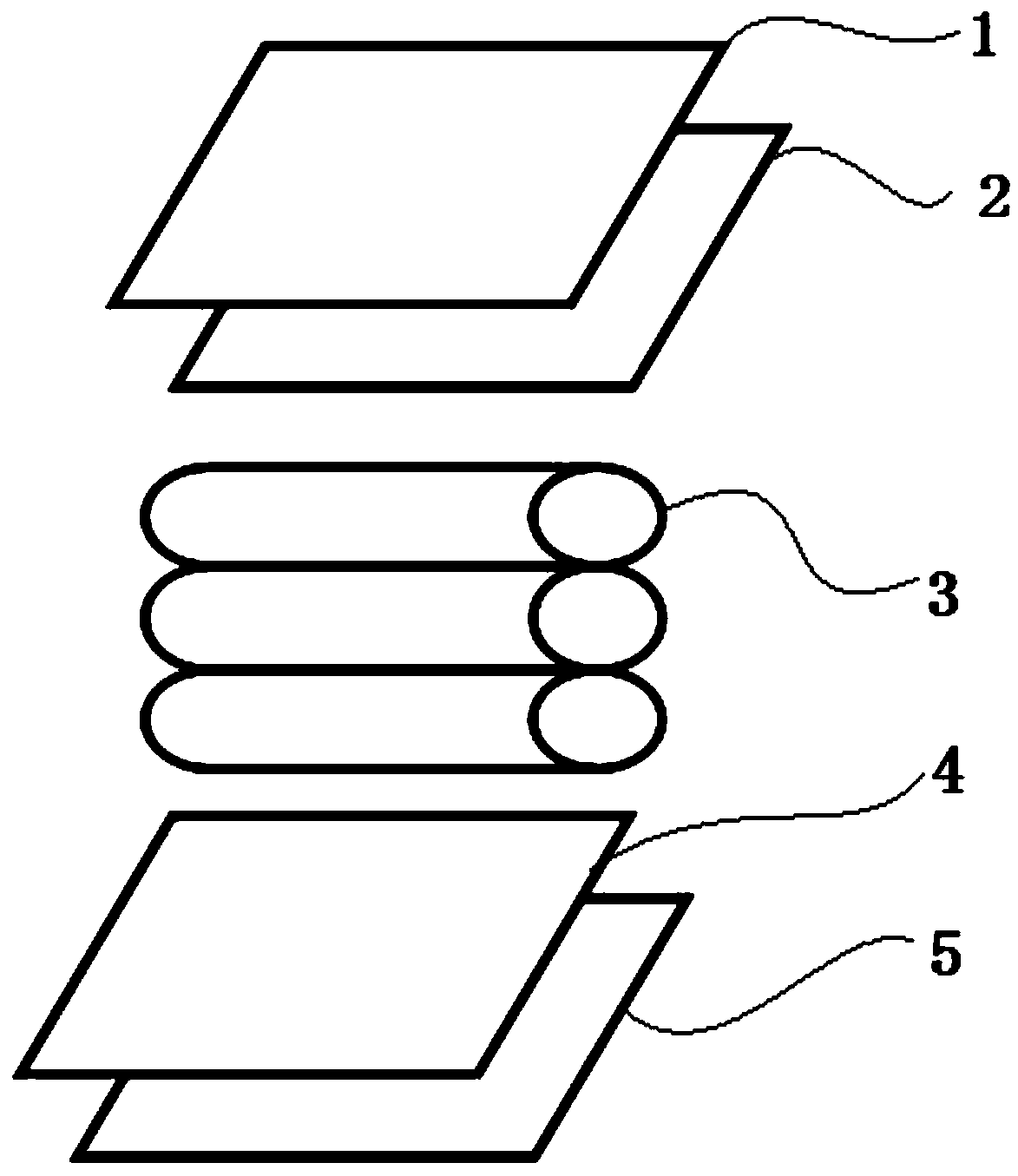

[0034] Such as figure 1 As shown, a high-elastic seamlessly bonded down fabric, which adopts a seamless bonding process, includes a face cloth layer 1, a first film layer 2, a tubular knitted layer 3, and a second film layer 4 from top to bottom. , base cloth layer 5; face cloth layer 1 is connected with tubular knitted layer 3 by the first film layer 2, and base cloth layer 5 is connected base cloth and tubular knitted layer 3 by the second film layer 4; face cloth layer 1 is breathable Composite fabric; the tubular knitted layer 3 includes a plurality of tubular bodies 304 and an intermediate connecting portion 303 connecting the tubular bodies; the base fabric layer 5 is a breathable elastic fabric.

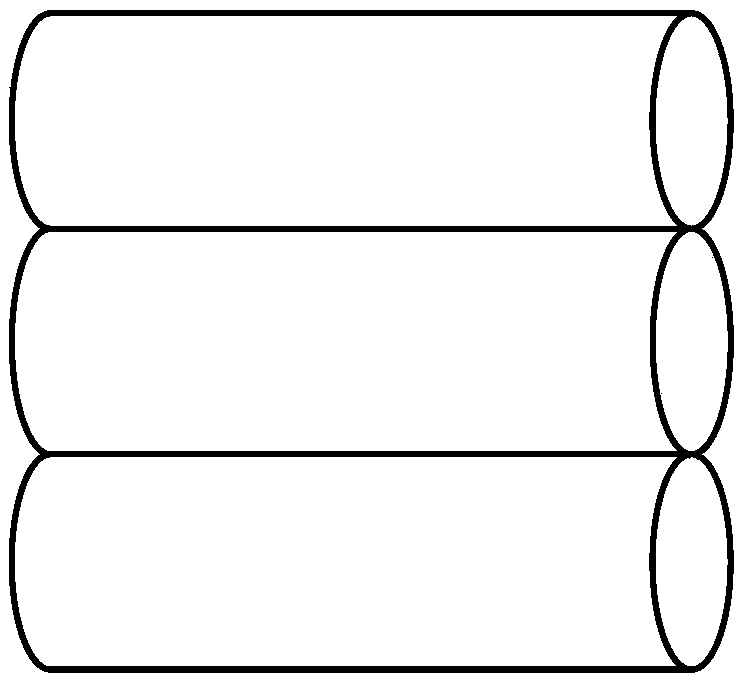

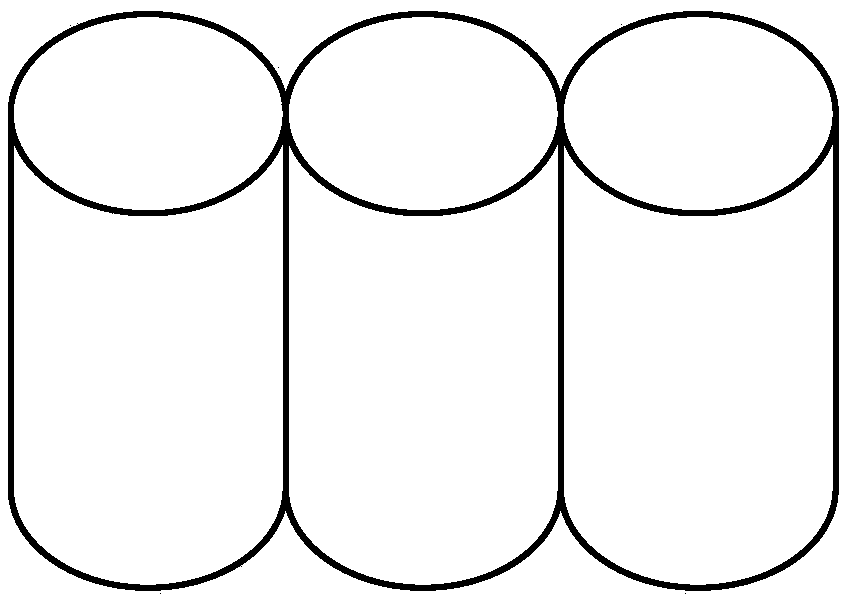

[0035] Such as Figure 4As shown, the tubular knitted layer 3 is woven on a jacquard machine or an ordinary circular weft machine. The tubular body 304 is formed by only using single-sided loops through needle selection, and the middle connecting part 303 is made of double-si...

Embodiment 2

[0042] A high-elastic seamlessly laminated down fabric, the fabric adopts a seamless lamination process, and sequentially includes a face fabric layer 1, a first film layer 2, a tubular knitted layer 3, a second film layer 4, and a base fabric from top to bottom Layer 5; the face cloth layer 1 is connected with the tubular knitted layer 3 through the first film layer 2, and the base cloth layer 5 is connected with the tubular knitted layer 3 through the second film layer 4; the face cloth layer 1 is a breathable composite fabric; The tubular knitted layer 3 includes a plurality of tubular bodies 304 and an intermediate connecting portion 303 connecting the tubular bodies; the base fabric layer 5 is a breathable elastic fabric.

[0043] Such as Figure 5 As shown, the tubular knitted layer 3 is a tubular double-layer fabric formed by computer needle selection or knitting needle arrangement; the tubular knitted layer 3 includes an upper layer fabric 301, a lower layer fabric 302...

Embodiment 3

[0046] A method for preparing a high-elastic seamlessly laminated down fabric, characterized in that it comprises the following steps:

[0047] 001. Preparation of tubular knitted layer: prepare tubular knitted layer by needle selection of jacquard machine or triangular arrangement of ordinary circular knitting machine and yarn arrangement, or form tubular double-layer fabric by arranging knitting needles.

[0048] 002. Refining of tubular knitted layer: the refining temperature can be set at 40-85°C, and a certain proportion of degreasing agent, chelating dispersant and nonionic surfactant can be added;

[0049] 003, the middle shaping of the tubular knitted layer: the processing temperature is set at 190-195°C, the speed is 0-25M / MIN, and the wind speed is 40HZ;

[0050] 004. Dyeing: Dyeing the face fabric layer, tubular knitted layer and base fabric layer at a dyeing temperature of 130-135°C;

[0051] 005, upper setting, the surface cloth layer, the tubular knitted layer a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Water pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com